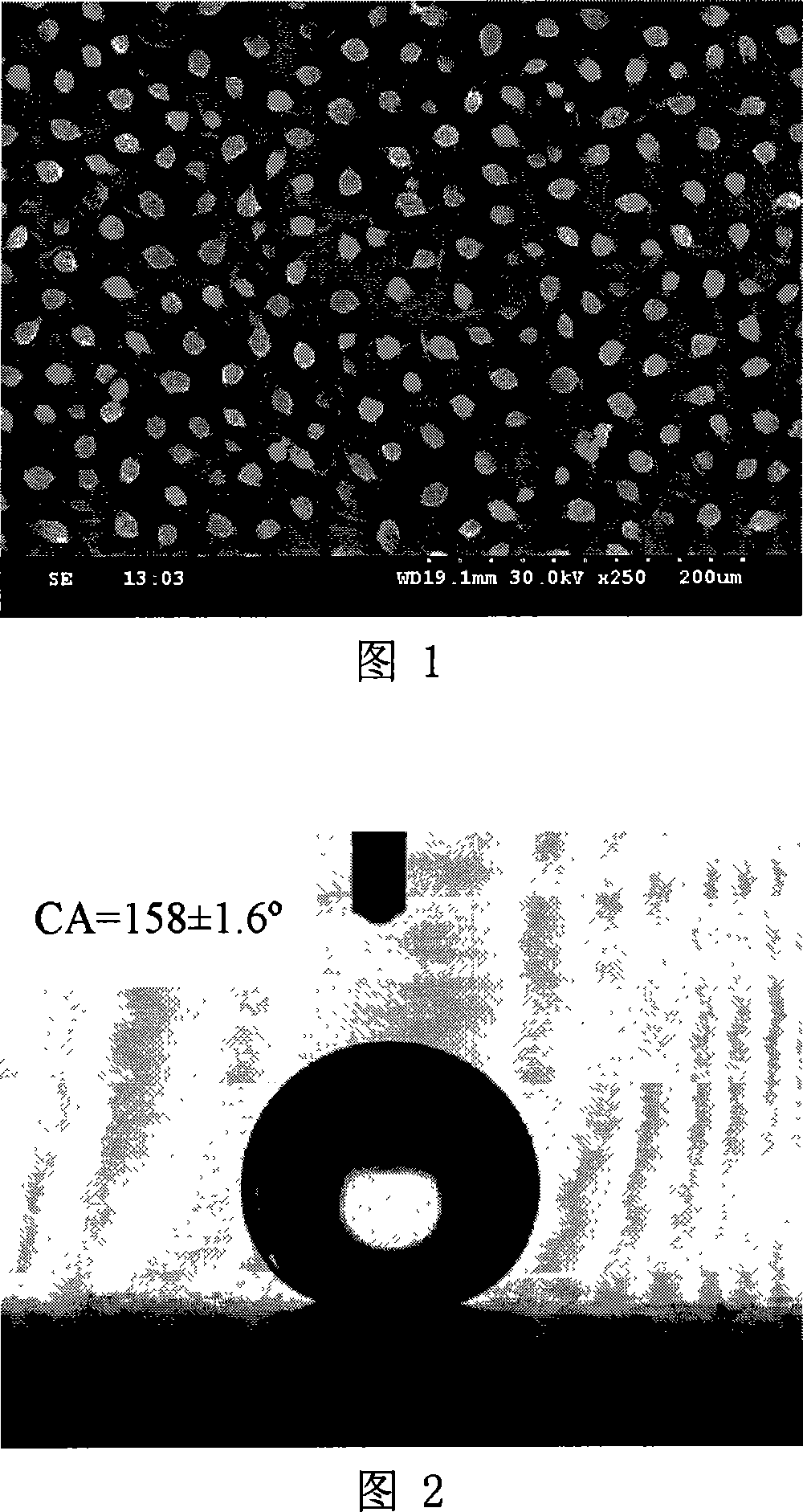

Super-hydrophobic polystyrene film and preparation method thereof

A polystyrene film and super-hydrophobic technology, which is applied in the field of preparing super-hydrophobic polystyrene films, can solve the problems of difficult popularization and application, expensive materials, etc., and achieves the effects of wide application prospects, stable super-hydrophobic properties, and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Rinse the dust on the surface of fresh taro leaves with tap water, then cut the taro leaves into a size of 15 cm and a width of 10 cm, and put them into a casting mold with a height of 5 cm for use;

[0022] The second step: the polydimethylsiloxane (PDMS) prepolymer and its catalyst benzoyl peroxide and the crosslinking agent azobisisobutyronitrile are mixed in a mass ratio of 100:1:5 and stirred for 5 Minutes, then placed in a vacuum box to extract the air bubbles in the mixture, then poured PDMS on the fresh taro leaves in the mold and cured in room temperature and atmospheric environment for 24 hours, then gently tore off the PDMS from the taro leaves to obtain PDMS soft template;

[0023] The third step: place the polydimethylsiloxane (PDMS) soft template in a mold with a height of 5.1 cm, and pour the polystyrene-tetrahydrofuran solution with a concentration of 20 mg / ml into the polydimethylsiloxane ( PDMS) template, and gently tear off the polystyrene fi...

Embodiment 2

[0025] Step 1: Rinse the dust on the surface of fresh taro leaves with tap water, then cut the taro leaves into a size of 15 cm and a width of 10 cm, and put them into a casting mold with a height of 5 cm for use;

[0026] The second step: the polydimethylsiloxane (PDMS) prepolymer and its catalyst benzoyl peroxide and the crosslinking agent azobisisobutyronitrile are mixed in a mass ratio of 100:0.1:10 and stirred for 10 Minutes, then placed in a vacuum box to extract the air bubbles in the mixture, then poured PDMS on the fresh taro leaves in the mold and cured in room temperature and atmospheric environment for 18 hours, then gently tore off the PDMS from the taro leaves to obtain PDMS soft template;

[0027] The third step: place the polydimethylsiloxane (PDMS) soft template in a mold with a height of 5.1 cm, and pour the polystyrene-tetrahydrofuran solution with a concentration of 1 mg / ml into the polydimethylsiloxane ( PDMS) template, and gently tear off the polystyrene...

Embodiment 3

[0029] Step 1: Rinse the dust on the surface of fresh taro leaves with tap water, then cut the taro leaves into a size of 15 cm and a width of 10 cm, and put them into a casting mold with a height of 5 cm for use;

[0030] The second step: the polydimethylsiloxane (PDMS) prepolymer and its catalyst benzoyl peroxide and the crosslinking agent azobisisobutyronitrile are mixed and stirred for 8 Minutes, then placed in a vacuum box to extract the air bubbles in the mixture, then poured PDMS on the fresh taro leaves in the mold and cured in room temperature atmosphere for 30 hours, then gently tore off the PDMS from the taro leaves to obtain PDMS soft template;

[0031] The third step: place the polydimethylsiloxane (PDMS) soft template in a mold with a height of 5.1 cm, and pour the polystyrene-tetrahydrofuran solution with a concentration of 70 mg / ml into the polydimethylsiloxane ( PDMS) template, and gently tear off the polystyrene film after drying in room temperature atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com