Technique for reverting ironmaking by comprehensive utilization of fusion of coal gas and small ore

A technology for reducing iron and gas, applied in the direction of reducing gas emissions, furnace types, furnaces, etc., can solve the problems of low gas utilization, low production efficiency, and reduced reaction efficiency of multi-stage fluidized beds, and achieve the goal of preventing carbon precipitation reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

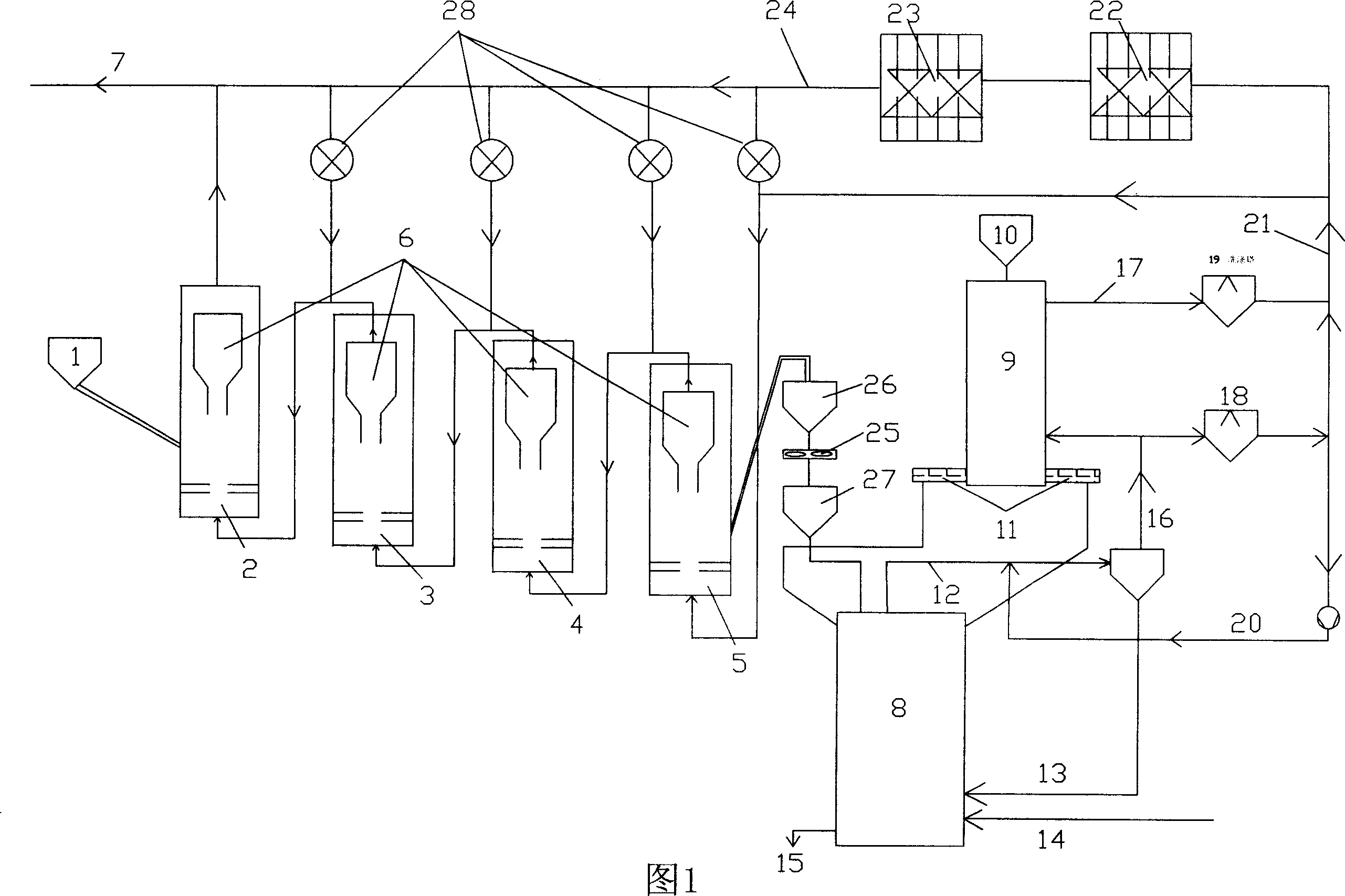

Embodiment 1

[0028] Referring to Fig. 1, powdered ore (particle size8mm) materials are respectively installed in powder ore silo 1 and lump ore silo 10, and are filled with lump coal and lump ore for melting and gasification Oxygen 14 (purity > 99%) is injected into the furnace 8. Under high temperature conditions, the coal in the melting and gasification furnace 8 forms semi-coke and produces a large amount of reducing export gas 12. The outlet gas 12 passes through the cyclone dust collector 16 to separate the gas The dust 13 in is returned to the melter-gasifier 8 for reaction. Part of the gas that has been dedusted by the cyclone is passed into the shaft furnace 9 to reduce the lump ore added from the lump ore silo 10, and DRI with a reduction degree of 70-95% of the lump ore reduced by the shaft furnace is added through the screw feeder 11 Separation of the final reduced slag and iron 15 in the melting and gasifier to obtain qualified molten iron whose quality is comparable to that of...

