Sea surface microstructure measuring device for ship

A measurement device and microstructure technology, which is applied to measurement devices, uses optical devices to transmit sensing components, and measures inclination and other directions, can solve problems such as light intensity changes, optical path differences, and inability to monitor and observe image quality in real time, and meet the needs of Requirements of precision optical system, good effect of rigid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

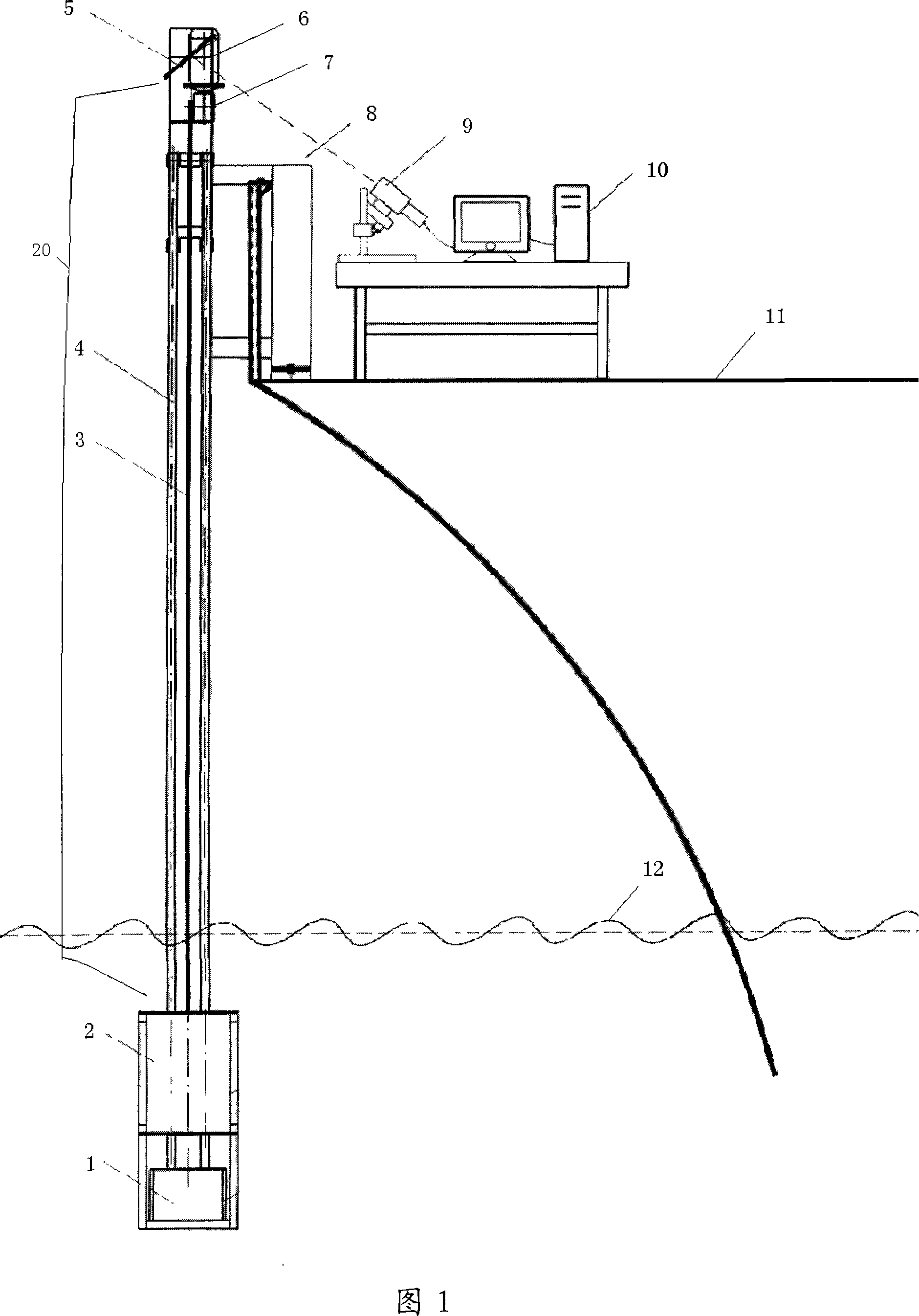

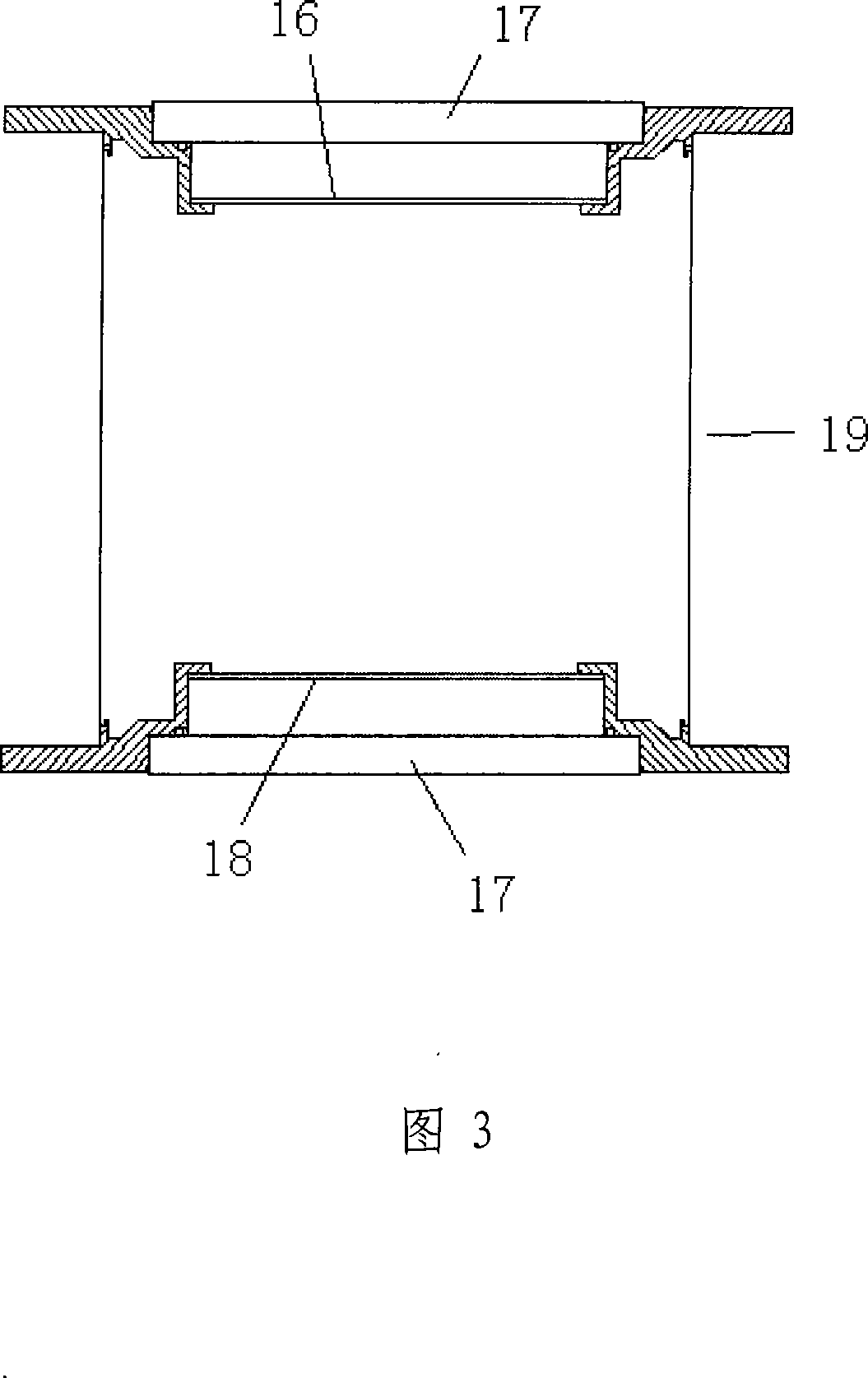

[0015] As shown in Fig. 1, Fig. 3, the present invention comprises the underwater optical device that is made up of light source 1 and measuring encoder 2 and is sealed via optical window glass 17, and the information transmission processing system that is made up of CCD camera 9 and computer 10 is characterized in that It also includes lifts connected to underwater optics.

