Microwave oven sintering method of producing silicon nitride ceramics heater and special equipment thereof

A technology of silicon nitride ceramics and special equipment, applied in the field of microwave oven sintering preparation, to achieve high production efficiency, short constant temperature time, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Microwave sintering of a silicon nitride ceramic heating element green body with dry-pressed buried wire.

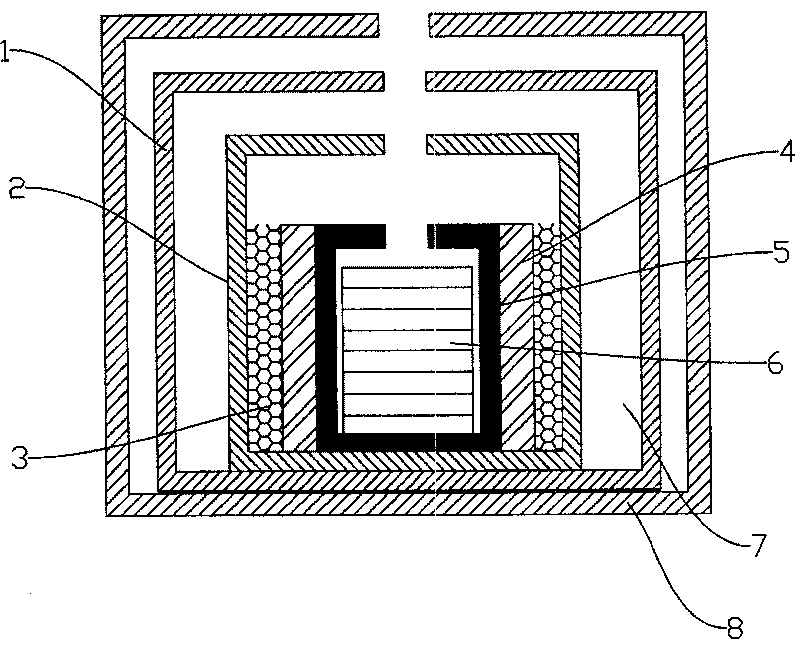

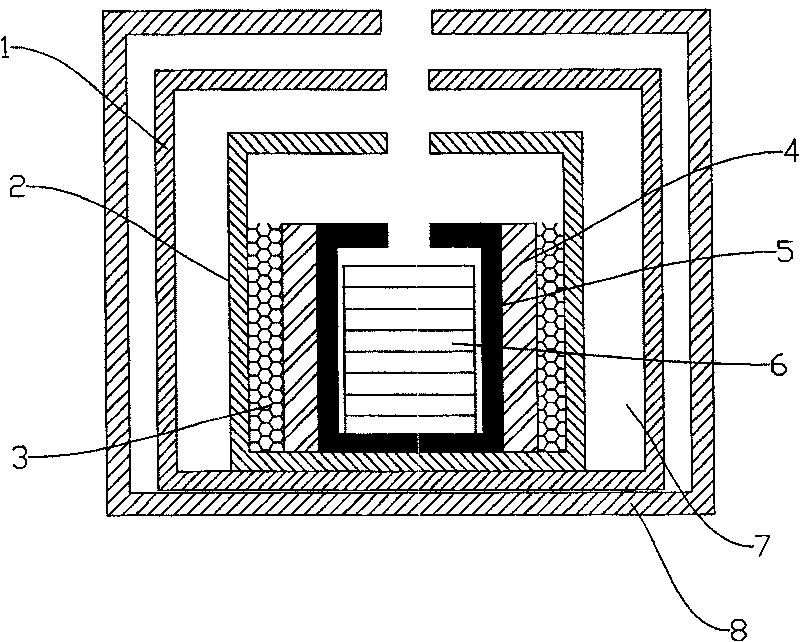

[0020] The sintering special equipment adopted in this embodiment is as figure 1 shown in . The special equipment includes a microwave oven body 8 and a corundum crucible 5, in which a special insulation body for sintering is arranged, and the special insulation body for sintering includes: the outermost fiber insulation body 1, the second outer layer Layer insulation body 2, auxiliary heating plate 4 and fiber insulation ball filling layer 3; described corundum crucible is aluminum oxide Al 2 o 3 Made of materials, the auxiliary heating plate is made of silicon carbide SiC material, and the fiber insulation ball is made of alumina Al 2 o 3 Made of materials, the insulation body of the second outer layer is magnesium aluminum spinel-lanthanum chromate MgAl 2 o 4 -LaCrO 3 Material production; between the auxiliary heating plate 4 and the thermal i...

Embodiment 2

[0023] Example 2: Microwave sintering of silicon nitride ceramic heating element green body with dry-pressed buried wire.

[0024] First, the ceramic green body of the silicon nitride ceramic heating element made of dry-pressed buried wire made by raw material preparation, blank preparation and debinding process is put into alumina Al 2 o 3 In the corundum crucible 5, then the alumina Al 2 o 3 Corundum crucible with auxiliary heating plate made of silicon carbide SiC, alumina Al 2 o 3 Fiber insulation ball, magnesium aluminum spinel - lanthanum chromate MgAl 2 o 4 -LaCrO 3 次 Insulation body, aluminum oxide Al 2 o 3 The sintering special insulation body composed of fiber insulation body is put into the 2.45GHz multi-mode reaction chamber microwave sintering device as a whole. The microwave oven is first vacuumed to 10Pa, and then filled with 99.9% N 2 , repeat the above-mentioned vacuum pumping and N filling four times 2 program, to the microwave oven cavity N 2 The...

Embodiment 3

[0026] Example 3: Microwave sintering of silicon nitride ceramic heating element green body with film rolling and silk printing.

[0027] First, put the silicon nitride ceramic heating element green body of rolling film and silk screen printing made by raw material preparation, blank preparation and degumming process into alumina Al 2 o 3 A corundum crucible, then alumina Al 2 o 3 Corundum crucible with auxiliary heating plate made of silicon carbide SiC, alumina Al 2 o 3 Fiber insulation ball, magnesium aluminum spinel - lanthanum chromate MgAl 2 o 4 -LaCrO 3次 Insulation body, aluminum oxide Al 2 o 3 The sintering special insulation body composed of fiber insulation body is put into the 2.45GHz multi-mode reaction chamber microwave sintering device as a whole. First, the microwave oven is evacuated to 10Pa, and then filled with N 2 , repeat the above-mentioned vacuuming and filling with N three times 2 program, to the microwave oven cavity N 2The content is higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com