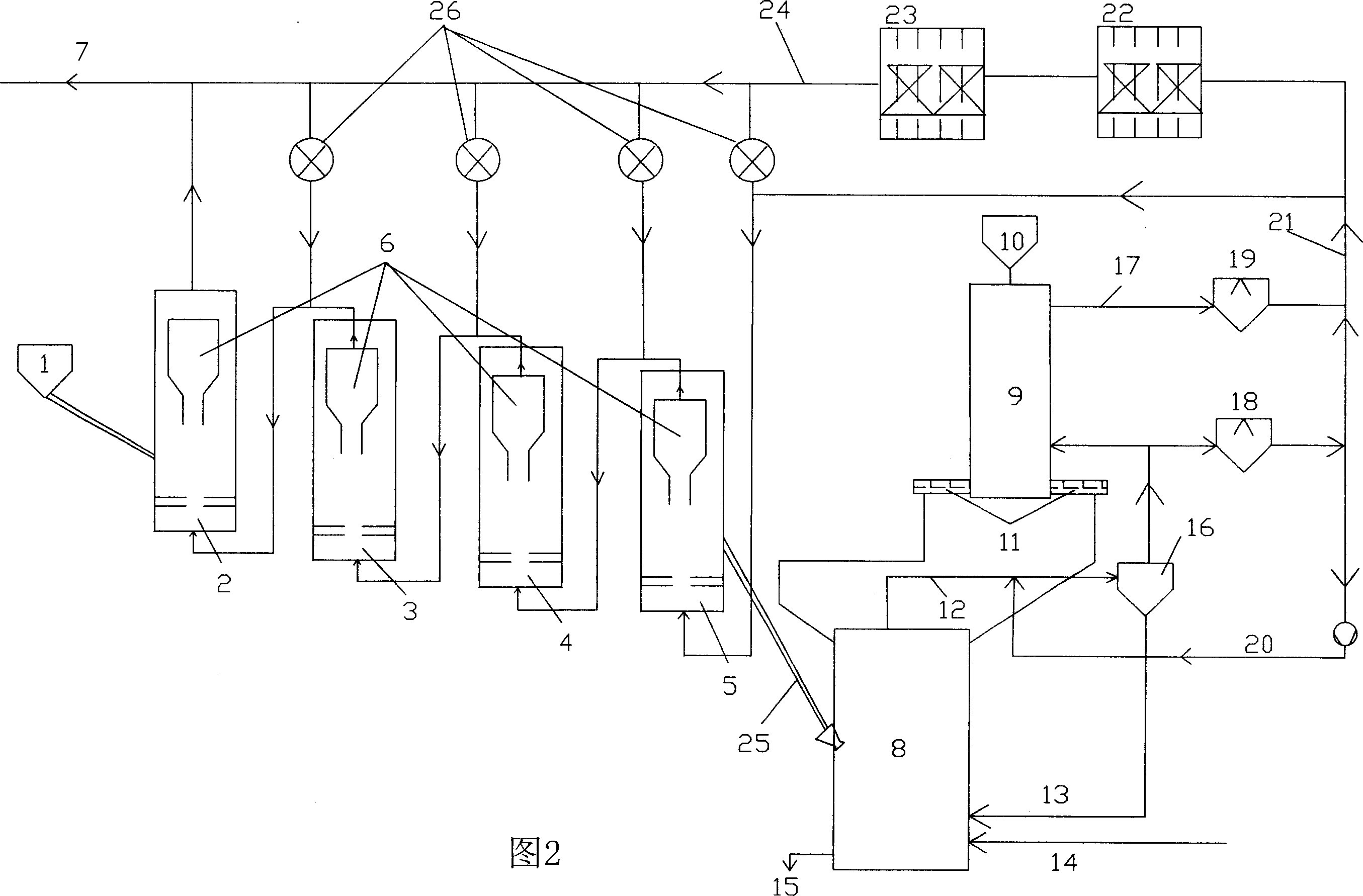

Embodiment 2

[0032] Referring to Fig. 2, powdered ore (particle size8mm) materials are respectively installed in powder ore silo 1 and lump ore silo 10, and are filled with lump coal and lump ore for melting and gasification Oxygen 14 (purity > 99%) is injected into the furnace 8. Under high temperature conditions, the coal in the melting and gasification furnace 8 forms semi-coke and produces a large amount of reducing export gas 12. The outlet gas 12 passes through the cyclone dust collector 16 to separate the gas The dust 13 in is returned to the melter-gasifier 8 for reaction. Part of the gas that has been dedusted by the cyclone is passed into the shaft furnace 9 to reduce the lump ore added from the lump ore silo 10, and DRI with a reduction degree of 70-95% of the lump ore reduced by the shaft furnace is added through the screw feeder 11 Separation of the final reduced slag and iron 15 in the melting and gasifier to obtain qualified molten iron whose quality is comparable to that of...

