Electronic accelerator

A technology of electron accelerators and capacitor plates, applied in the direction of DC voltage accelerators, electrical components, accelerators, etc., can solve the problems of distance reduction, inability to meet strong currents, etc., and achieve the effect of reducing operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

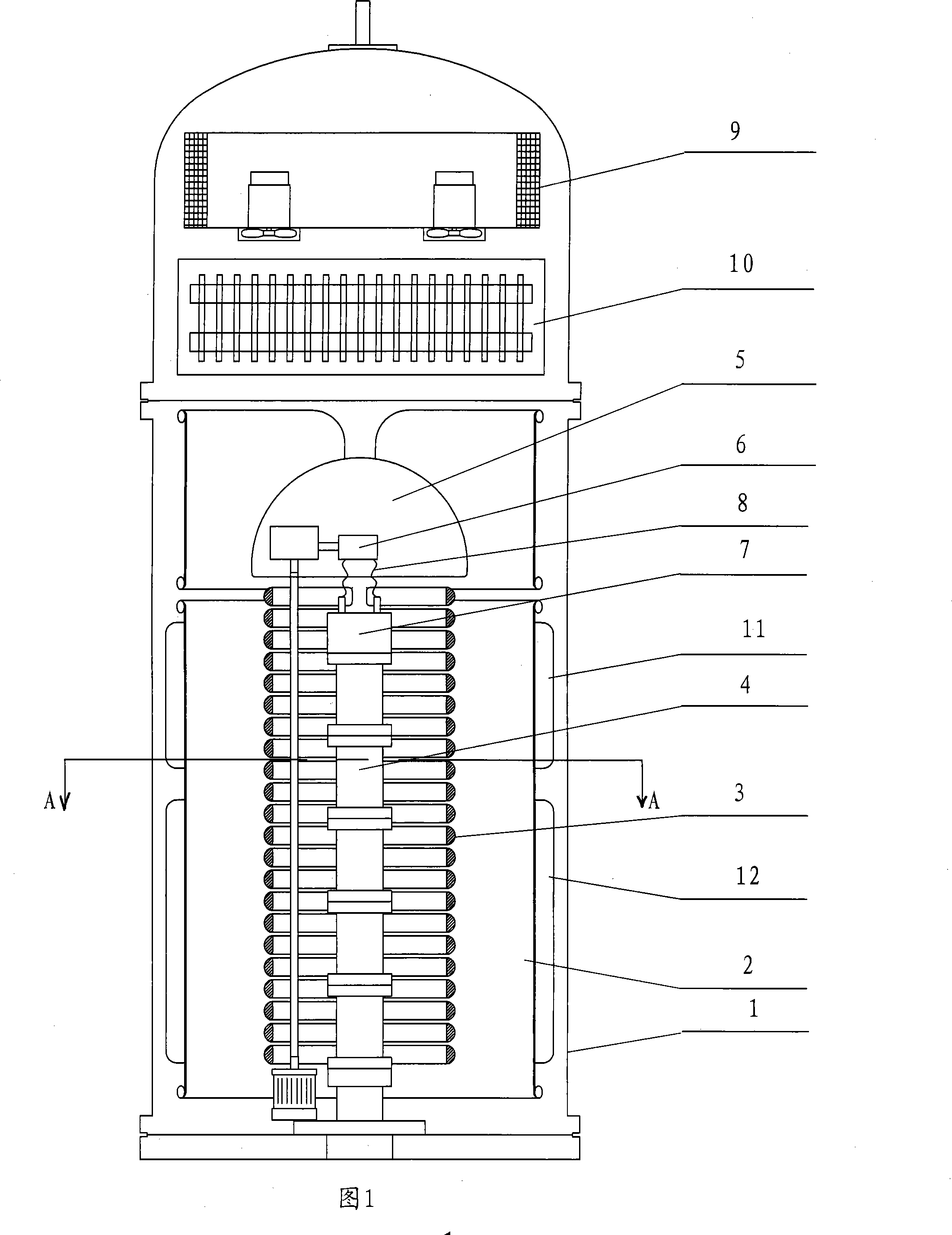

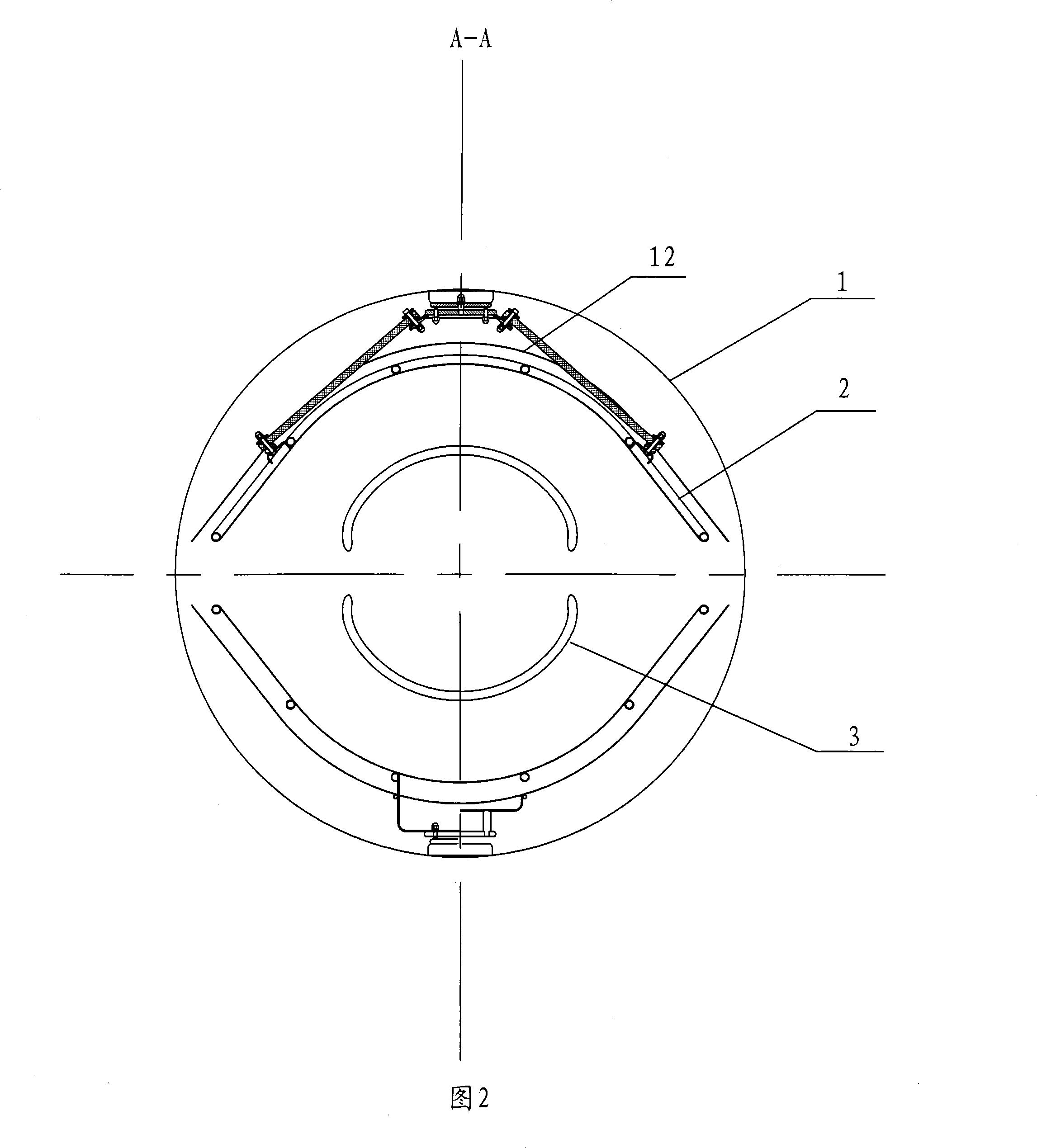

[0015] The electron accelerator shown in Figure 1 includes a steel cylinder 1, a cold trap 9 arranged above the steel cylinder 1, a high-frequency transformer 10 arranged below the cold trap 9, and a plurality of semicircular electrodes arranged inside the steel cylinder 1. Halo ring 3, a high-voltage electrode 5 arranged above the corona ring 3, two high-frequency electrodes 2 arranged outside the corona ring 3 and the high-voltage electrode 5, an electron gun 7 with a filament 8 for generating and exciting electrons, The filament transformer 6 connected with the filament 8, the vacuum accelerating tube 4 arranged under the electron gun 7, the control system arranged outside the steel cylinder 1, and the high-frequency oscillator arranged outside the steel cylinder 1 for supplying power to the electron accelerator The device, the feedback capacitance plate 11 is arranged between the steel cylinder 1 and the high-frequency electrode 1, and a plurality of semicircular corona rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com