Method of preparing anticold grain based on ultrasound wave auxiliary extraction technology

An auxiliary extraction and ultrasonic technology, applied in anti-infective drugs, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve problems affecting extraction efficiency and drug quality, and improve equipment throughput and efficiency. The effect of less, convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The best technical solutions obtained are:

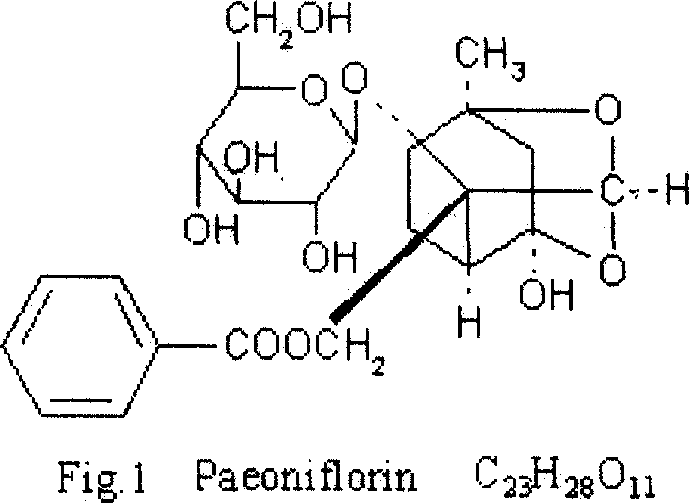

[0015] The dried honeysuckle, red peony root and cotton horse Guanzhong (weight ratio 3:3:1) are crushed, sieved (0.45 μm) as materials, mixed with water, and the volume ratio of material to liquid is 1:5-7. Ultrasonic power: 100W; Ultrasonic frequency: 25kHz; Ultrasonic action mode: Other excitation ultrasonic sounding device, radial vibration columnar transducer; Ultrasonic action time: 40min; Extraction temperature: 45°C; Stirring method: Airlift stirring; Liquid filtration, concentrated to a relative density of 1.08-1.16, add ethanol to 50% alcohol content, stir evenly, place overnight, filter, recover ethanol, concentrate, in extract flow rate of 4-6 (ml / min), atomization Spray drying under a pressure of 1-2 (kg) to obtain medicinal powder granules. According to the above-mentioned method, the yield of medicinal powder granules is 32%, and the content of paeoniflorin is 5.92%, which is 32% and 30.9% higher than the yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com