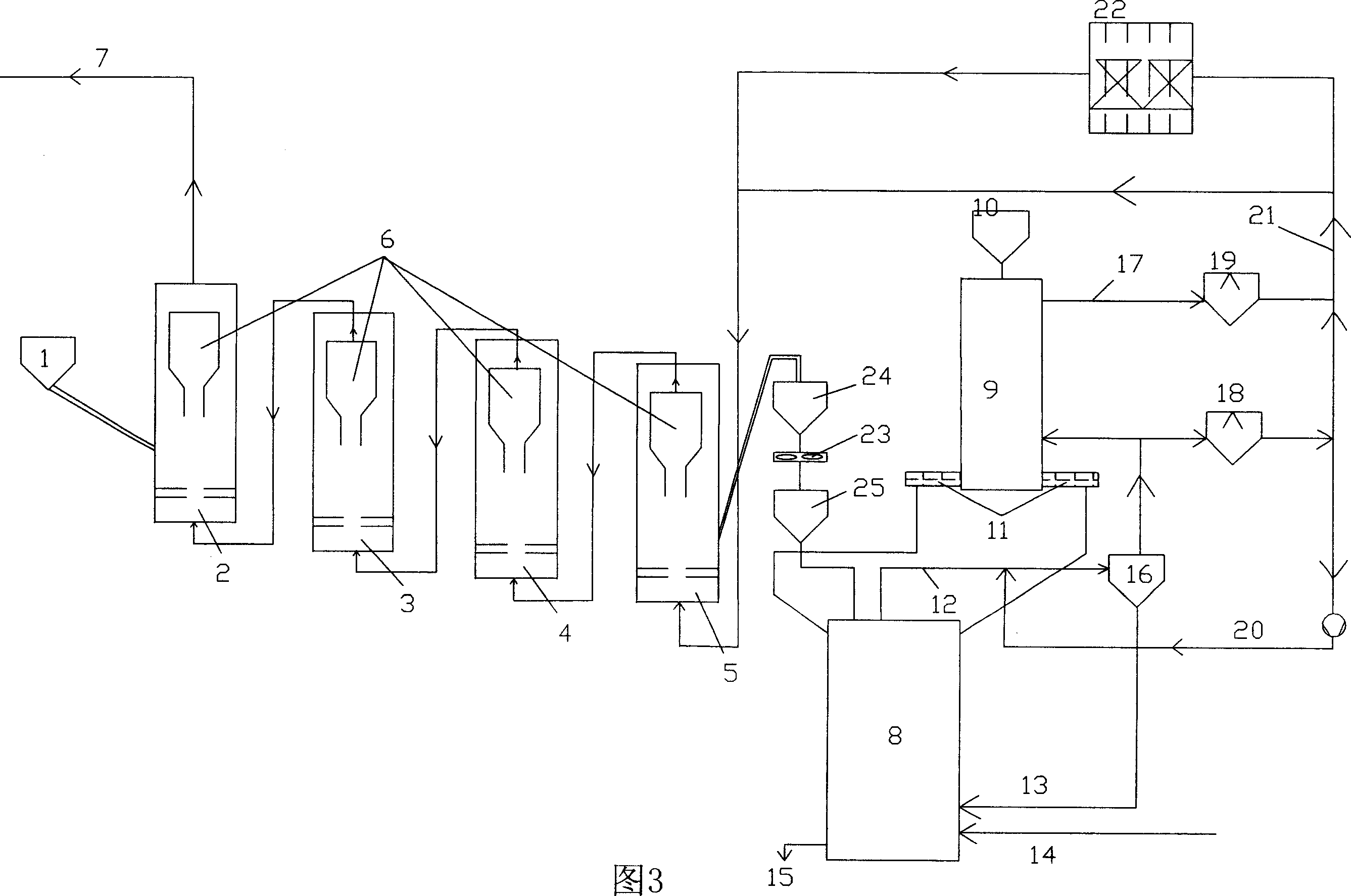

Embodiment 3

[0037] Referring to Fig. 3, powdered ore (particle size8mm) materials are respectively installed in powder ore silo 1 and lump ore silo 10, and are filled with lump coal and lump ore for melting and gasification Oxygen 14 (purity > 99%) is injected into the furnace 8. Under high temperature conditions, the coal in the melting and gasification furnace 8 forms semi-coke and produces a large amount of reducing export gas 12. The outlet gas 12 passes through the cyclone dust collector 16 to separate the gas The dust 13 in is returned to the melter-gasifier 8 for reaction. Part of the gas that has been dedusted by the cyclone is passed into the shaft furnace 9 to reduce the lump ore added from the lump ore silo 10, and DRI with a reduction degree of 70-95% of the lump ore reduced by the shaft furnace is added through the screw feeder 11 Separation of the final reduced slag and iron 15 in the melting and gasifier to obtain qualified molten iron whose quality is comparable to that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com