Copper ammonia fiber colored woven fabric and manufacturing process thereof

A cupro fiber and manufacturing process technology, applied in the textile field, can solve the problems of expensive cupro fiber, uneven dyeing and high cost, and achieve the effects of excellent wearing performance, good wear resistance and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with embodiment.

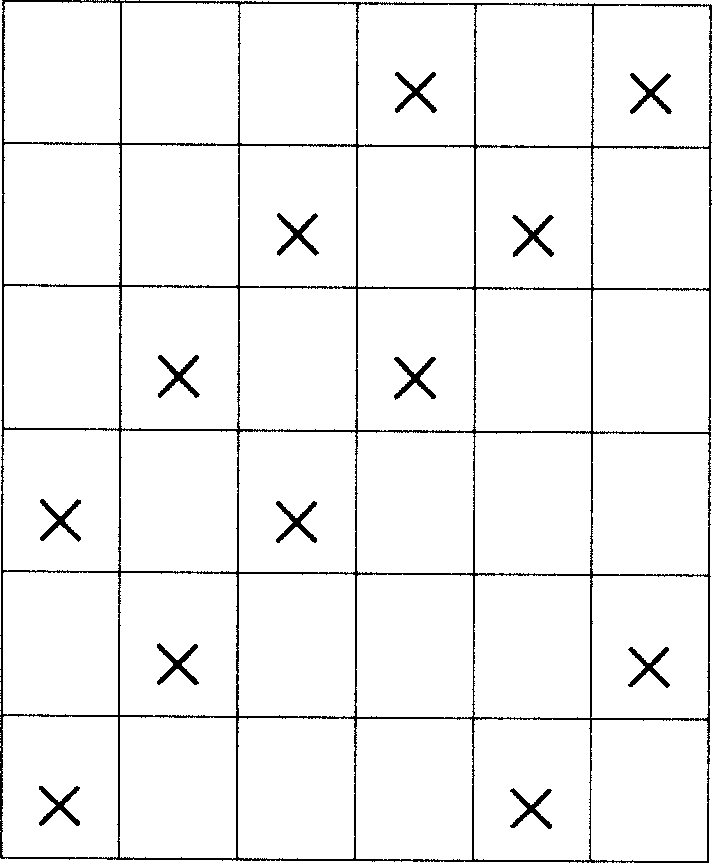

[0054] The cupro ammonia fiber yarn-dyed fabric of this scheme is formed by interweaving pure cotton yarn and cupro fiber yarn. The fabric has a warp of 32S ~40 S Pure cotton dyed yarn, weft is 32 S ~40 S Cupro fiber dyed yarn. The pure cotton dyed yarn and cupro ammonia fiber dyed yarn are combed yarns. The weave of this fabric is a compound twill weave with one up, one down, one up and three down (see attached figure 1 ) or plain poplin.

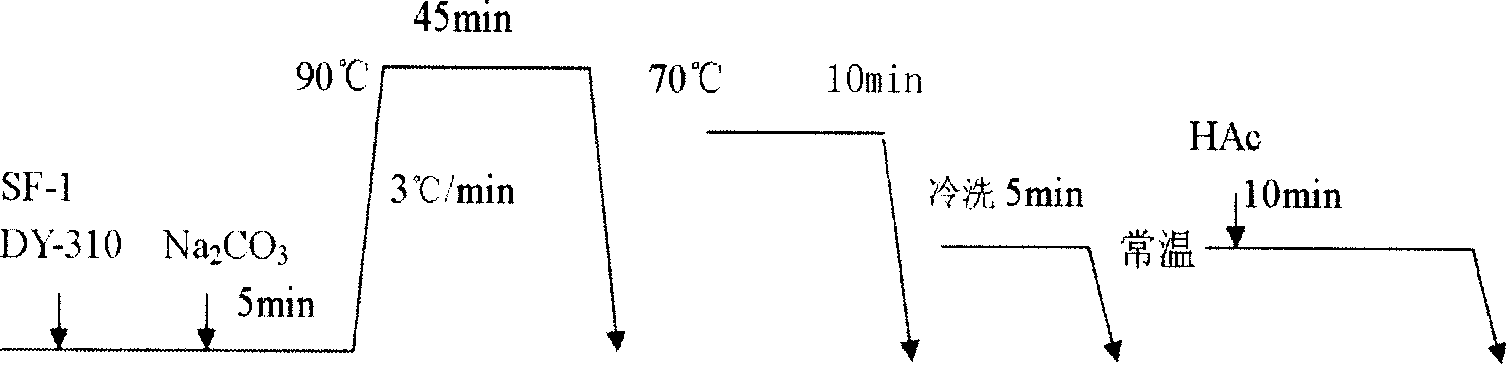

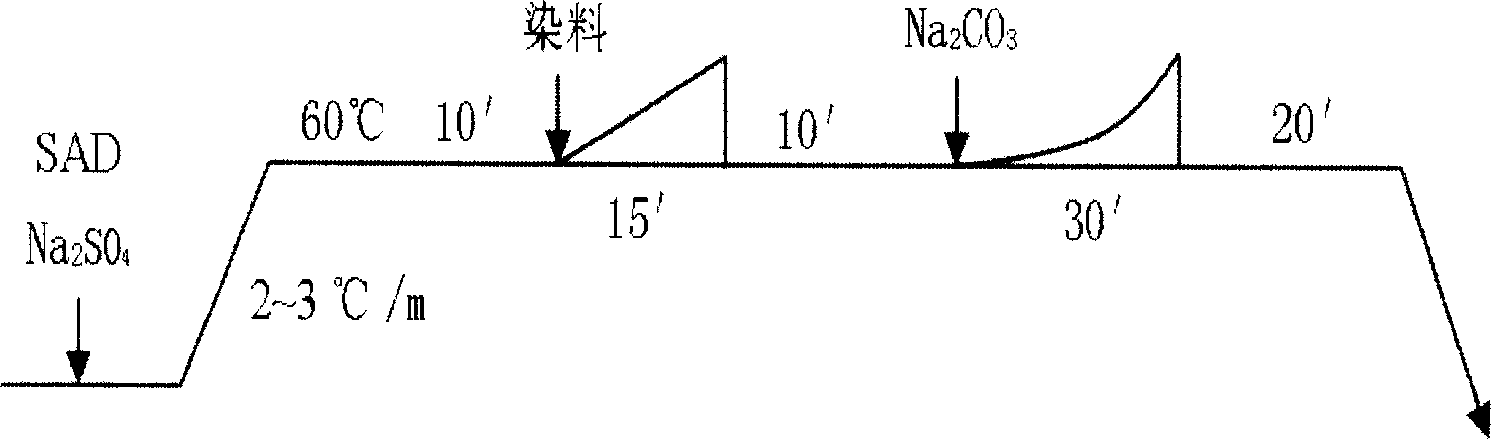

[0055] Its manufacturing process of the fabric of this program comprises the following steps:

[0056] (1) Yarn preparation: the fabric includes warp yarns and weft yarns.

[0057] (1) warp: choose 32 S ~40 S Dyed combed cotton yarn.

[0058] (2) Weft yarn: choose 32 S ~40 S Copper ammonia fiber package yarn is loosely wound by DP1-W precision digital winding loose type winding machine from Swiss SSM company, and the package yarn dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com