Method for preparing monocrystalline germanium nano thread by solvent hot decomposition process

A decomposition method and single-crystal germanium technology, applied in the direction of single-crystal growth, single-crystal growth, chemical instruments and methods, etc., can solve the problems of demanding preparation process, high cost, complicated preparation process, etc., and achieve simple preparation method and low cost Low, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

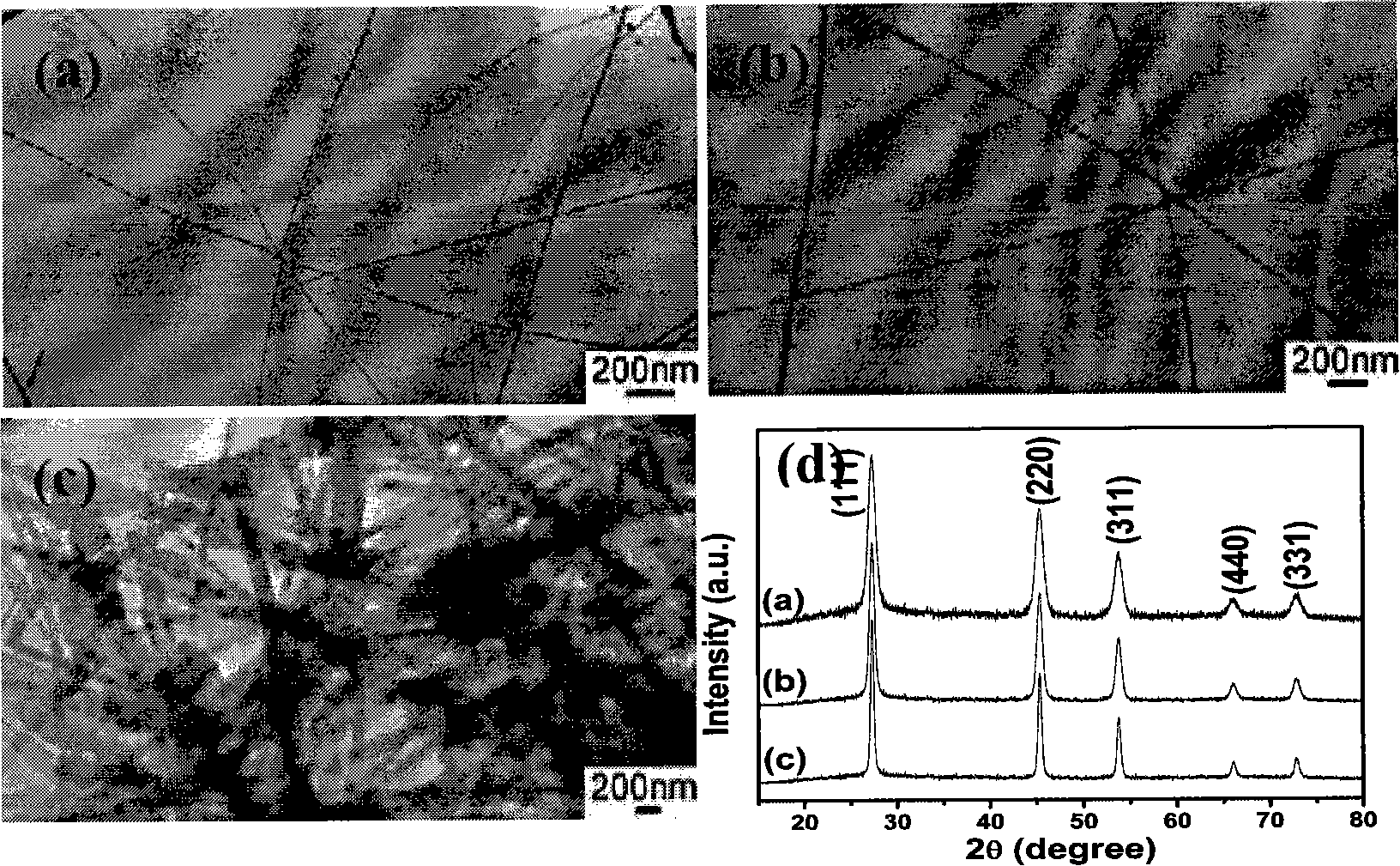

[0023] GeCl 4 Reaction with oleylamine at a ratio of 1:4 yielded light yellow precursor oleylamine germanium TOG: [(CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 CH 2 NH 2 ) 4 Ge] 4+ ·(Cl - ) 4 ; At the same time, take 8ml of trioctylamine and add it to the three-necked flask and heat it to 200°C. At this time, take TOG 9*10 -4 mol was added to the flask, and the temperature was raised to 360°C at a rate of 1°C / min, and reacted for 4 hours. After the reaction, the solution was centrifuged at a centrifugal speed of 10000r / min for 20min. The obtained solid was dispersed with 20 ml of ethanol and ultrasonically washed, centrifuged again, and repeated twice, and the product was dried at room temperature. The transmission electron microscope photo of the product can be found in figure 1 (a), TOG is 9*10 -4 mol, wire diameter 20nm. figure 2 yes figure 1 (a) Morphology and characterization of germanium nanowires:

