Power LED with glue-filling formed bottom and manufacturing method thereof

A technology of LED chips and lenses, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of restricting the development of such products, low production efficiency, etc., to meet the requirements of reflow soldering conditions, high product reliability, and increase adhesion the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The concrete implementation examples of the present invention are described as follows:

[0027] 1. Lens forming mold preparation:

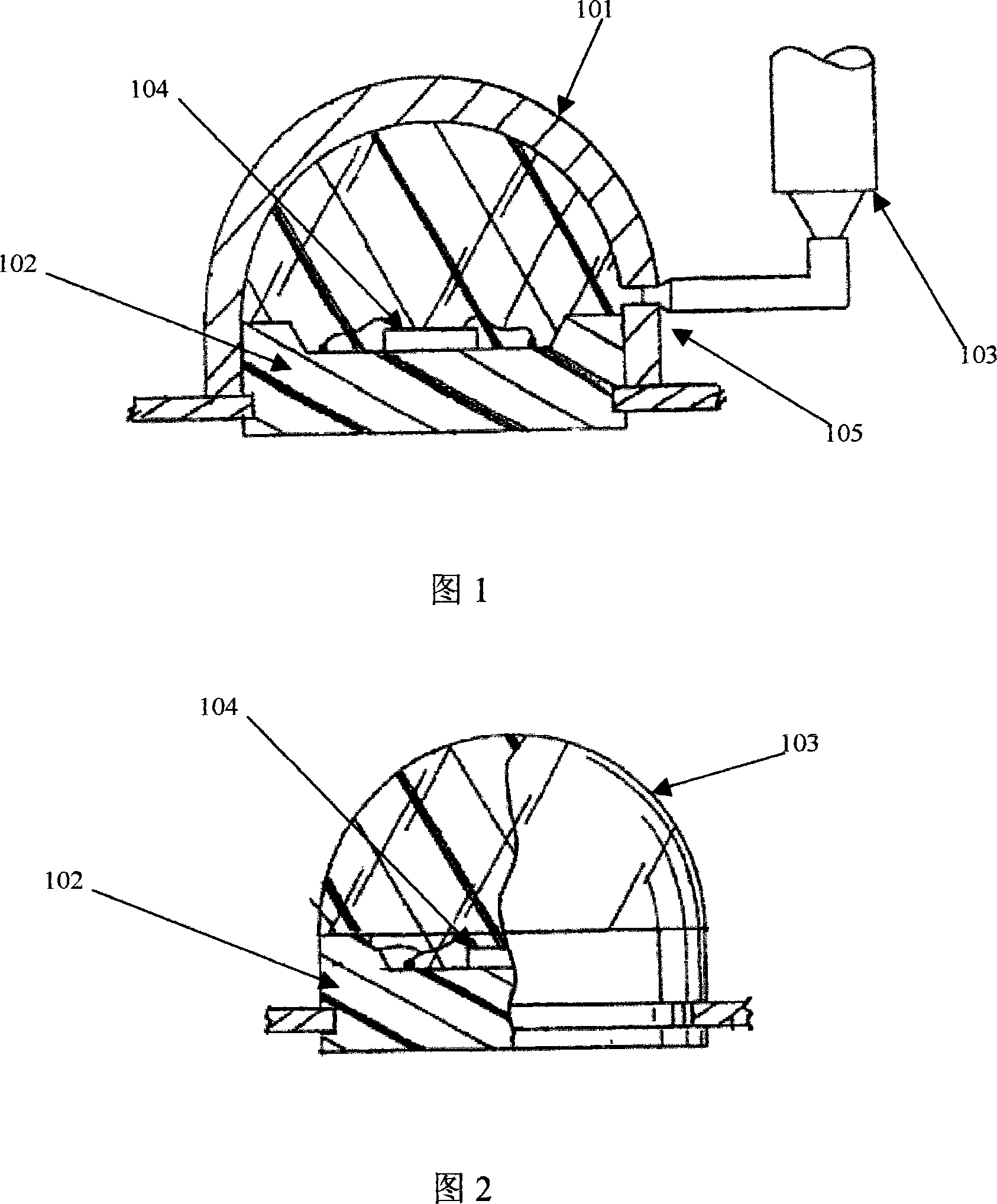

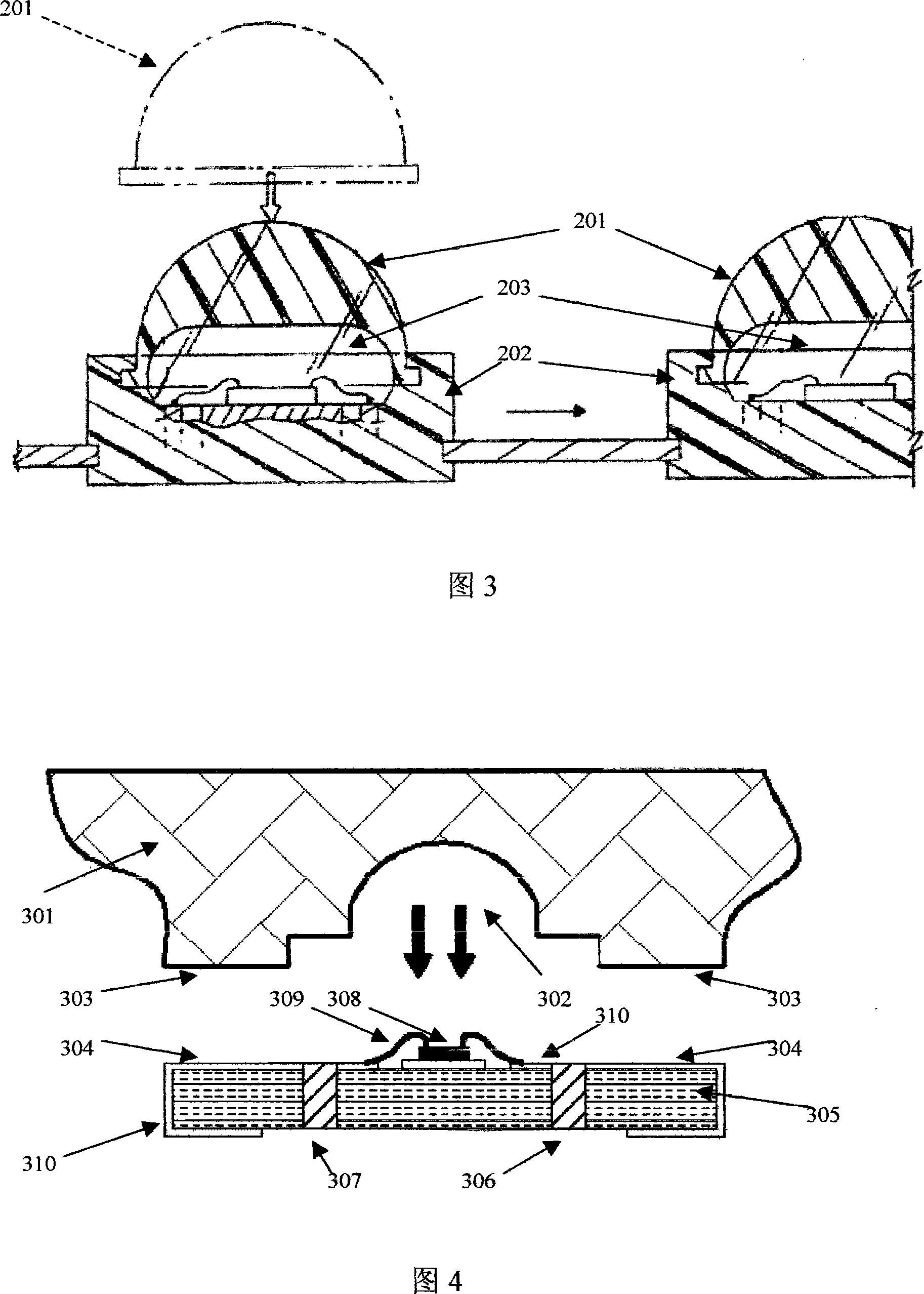

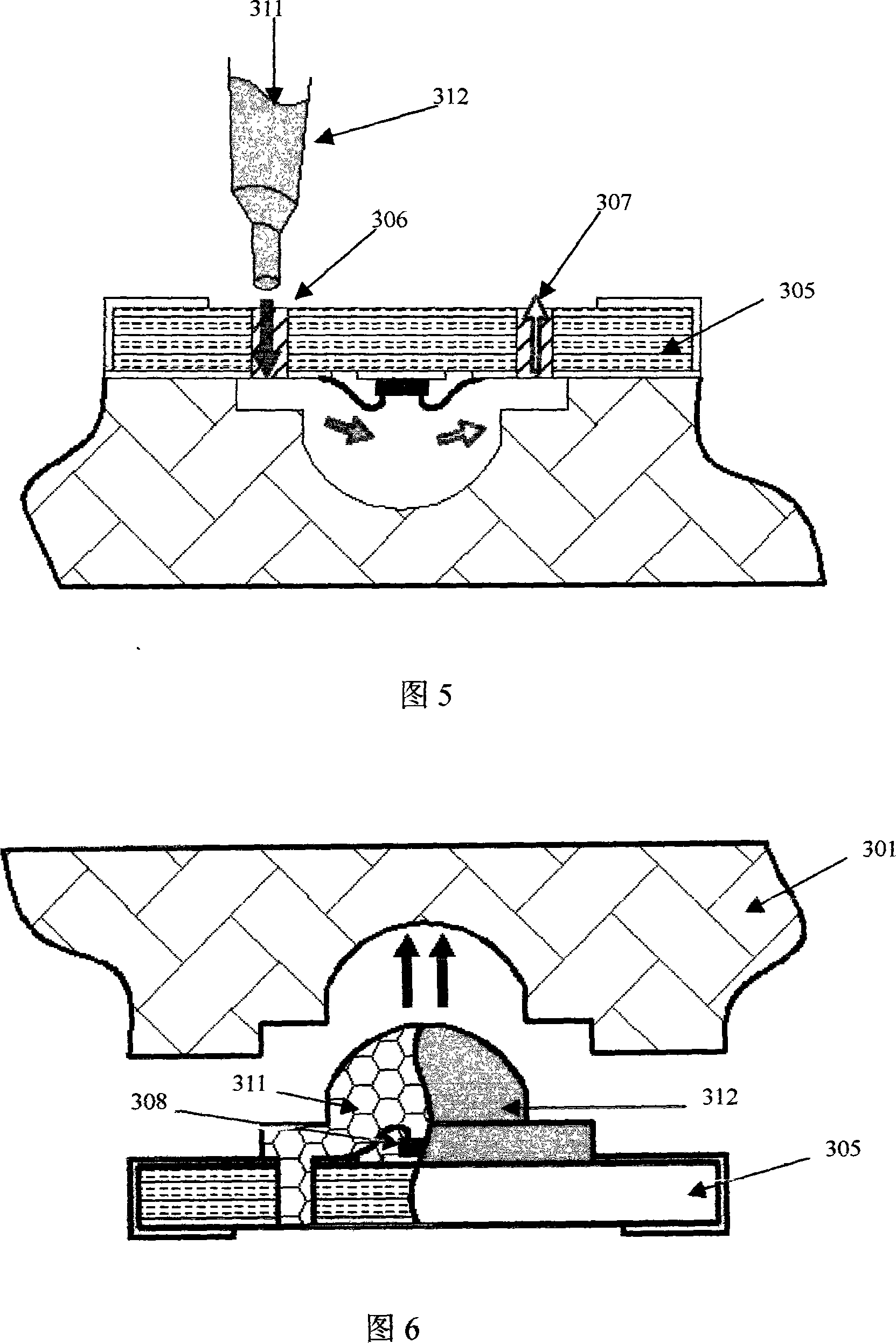

[0028] As shown in FIG. 4 , a cavity 302 conforming to the lens shape is prepared on one side of the material of the mold 301 , and the surroundings of the cavity 302 are kept flat to ensure sufficient contact between the contact surfaces 303 and 304 between the mold 301 and the substrate 305 .

[0029] 2. Substrate preparation:

[0030] The glue injection hole 306 and the exhaust hole 307 are processed on the substrate 305 by hole processing technology, as shown in FIG. 4 , the processing position is below the lens position, and the number is one each. The LED chip 308 is placed on the substrate 305 , and the electrode of the LED chip 308 is electrically connected to the lead electrode 310 on the substrate 305 by using the lead wire 309 through an ultrasonic welding process.

[0031] 3. Lamination of lens mold and substrate:

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com