Catalyzer for preparing propylene from methanol or dimethyl ether in high selectivity and preparation method thereof

A high-selectivity, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsuitable propylene as the target product MTP process and high ethylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

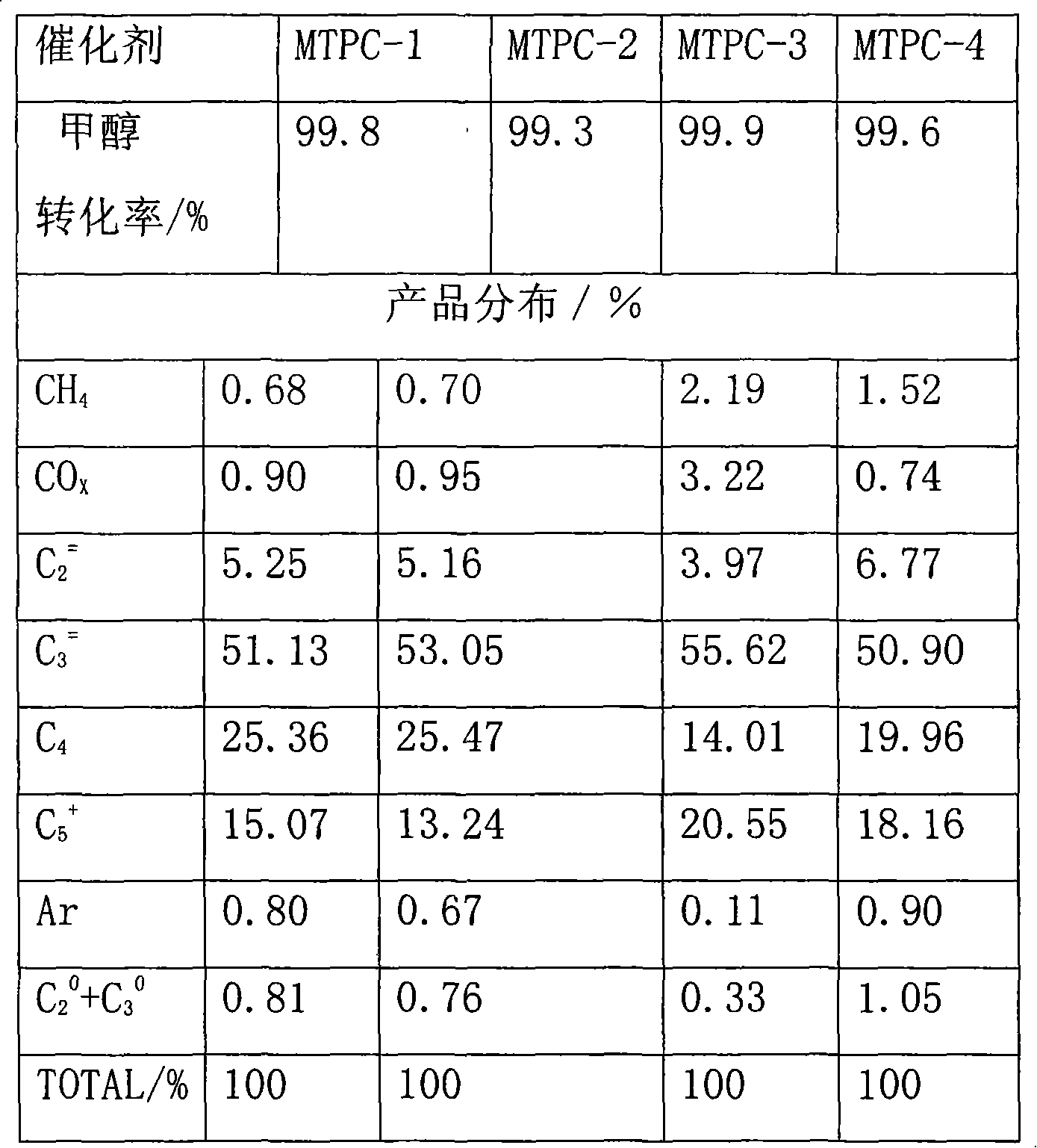

Examples

Embodiment 1

[0018] Get ZSM-5 zeolite former powder 1000g (SiO 2 / Al 2 o 3 =200), the impregnation of La was carried out at room temperature. Lanthanum nitrate solution 1500g, La loading 3%, soak at room temperature for 24 hours, heat up to boiling, and stir at the same time, stop stirring when it becomes viscous, heat up to 120°C for drying, and then bake in air at 600°C for 3 hours , to obtain La / ZSM-5 zeolite. Weigh 1560g of 85% concentrated phosphoric acid (alkaline modifier), 1420g of pseudo-boehmite (binder) with a dry basis of 65%, 6000g of deionized water, stir and react for 20 minutes, add La / ZSM-5 Zeolite, stirring for 20 minutes, colloid mill grinding for 30 minutes, spray molding. Control the inlet temperature of the spray dryer to 400°C, the outlet temperature to 200°C, and the injection pressure to 2.0MPa. The formed catalyst microspheres were calcined at 600°C for 3 hours. After cooling, exchange with 0.1 mol / l hydrochloric acid, the ratio of liquid volume (ml) to cata...

Embodiment 2

[0020] Get ZSM-5 zeolite former powder 1000g (SiO 2 / Al 2 o 3 =200), the impregnation of La was carried out at room temperature. Lanthanum nitrate solution 1500g, La loading 3%, soak at room temperature for 24 hours, heat up to boiling, and stir at the same time, stop stirring when it becomes viscous, heat up to 120°C for drying, and then bake in air at 600°C for 3 hours , to obtain La / ZSM-5 zeolite. La / ZSM-5 zeolite was subjected to Mg leaching treatment using the same operation as leaching La, and the Mg loading was 3.2%. Weigh 3567g of kaolin with a dry basis content of 84%, 6000g of deionized water, and the above-mentioned PLA / ZSM-5 zeolite, stir for 30 minutes, grind with a colloid mill for 30 minutes, and spray to form. Other operations are the same as in Example 1. The prepared catalyst was labeled MTPC-2.

Embodiment 3

[0022] Catalyst preparation was carried out according to Example 2, and the silanization time was 2 hours. Catalyst MTPC-3 was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com