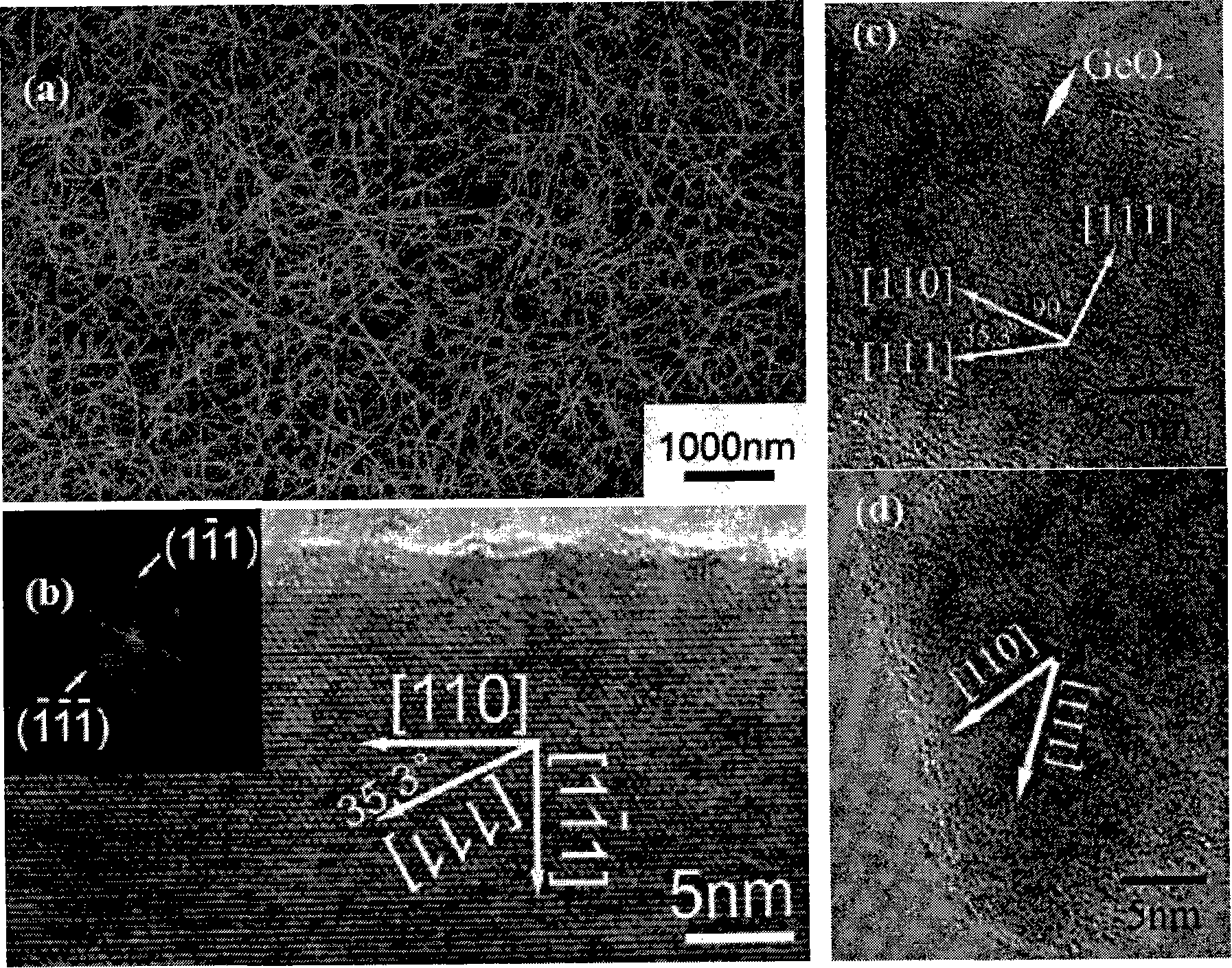

[0024] (a) SEM photo of a germanium nanowire; (b) high-resolution TE...

Embodiment 2

[0026] GeCl 4 Reaction with oleylamine at a ratio of 1:5 yielded light yellow precursor oleylamine germanium TOG: [(CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 CH 2 NH 2 ) 4 Ge] 4+ ·(Cl - ) 4 ; At the same time, take 8ml of trioctylamine and add it to the three-necked flask and heat it to 200°C. At this time, take TOG 1.8*10 -3 mol was added to the flask, and the temperature was raised to 360°C at a rate of 1°C / min, and reacted for 4 hours. After the reaction, the solution was centrifuged at a centrifugal speed of 10000r / min for 20min. The obtained solid was dispersed with 20 ml of ethanol, washed with ultrasonic waves, centrifuged again, and repeated twice, and the product was kept at room temperature. The transmission electron microscope photo of the product can be found in figure 1 (b), TOG is 1.8*10 -4 mol, wire diameter 47nm.

Embodiment 3

[0028] GeCl 4 Reaction with oleylamine at a ratio of 1:6 yielded light yellow precursor oleylamine germanium TOG: [(CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 CH 2 NH 2 ) 4 Ge] 4+ ·(Cl - ) 4 ; At the same time, take 8ml of trioctylamine and add it to the three-necked flask and heat it to 200°C. At this time, take TOG 2.7*10 -3 mol was added to the flask, and the temperature was raised to 360°C at a rate of 1°C / min, and reacted for 4 hours. After the reaction, the solution was centrifuged at a centrifugal speed of 10000r / min for 20min. The obtained solid was dispersed with 20 ml of ethanol and ultrasonically washed, centrifuged again, and repeated twice, and the product was dried at room temperature. The transmission electron microscope photo of the product can be found in figure 1 (c), TOG is 2.7*10 -4 mol, wire diameter 115nm.

[0029] figure 1 (d) XRD patterns corresponding to the samples of the above three examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com