Liquid-cooling heat radiator

A cooling device and liquid cooling technology, applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problems of reducing cooling effect, reducing heat dissipation efficiency, increasing wind resistance, etc., to improve cooling and cooling capacity, increase heat dissipation area, the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

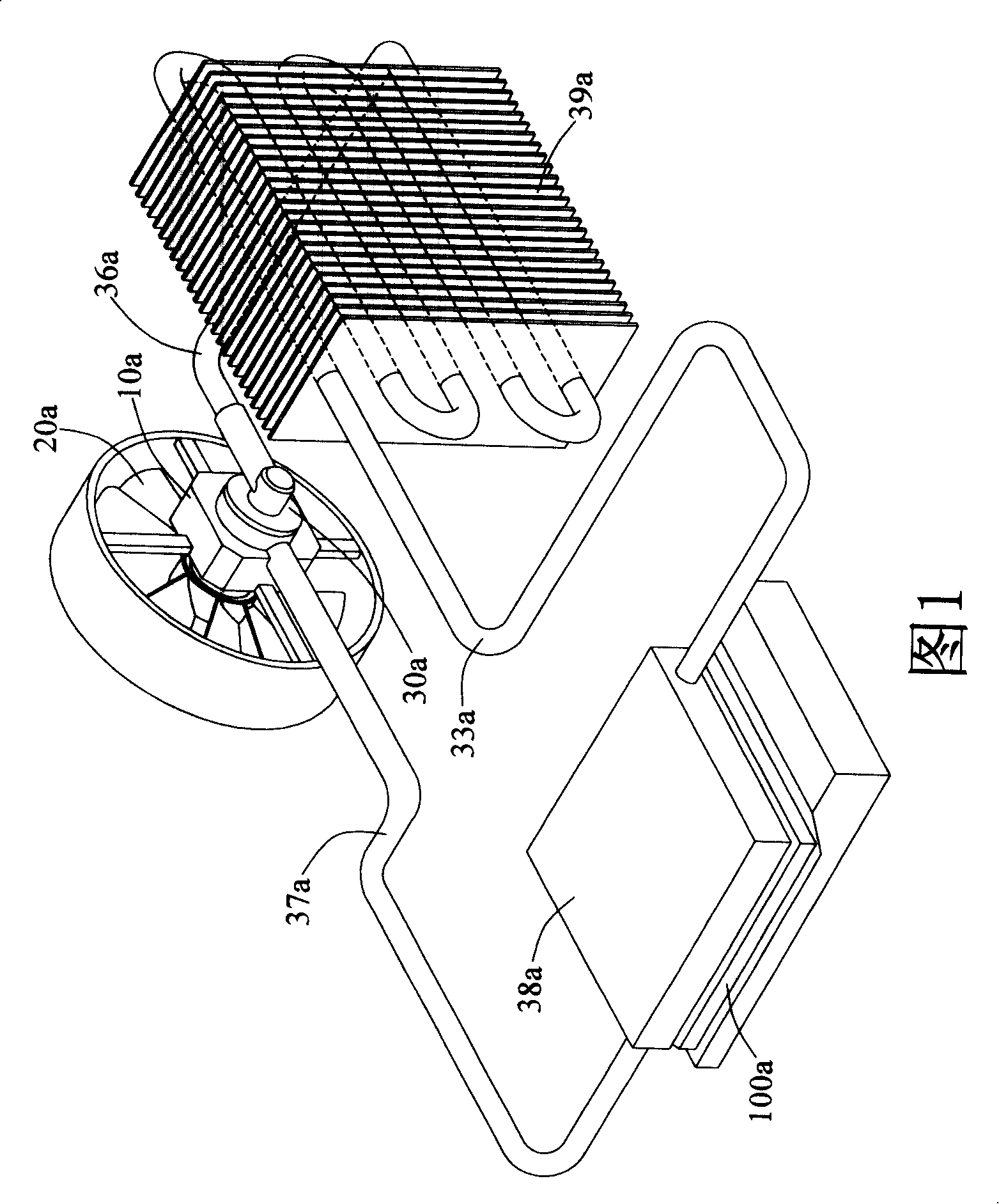

[0068] The liquid-cooled heat dissipation device disclosed in the present invention is applied to heat-generating electronic components, wherein the heat-generating electronic components are central processing unit chips, but are not limited to central processing unit chips, such as integrated circuit chips that can generate heat. In the following specific embodiments of the present invention, the technology disclosed in the invention will use a central processing unit chip as an application embodiment.

