Energy-saving control method of oil pumping machine

An energy-saving control and pumping unit technology, which is applied in the direction of AC motor control, control system, and optimized efficiency control at low load, to achieve the effect of increasing the number of strokes, reducing pump leakage, and shortening the stroke cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

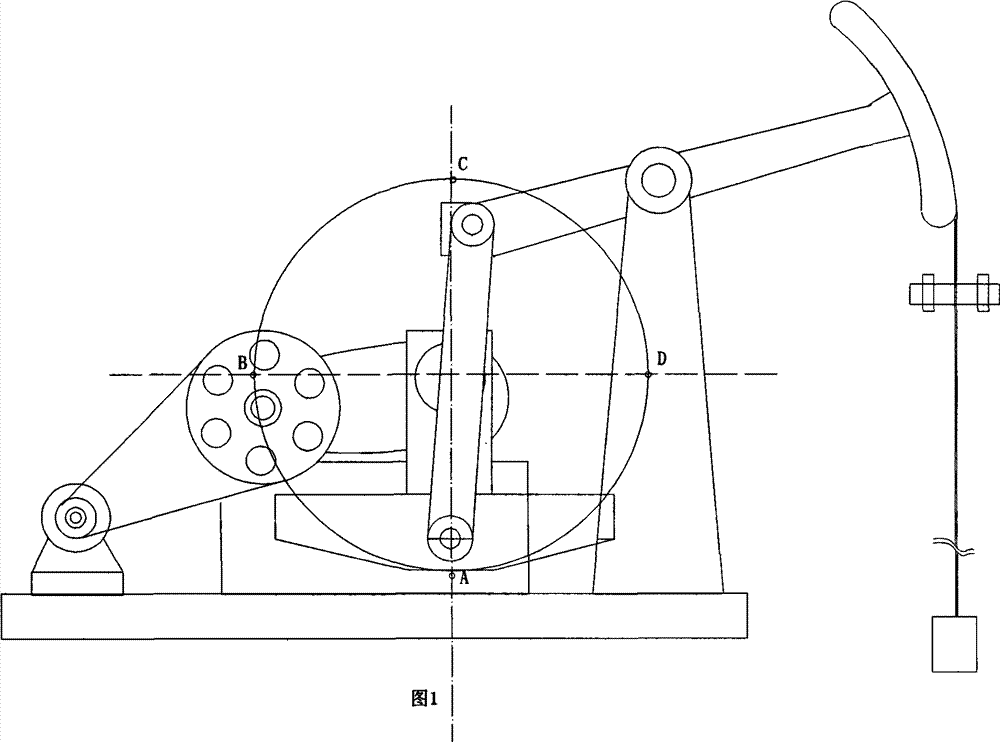

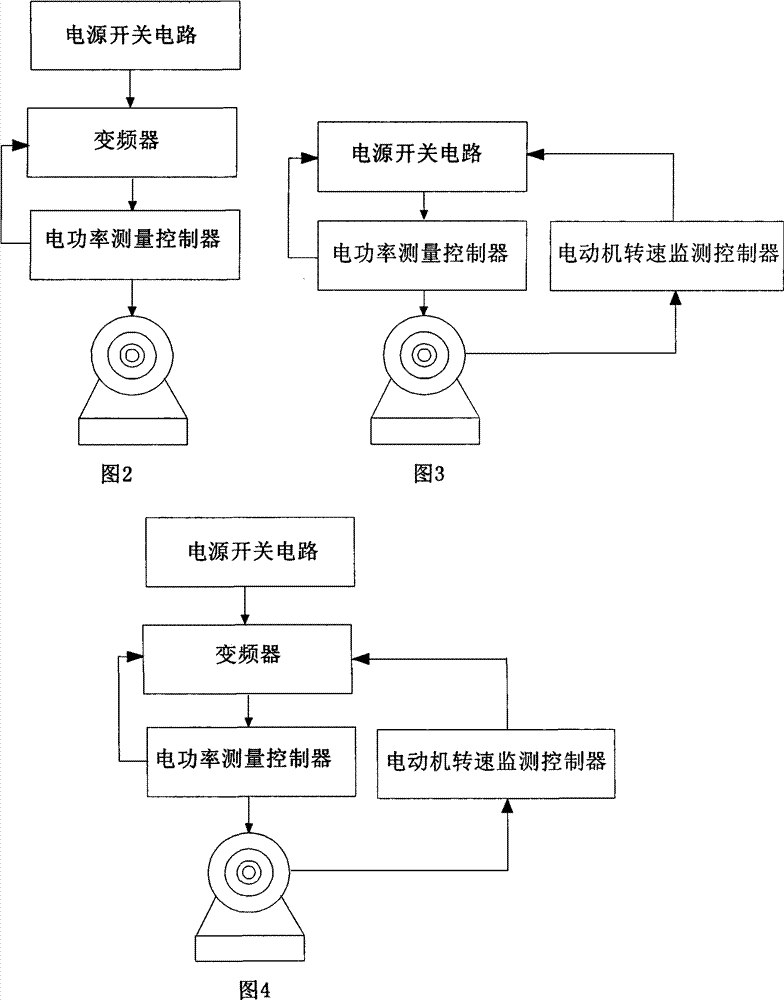

[0023] The method of the present invention can avoid the inconvenience of changing the belt pulley when changing the stroke times of the pumping unit due to changes in geological conditions; the balance of the pumping unit is adjusted so that the equivalent gravity of the counterweight of the pumping unit is greater than the equivalent gravity of the donkey head load of the pumping unit , the head is light and the tail is heavy, that is, after the natural stop, the counterweight is still at the vertically lower position to set point A. (Such as figure 1 , figure 2 (shown) When the pumping unit is running: when the counterweight runs from the vicinity of point A to point B, the motor does positive work and gradually increases to the maximum value, and then runs from point B to a point between C and D. When the equivalent gravity on both sides of the beam is close to the same, the positive work done by the motor gradually decreases to the minimum value. In this operating range...

Embodiment 2

[0026] An electric power measurement controller is set at the output end of the motor power switch circuit, and a motor speed measurement controller is set between the motor and the motor power switch circuit to implement automatic tracking intermittent power supply control for the motor. The control method is: ①When the pumping unit counterweight moves Between points C and D, the equivalent gravity on both sides of the beam is equal, and when the positive work done by the motor approaches zero, the electric power measurement controller controls the motor power switch circuit to turn off the motor power supply. At this time, the sucker rod moves upward rapidly. ;②When the counterweight moves between points A and B or close to point A under the action of inertia, the inertia consumption generated by the gravitational potential energy gradually approaches zero, and when the motor speed drops to the set speed, the motor speed measurement controller Control the motor power switch c...

Embodiment 3

[0028] The method of the present invention is to control the intermittent power supply of the motor by measuring the motor shaft speed and the power consumption of the motor, such as figure 1 , Figure 4 As shown, when the counterweight moves to a certain point between C and D, and the positive power of the motor is about to approach zero, the positive power detected by the electric power measurement controller is close to zero, and the inverter is immediately controlled to stop supplying power to the motor. powered by. Under the action of the gravitational inertial potential energy of the counterweight, the pumping unit freely runs downwards to between points A and B (or moves close to point A), and when the inertia consumption generated by the gravitational potential energy gradually approaches zero, it is controlled by the motor speed measurement When the online converter detects that the motor speed drops to the original rated speed, it immediately controls the frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com