Particle analyzer of sheath-flow impedance method

A particle analyzer and impedance method technology, used in individual particle analysis, particle and sedimentation analysis, and analysis of materials, etc., can solve the problems of high driving pressure of the back sheath flow, liquid consumption, and difficulty in signal identification, so as to avoid the shunt effect, Guaranteed effectiveness and noise isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

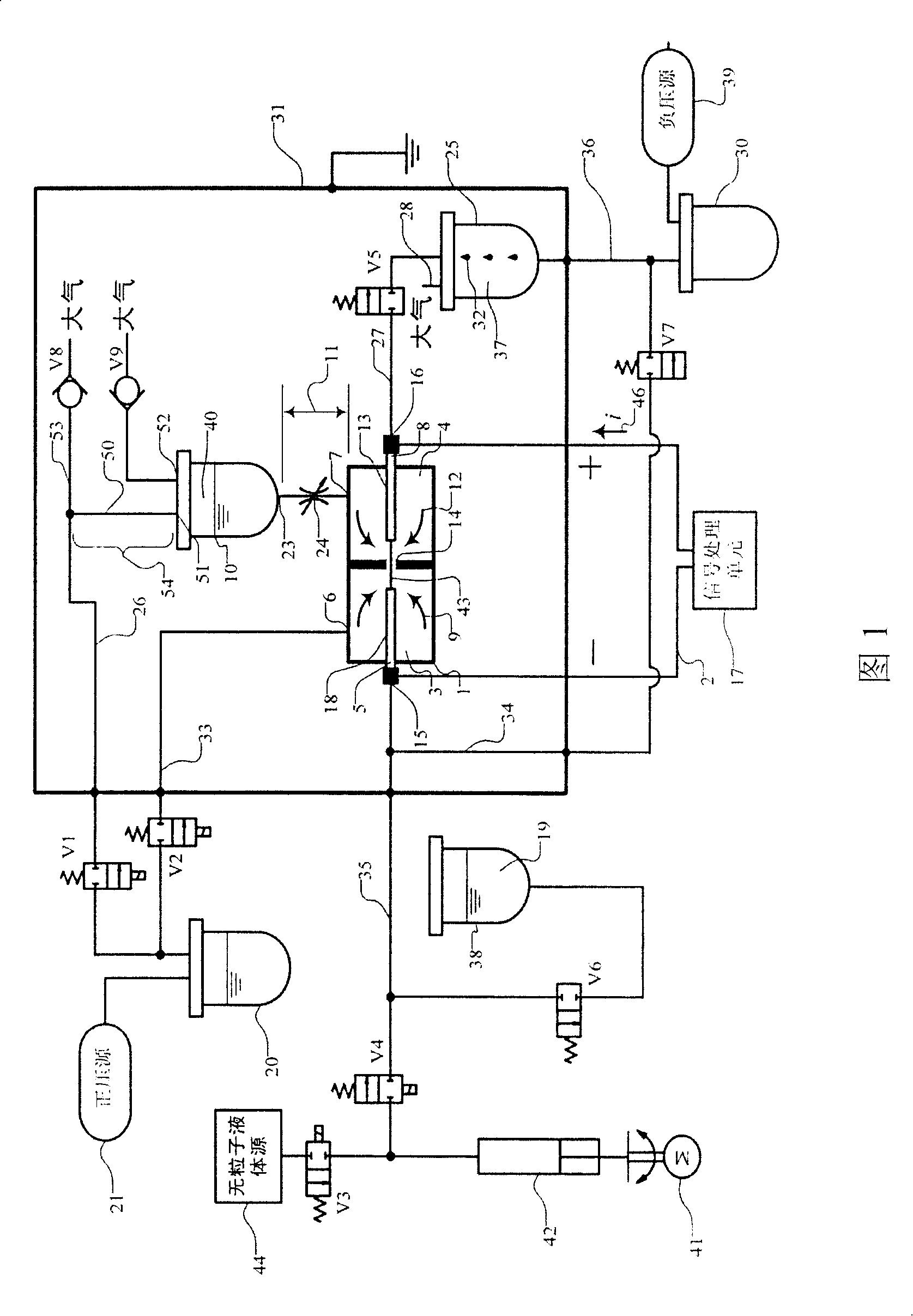

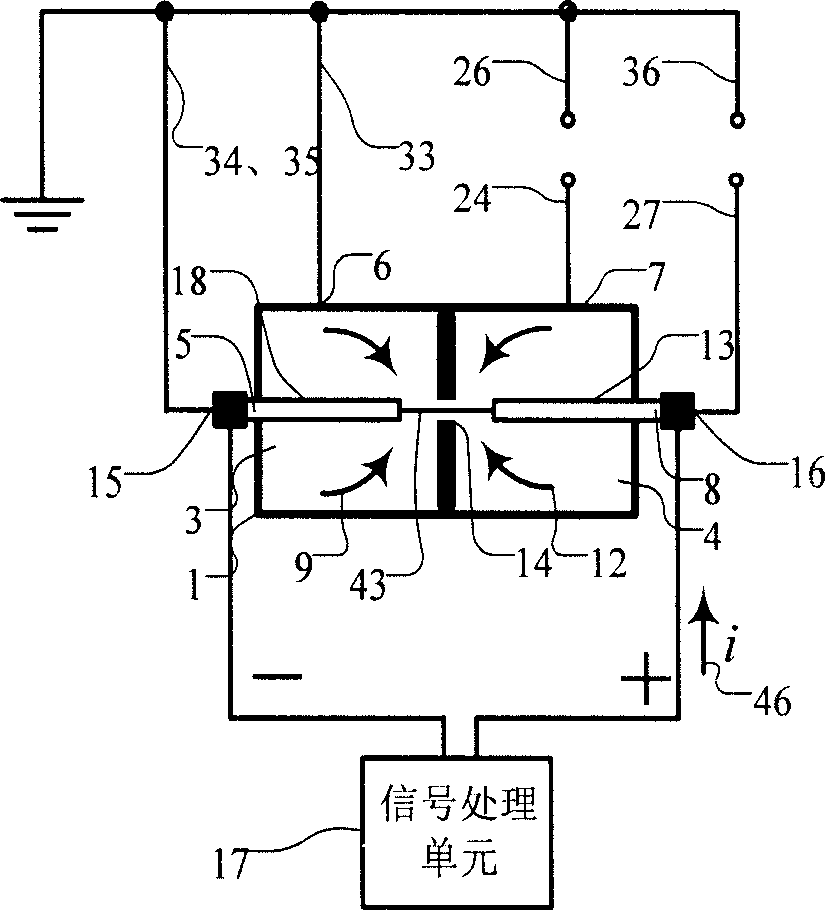

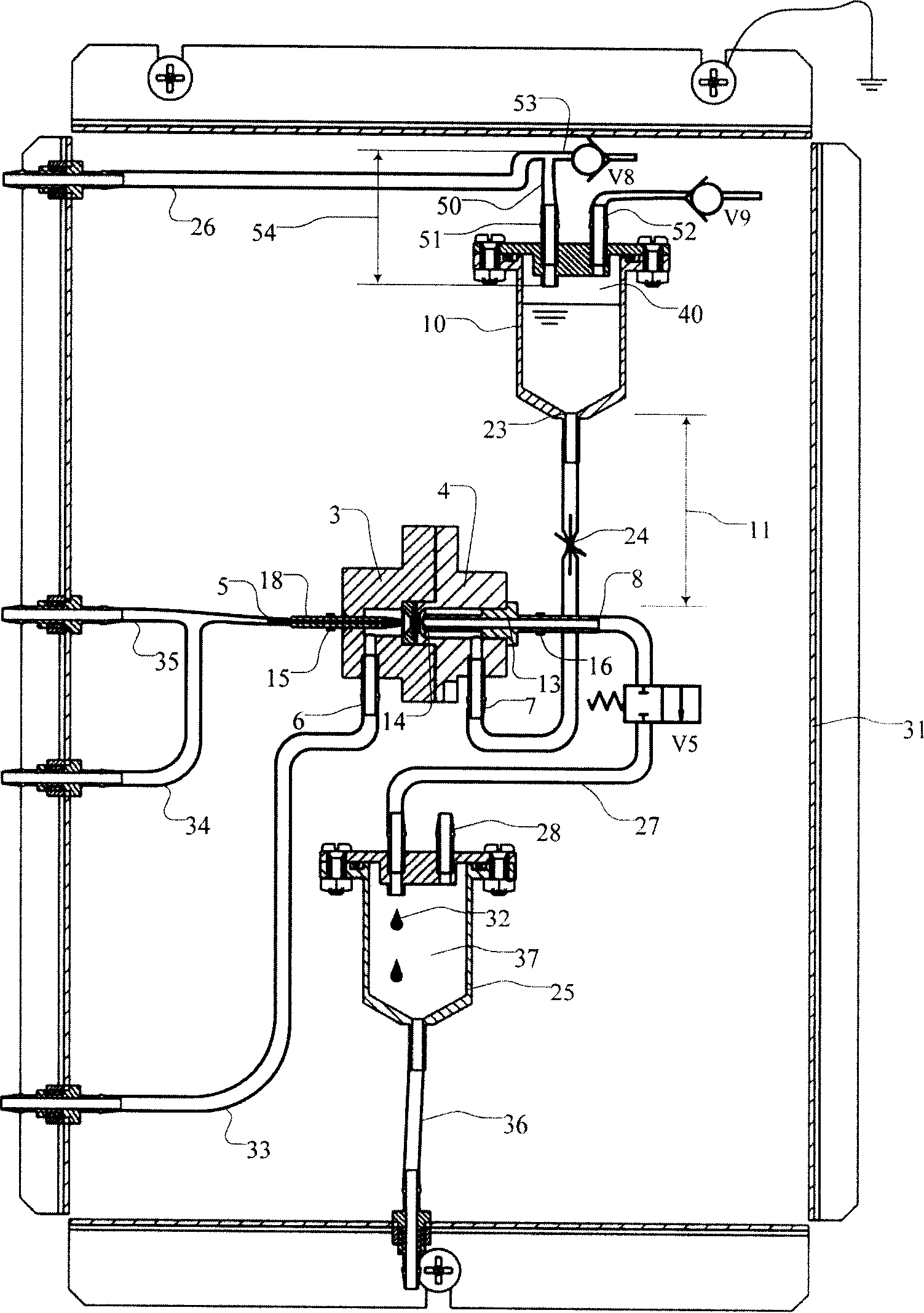

[0042] As shown in FIGS. 1 and 3 , a sheath flow impedance particle analyzer according to an exemplary embodiment of the present invention includes a counting cell 1 and a counting circuit 2 . The counting tank 1 includes a front tank 3 and a rear tank 4, the front tank 3 includes a particle suspension inlet 5 (served by the sample needle 18 at an end outside the counting tank) and a front sheath fluid inlet 6, the rear tank 4 Including a rear sheath liquid inlet 7 and a waste liquid outlet 8 (acted by the outlet pipe 13 at the end outside the counting cell); the front and rear sheath liquids are conductive and particle-free, which are respectively in the front and rear cells during use Form the front and rear sheath flows 9,12; the material of the sample needle 18 and the outlet pipe 13 is conductive metal; a rear sheath isolation pool 10 is located at a position higher than the counting pool 1 (especially the rear pool 4), and it is at the liquid level The back sheath flow 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com