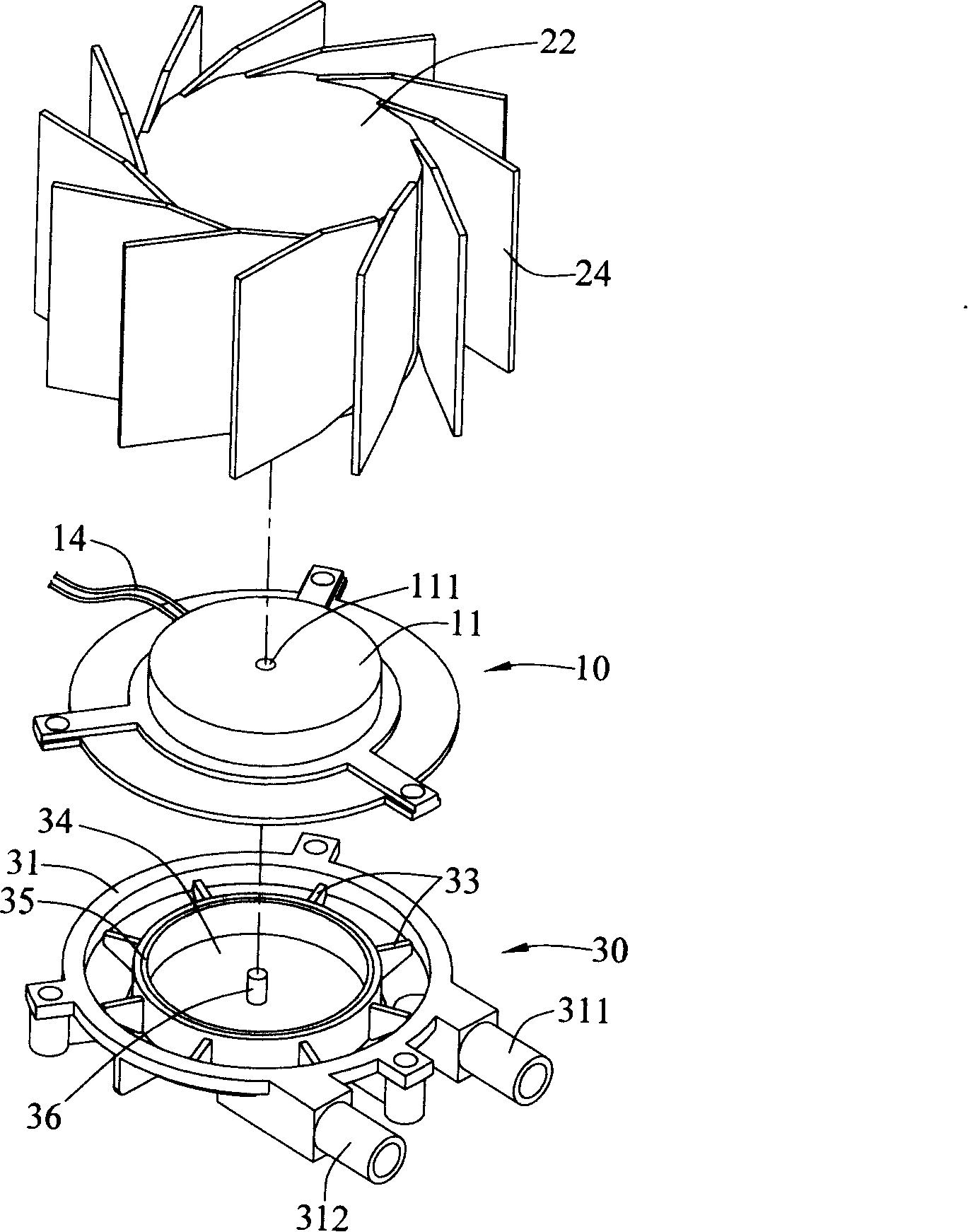

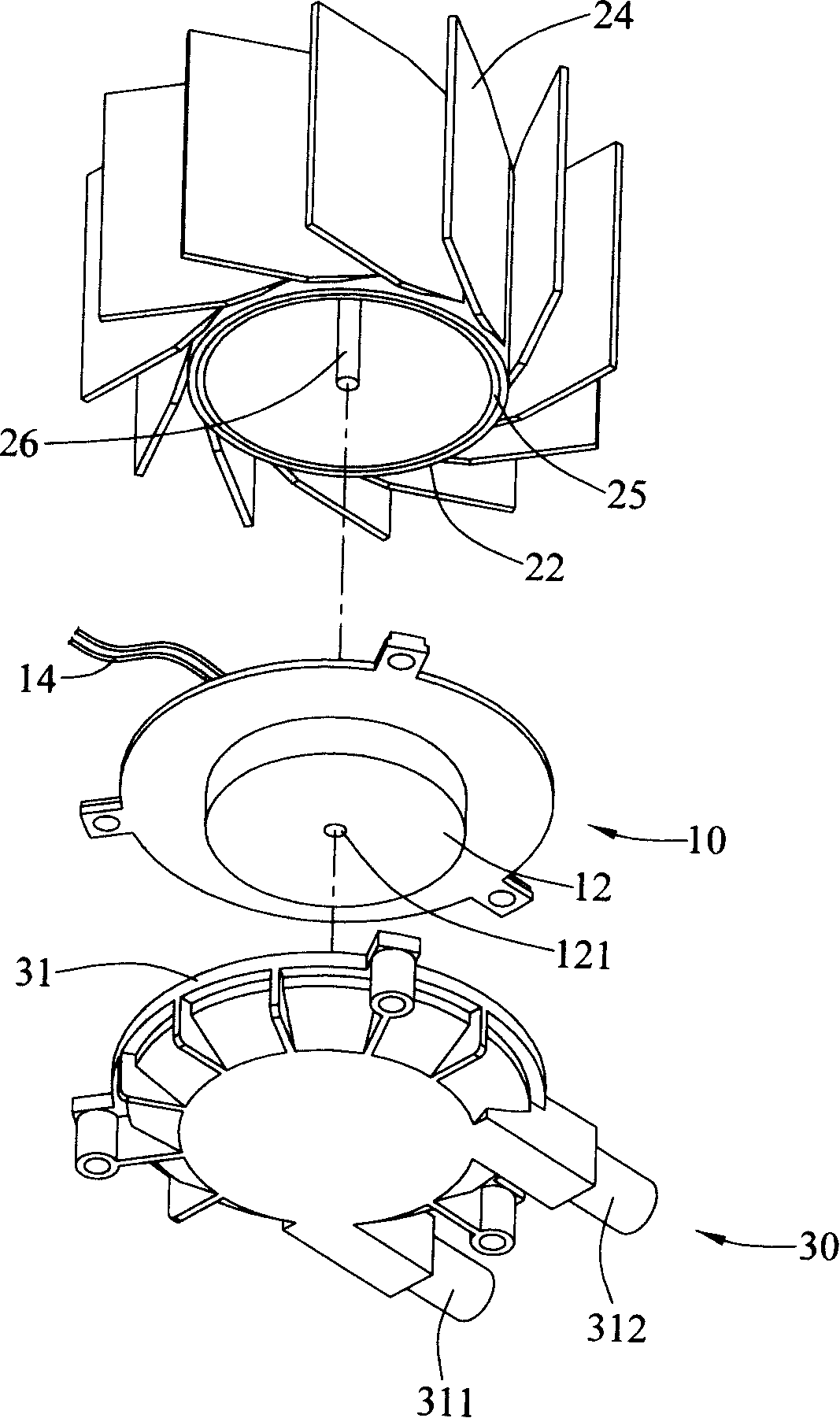

[0069] Please refer to Figure 2A , Figure 2B, and with reference to FIG. 3 , it includes a motor 10, a cooling fan 20, a pump 30 and a liquid pipe 50, wherein the motor 10 and the pump 30 are located in the housing 40, and the housing 40 is provided with two through holes 41, 42, and the motor The first stator 11 and the second stator 12 protrude from the two sides of 10 respectively, and the top side of the first stator 11 and the bottom side of the second stator 12 each h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com