Integrated ring shaped anaerobic biogas generating pit

A biogas digester and anaerobic pond technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of poor sewage treatment and anti-corrosion effect, poor sealing performance, and long construction period, so as to reduce the chance of leakage and facilitate installation The effect of construction and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

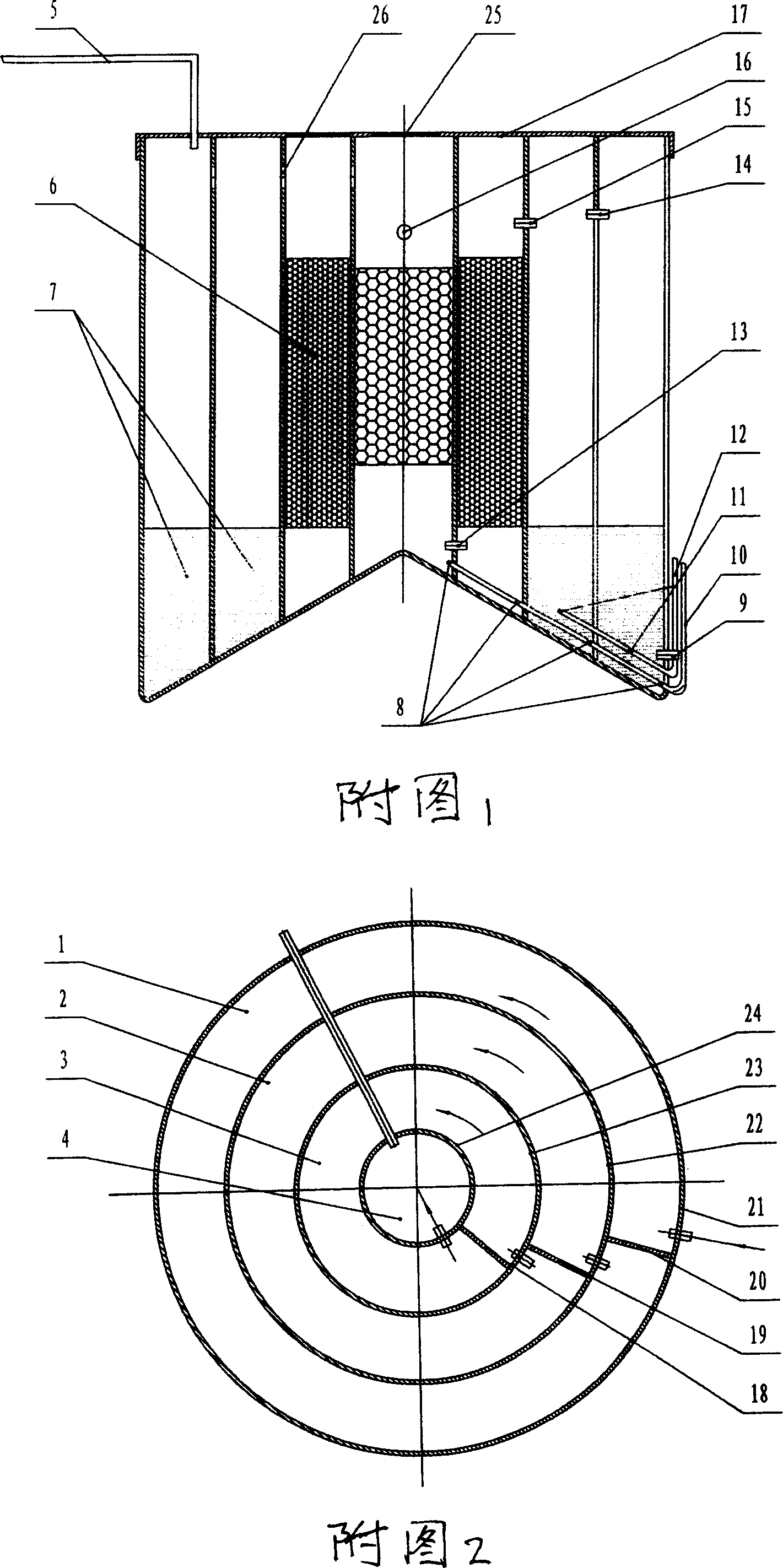

[0015] 1. As shown in Figures 1 and 2; the primary anaerobic chamber (1), the secondary anaerobic chamber (2), the primary biological filtration chamber (3), and the secondary biological filtration chamber (4) are made of fiberglass Ring-shaped integrated structure, sewage inlet and outlet are installed in each room, and a water outlet (18) leading to the outside of the annular anaerobic tank is also installed in the secondary biological filter room (4), and the sludge collection pipe (10) An external sludge pump is used for sludge discharge; at the same time, a compressed biogas branch pipe (11) is installed at the bottom of the inclined pool, and the compressed biogas branch pipe (11) is connected to the compressed biogas main pipe (12) to lead to the biogas storage device.

[0016] 2. A water inlet (9) is provided on the primary anaerobic chamber wall (21), and the primary anaerobic chamber baffle (20) is placed on the water inlet (9) and the secondary anaerobic chamber (1) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap