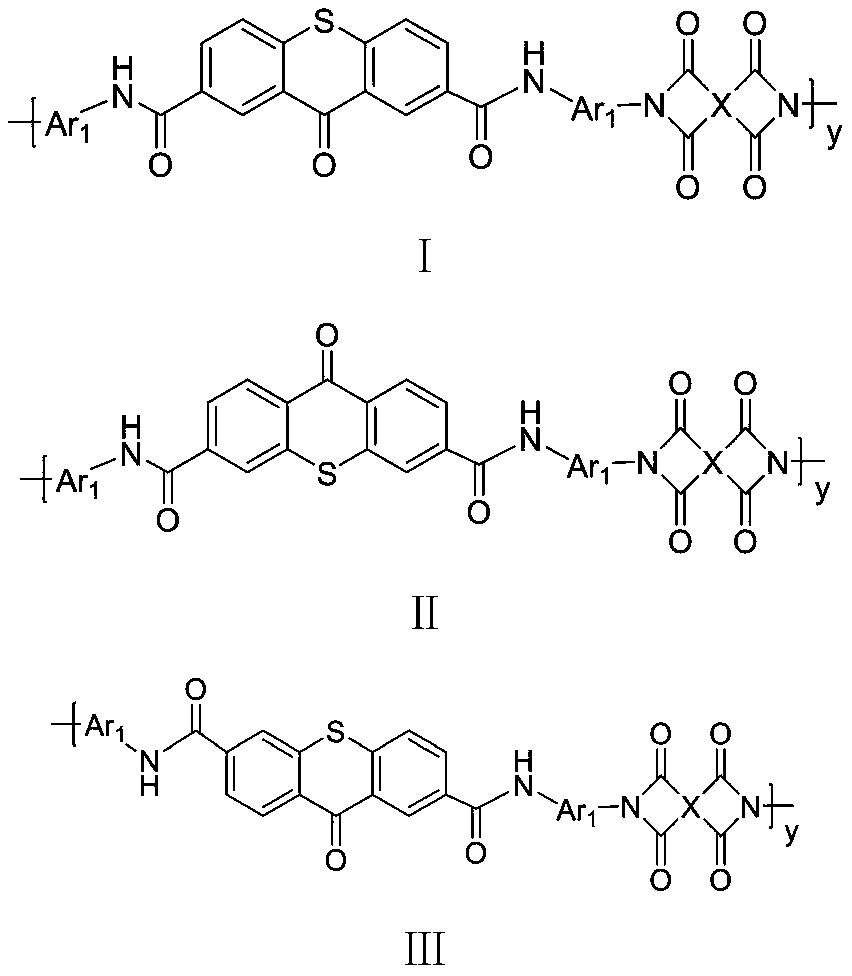

Thioxanthone polyimide with high planar rigidity as well as preparation method and application thereof

A polyimide and thioxanthone technology, which is applied in the field of material science, can solve the problems of poor heat resistance of high-barrier film, influence of flexibility of coating film, easy to break and fall off, etc., and achieve excellent barrier performance and regular molecular chain arrangement. , the effect of high electron density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

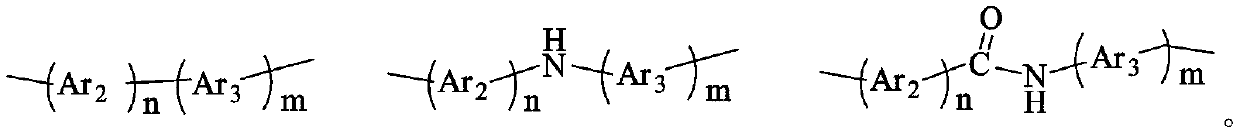

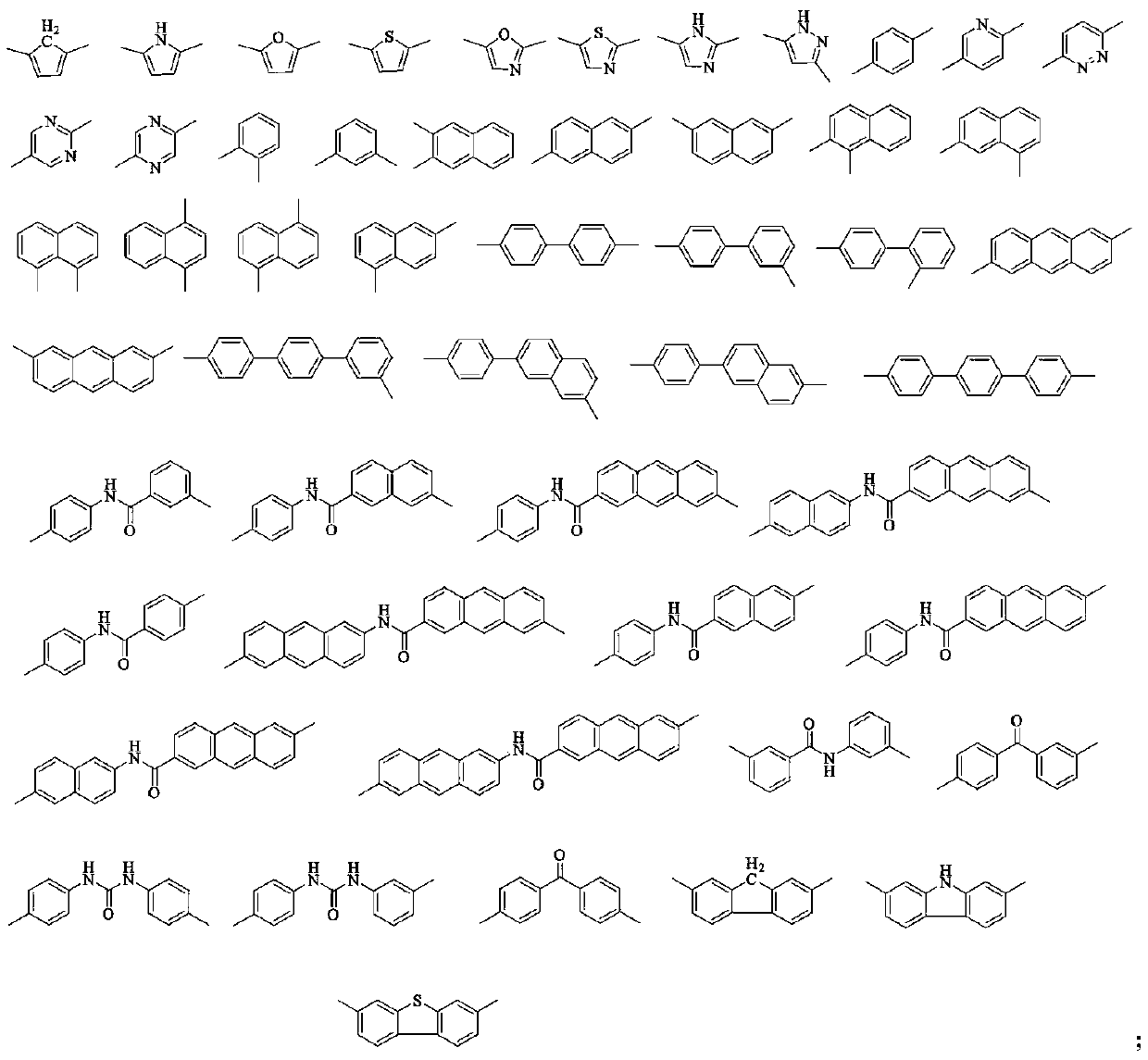

Method used

Image

Examples

Embodiment 1

[0043] This example provides

[0044] Synthesis of N3,N6-bis(4-aminophenyl)-9-oxo-9H-thioxanthene-3,6-dicarboxamide:

[0045]

[0046] S1. Synthesis of intermediate 9-oxo-9H-thioxanthene-3,6-dicarbonitrile:

[0047] Add 3.70g (0.01mol) of 3,6-dibromo-9H-thioxanthen-9-one, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then Will H 2 O (180mL), HCl (60mL) and FeCl3 (4.19g, 25.8mmol) were poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, and the resulting solid was re-dissolved in dichloromethane and washed with water , the solvent was removed under reduced pressure to give the crude product as a brown solid, which was triturated with methanol to afford intermediate one. This intermediate one structure is as follows:

[0048]

[0049] S2. Synthesis of intermediate 9-oxo-9H-thioxanthene-3,6-dicarboxylic acid:...

Embodiment 2

[0061] This example provides

[0062] Synthesis of N2,N6-bis(5-aminothiophen-2-yl)-9-oxo-9H-thioxanthene-2,6-dicarboxamide:

[0063]

[0064] S1. Synthesis of intermediate 9-oxo-9H-thioxanthene-2,6-dicarbonitrile:

[0065] Add 3.70g (0.01mol) of 2,6-dibromo-9H-thioxanthen-9-one, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then Will H 2 O (180mL), HCl (60mL) and FeCl3 (4.19g, 25.8mmol) were poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, and the resulting solid was re-dissolved in dichloromethane and washed with water , the solvent was removed under reduced pressure to give the crude product as a brown solid, which was triturated with methanol to afford intermediate one. This intermediate one structure is as follows:

[0066]

[0067] S2. Synthesis of intermediate 9-oxo-9H-thioxanthene-2,6-dicarboxy...

Embodiment 3

[0079] This example provides a synthetic

[0080] N2,N7-bis(7-aminodibenzo[b,d]furan-3-yl)-9-oxo-9H-thioxanthene-2,7-dicarboxami-de:

[0081]

[0082] S1. Synthesis of intermediate 9-oxo-9H-thioxanthene-2,7-dicarbonitrile:

[0083] Add 3.70g (0.01mol) of 2,7-dibromo-9H-thioxanthen-9-one, 4.478g (0.05mol) of cuprous cyanide, and 50ml of dry NMP into a 500ml three-necked flask, reflux at 140°C for 24h, and then Will H 2 O (180mL), HCl (60mL) and FeCl3 (4.19g, 25.8mmol) were poured into the reaction solution and stirred for 1h, cooled to room temperature, filtered to obtain a brown precipitate, and washed with water, and the resulting solid was re-dissolved in dichloromethane and washed with water , the solvent was removed under reduced pressure to give the crude product as a brown solid, which was triturated with methanol to afford intermediate one. This intermediate one structure is as follows:

[0084]

[0085]S2. Synthesis of intermediate 9-oxo-9H-thioxanthene-2,7-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com