Adjustable potatoes harvester

A potato harvester technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of large volume, high cost of use, and structural fatigue damage of the machine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

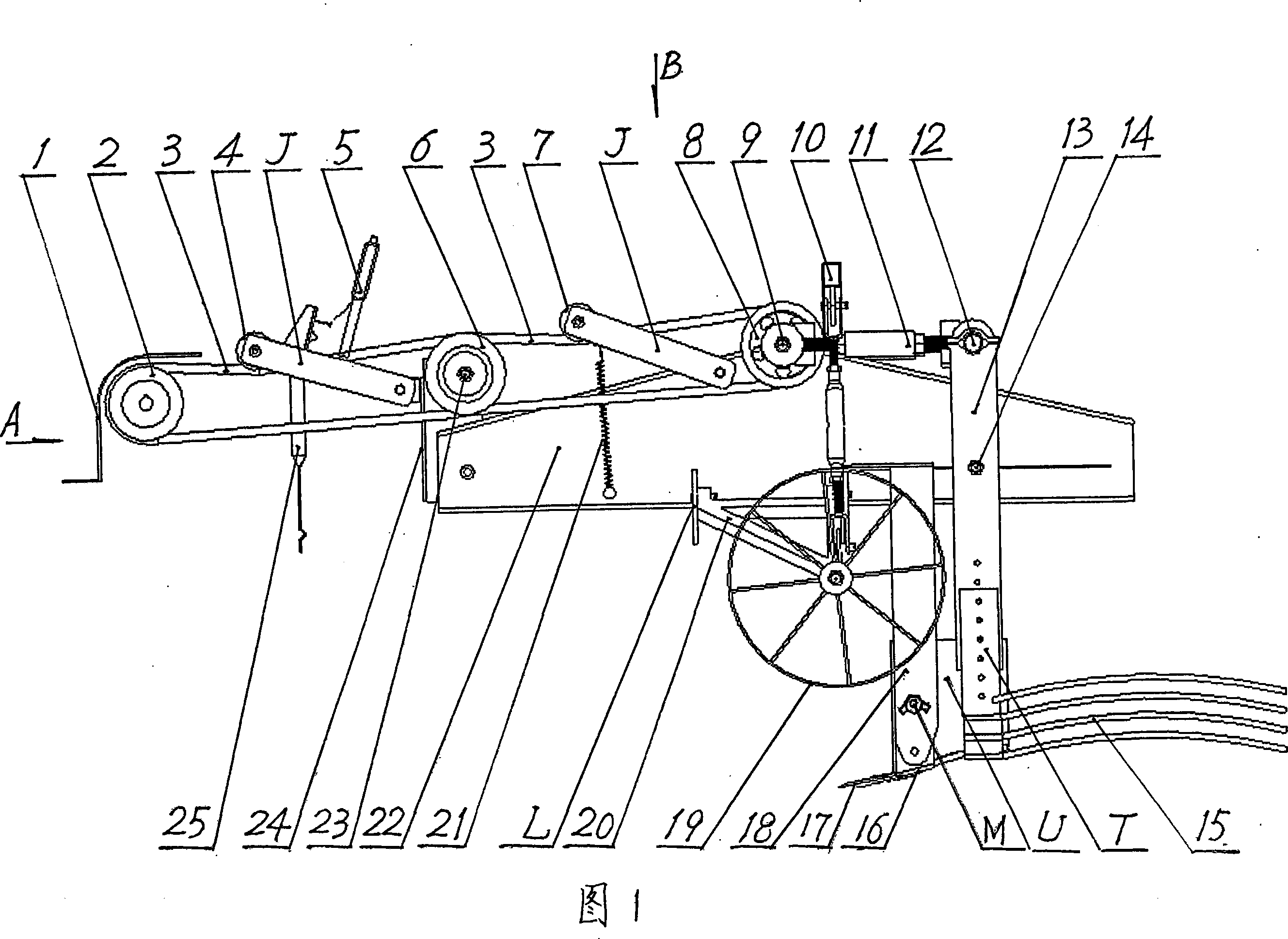

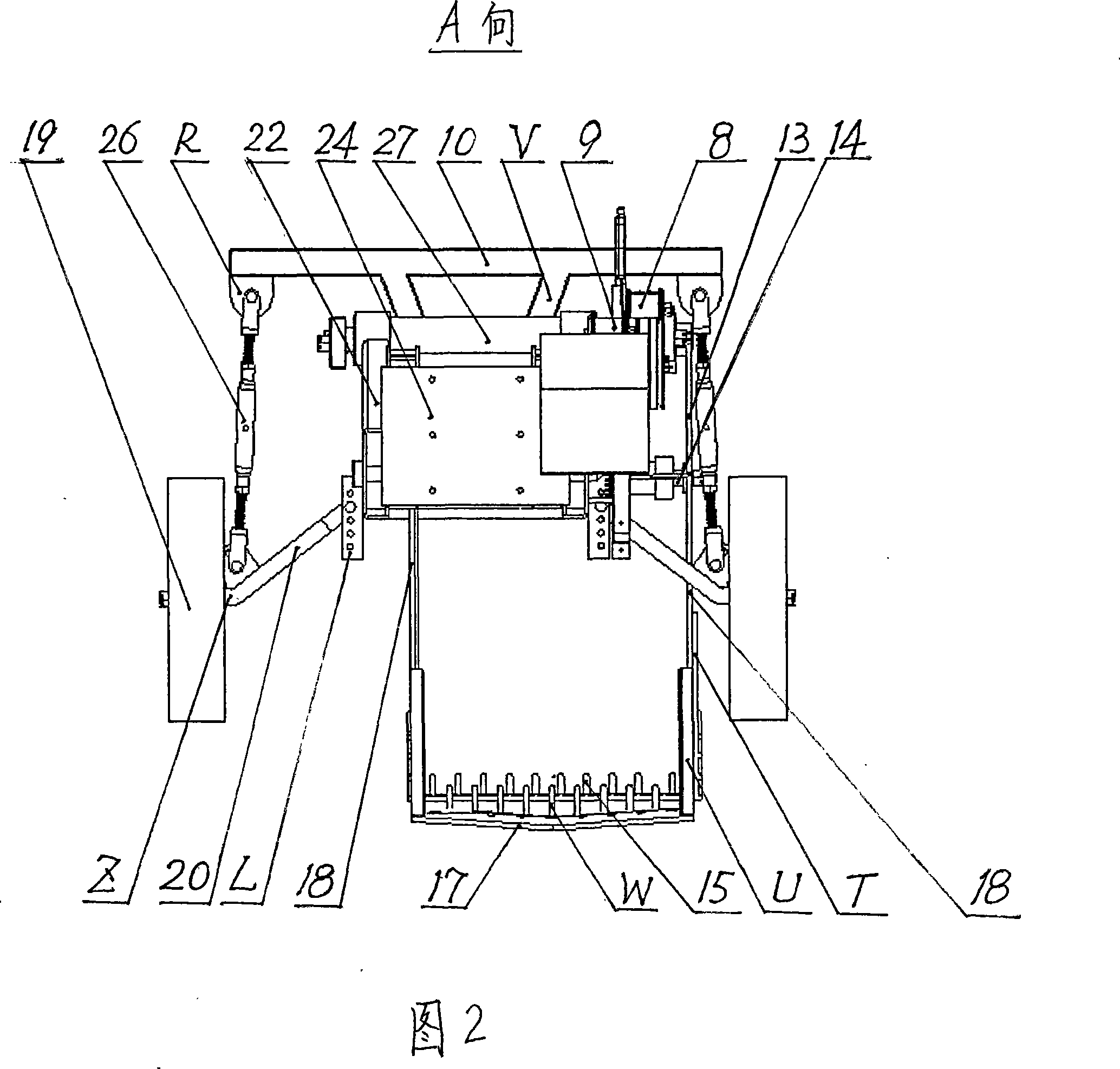

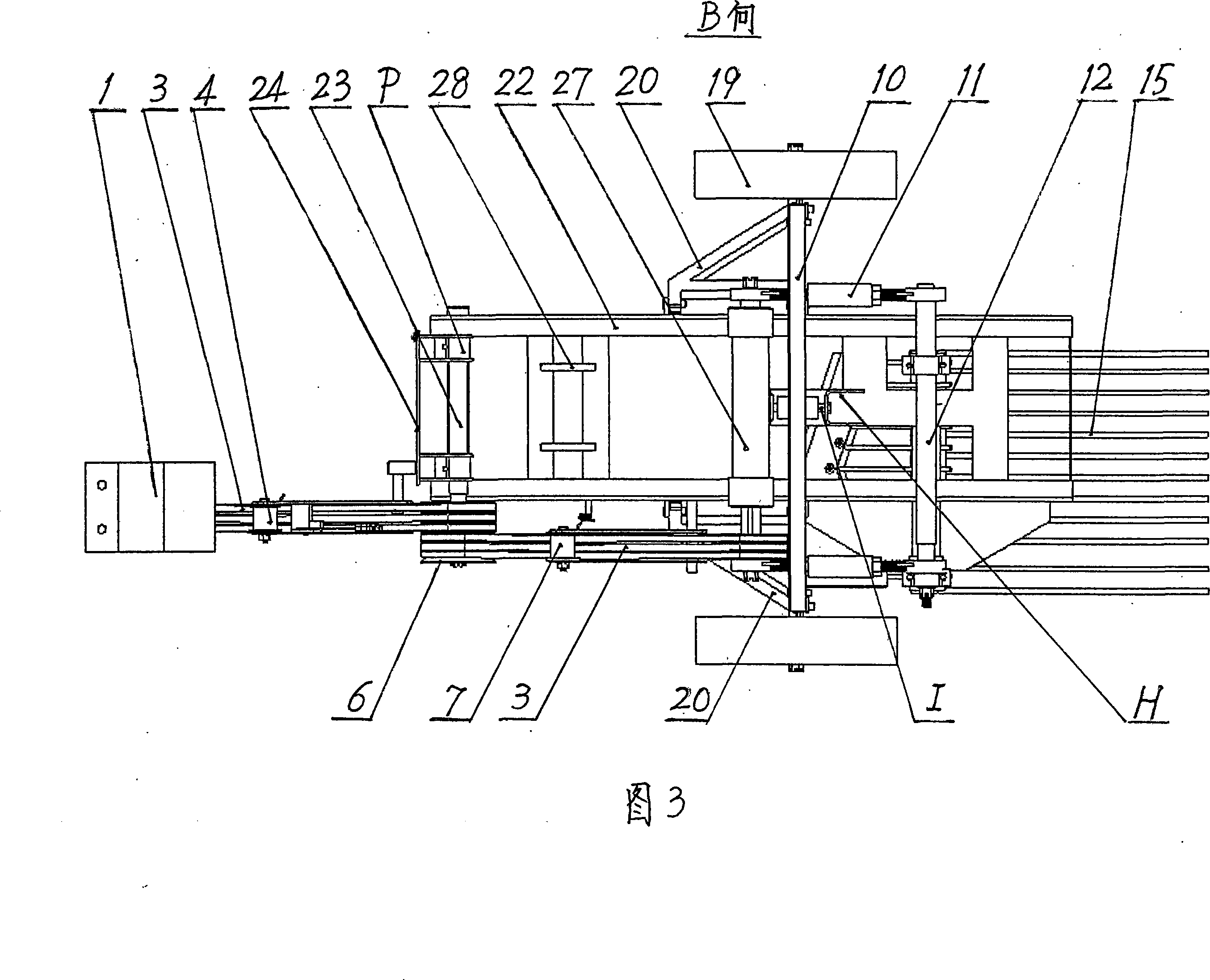

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Referring to Fig. 1, the machine body 22 with the traction frame 24 is connected and fixed with the depth-limiting wheel axle frame 20 installed on the depth-limiting wheel 19 through the connecting plate L, and the lifting lug R of the depth-limiting wheel top beam 10 is connected to the depth-limiting wheel adjusting rod 26 through the depth-limiting wheel adjusting rod 26. The lifting lug R of the depth-limiting wheel axle frame 20 is connected to form a rack device; the power output wheel 2 has a protective cover 1 outside, the bridge pulley 6 is set on the axle end of the bridge wheel shaft 23, and the eccentric shaft pulley 8 is set on the eccentric shaft 9 shaft ends, the bridge wheel shaft 23 is erected in the bridge wheel shaft seat P above the vertical baffle plate N on both sides of the front part of the body 22, the eccentric shaft 9 is installed in the ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com