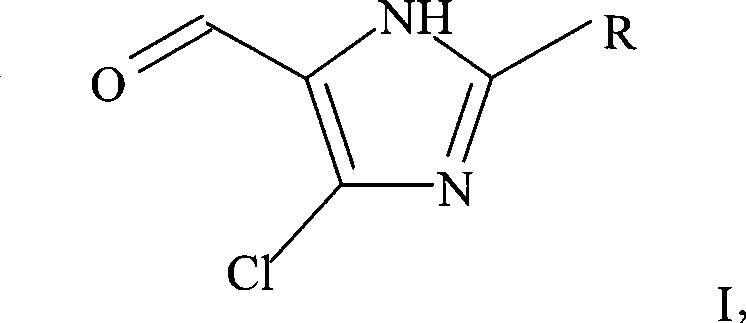

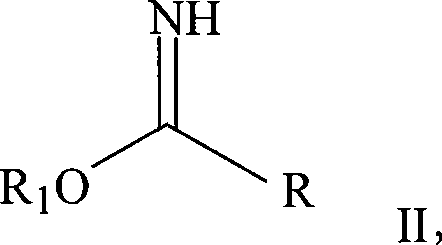

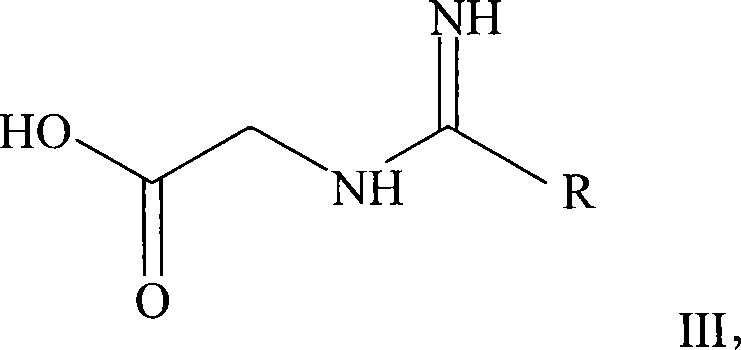

Preparation of 2-substituted 4-chloro-5-formylimidazoles by vilsmeier reaction of the condensation product of glycine and an imido ester with a formamide in the presence of a triflate (trifluormethane

A kind of formyl imidazole, imidate technology, is applied in 2-butyl-5-formyl imidazole, 2-butyl-4-chloro-5-formyl imidazole, prepares 2-substituted 4-chloro- 5-formyl imidazole, the field of preparing 2-substituted-5-formyl imidazole, can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 - Preparation of methyl pentanimidate from valeronitrile

[0051] 100 g (1.20 mol) of valeronitrile was added to 58 ml of methanol and cooled to -5 to -10°C. HCl gas was slowly bubbled through the solution for 15-18 hours. At a temperature of 0-15°C, use 1.5 to 2.0kg / cm 2 Nitrogen pressure for 14 hours, followed by the addition of 55 ml of methanol and stirring for a further 60 minutes.

[0052] The reactant was then transferred into methanolic ammonia solution (12-15 wt%) and stirred at 20-30°C for 3 hours while maintaining the pH at 8-9. The precipitate was then filtered and washed with 25 ml of methanol. The filtrate was concentrated by distilling under reduced pressure (650-700 mm Hg) to completely remove the methanol at a temperature not exceeding 90°C. The semisolid intermediate (methyl pentaminate) was obtained after cooling with a purity of 95% and a yield of 140 g (1.15 mol; 96%).

Embodiment 2

[0061] Example 2 - Preparation of BCFI from methyl pentanimidate using trifluoromethanesulfonic acid catalyst

[0062] At 0° C., 50 g (0.666 mol) of glycine was added to a freshly prepared methanolic sodium hydroxide solution (26.64 g (0.666 mol) of sodium hydroxide in 250 ml of methanol) and stirred for another 15 minutes. 80 g (0.70 mol) of methyl pentaminate prepared according to Example 1 were added to the above suspension at 0-5° C. over a period of 10-15 minutes and stirring was continued at room temperature for 16 hours . The solvent was then vacuum distilled at a temperature below 50°C.

[0063] 500 ml of toluene was added to the above reaction mass, followed by the addition of 0.25 g of copper(II) triflate. Then, 320 g (2.08 mol) of phosphorus oxychloride were added to the reaction mixture within 60 minutes, followed by 150 g (2.05 mol) of N,N-dimethylformamide within 2 hours. The reaction mixture was heated to 100°C and stirred for 2 hours, then cooled to 30°C a...

Embodiment 3

[0069] Example 3 - Preparation of BFI by BCFI

[0070] In a pressure cooker, 50 g (0.27 mol) of 2-butyl-4-chloro-5-formyl imidazole was added in 500 ml of methanol and 32 g of triethylamine was added, followed by 2.5 g of carbon containing 10% palladium . Keep the pressure of hydrogen in the pressure cooker at 4-5kg / cm2 at a temperature of 20-25°C 2 Up to 8-10 hours while monitoring the reaction by thin layer chromatography.

[0071] At the end of the reaction, the reaction mixture was poured out of the autoclave and the solvent was removed under reduced pressure at a temperature below 50°C. 250ml of deionized water was added to the dry mixture and cooled to 25-30°C. The pH was readjusted to 1.2 using diluted hydrochloric acid. The aqueous layer was then washed with 50 ml of dichloromethane to remove traces of starting material. Then, the pH was readjusted to 6.8-7.5 using sodium carbonate solution, and the aqueous layer was extracted with 3 x 150 ml dichloromethane. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com