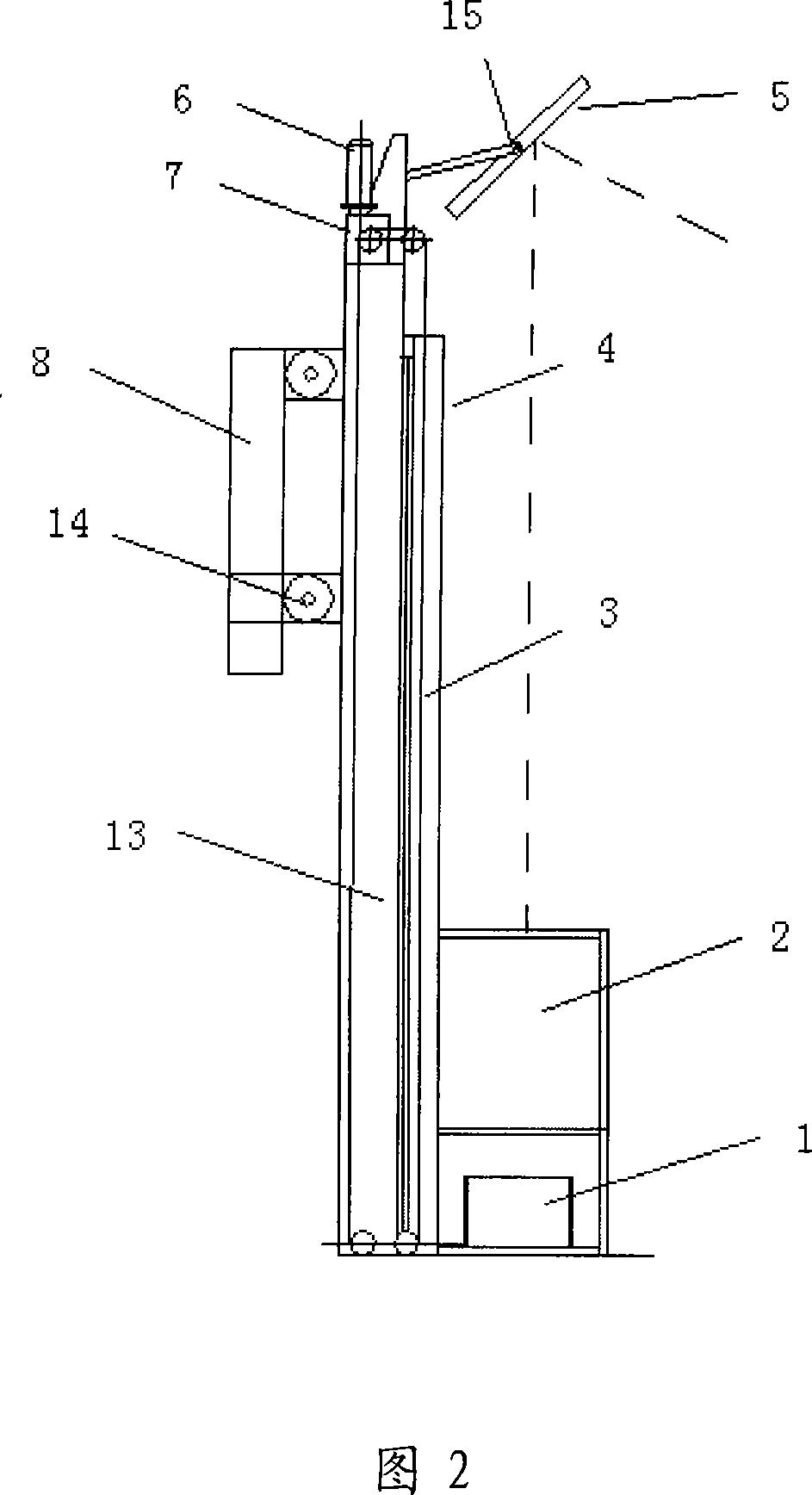

[0016] As shown in Figure 1 and Figure 2, the lifting device is fixed on the base 8 of the ship's side, and the rail frame 13 is connected to the base 8 through two parallel snap rings 14 located at the upper and lower edges of the ship's side baffle, and the snap ring 14 can be opened And locking, respectively corresponding to the retractable and working state of the guide rail frame 13. The base 8 is fixed on the ship deck 11 by means of electric welding. The lifting chain 3 is fixed on the guide rail frame 13, and is pulled and moved by the motor 6. Guide rail 4 is welded on the guide rail frame 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com