Oscillatory type double roll strip casting mill

A twin-roll thin strip, casting and rolling mill technology, applied in the field of metallurgical machinery, can solve the problems of segregation, cracks, delamination, easy deposition of impurities, etc., to achieve uniform distribution of alloy components, reduce segregation, and refine grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

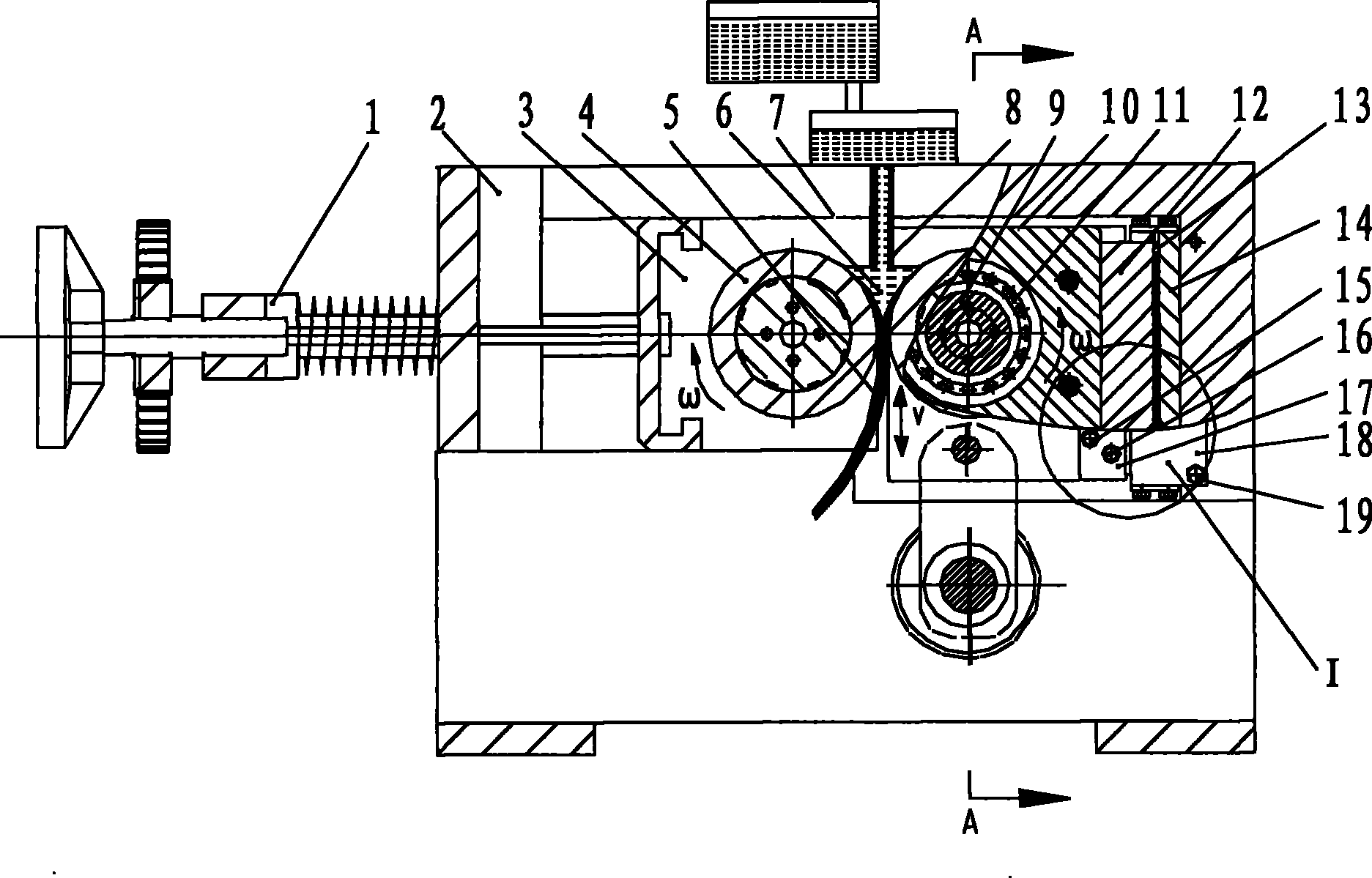

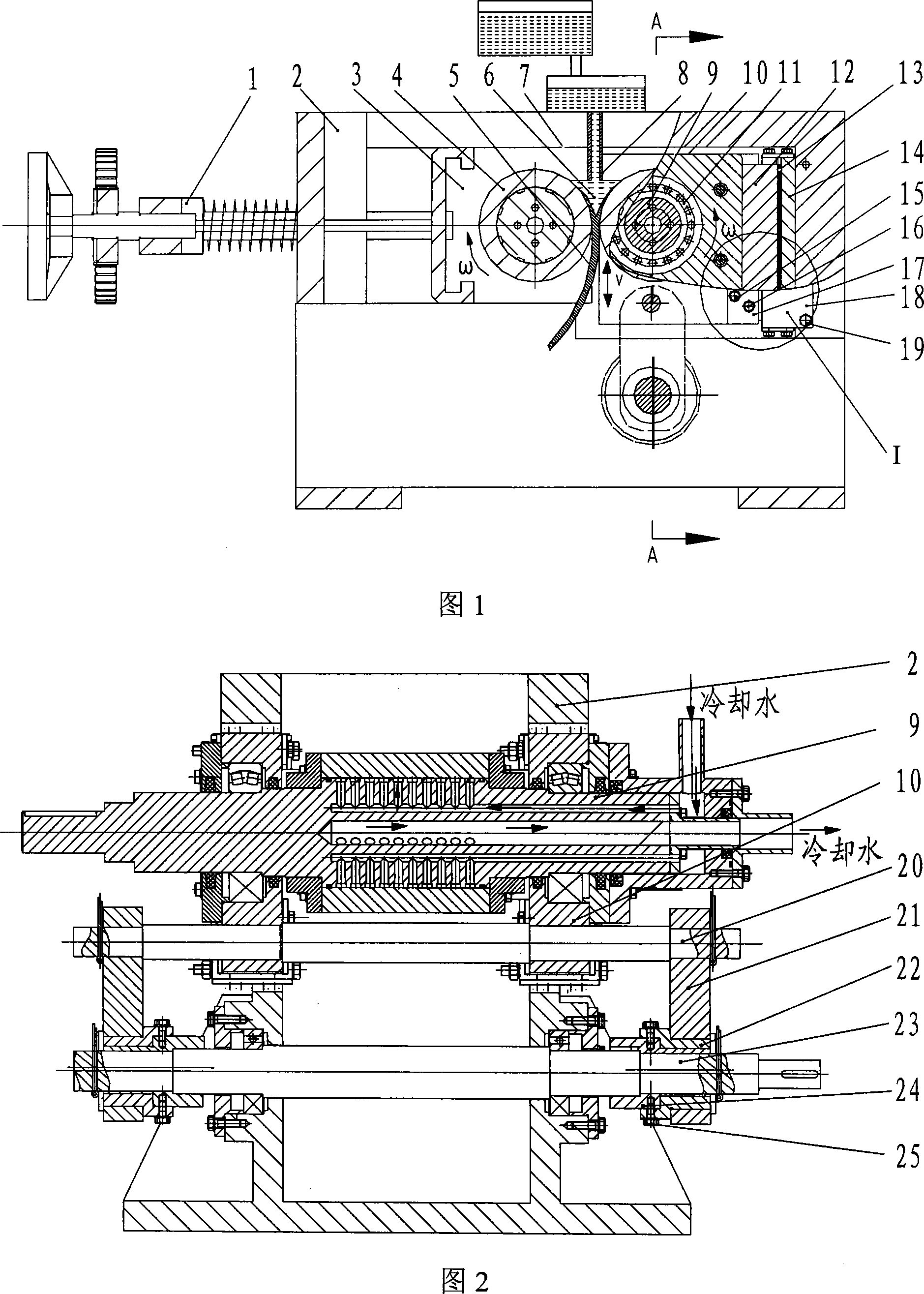

[0016] Embodiment 1 mechanical vibration type twin-roll strip casting and rolling mill

[0017] Fig. 1 is a mechanical vibrating twin-roll strip casting mill disclosed by the present invention. One end of the connecting rod 21 is sleeved on the vibration shaft 20, and the other end is sleeved on the rotating shaft 23, and the vibration shaft 20 is installed on the bottom of the vibration side bearing block 10 (see FIG. 2). A crank device is set on the rotating shaft 23, and the crank device is composed of an outer eccentric sleeve 22 and an inner eccentric sleeve 24, both of which have eccentricity, and are fixed together by screws 25 after a relative rotation of an angle to form an eccentricity Different cranksets.

[0018] The inner ring of bearing 11 is equipped with vibration side casting roll 9, and bearing 11 is installed in the vibration side bearing block 10. The casting roller 4 on the non-vibrating side is installed in the bearing seat 3 on the non-vibrating side, ...

Embodiment 2

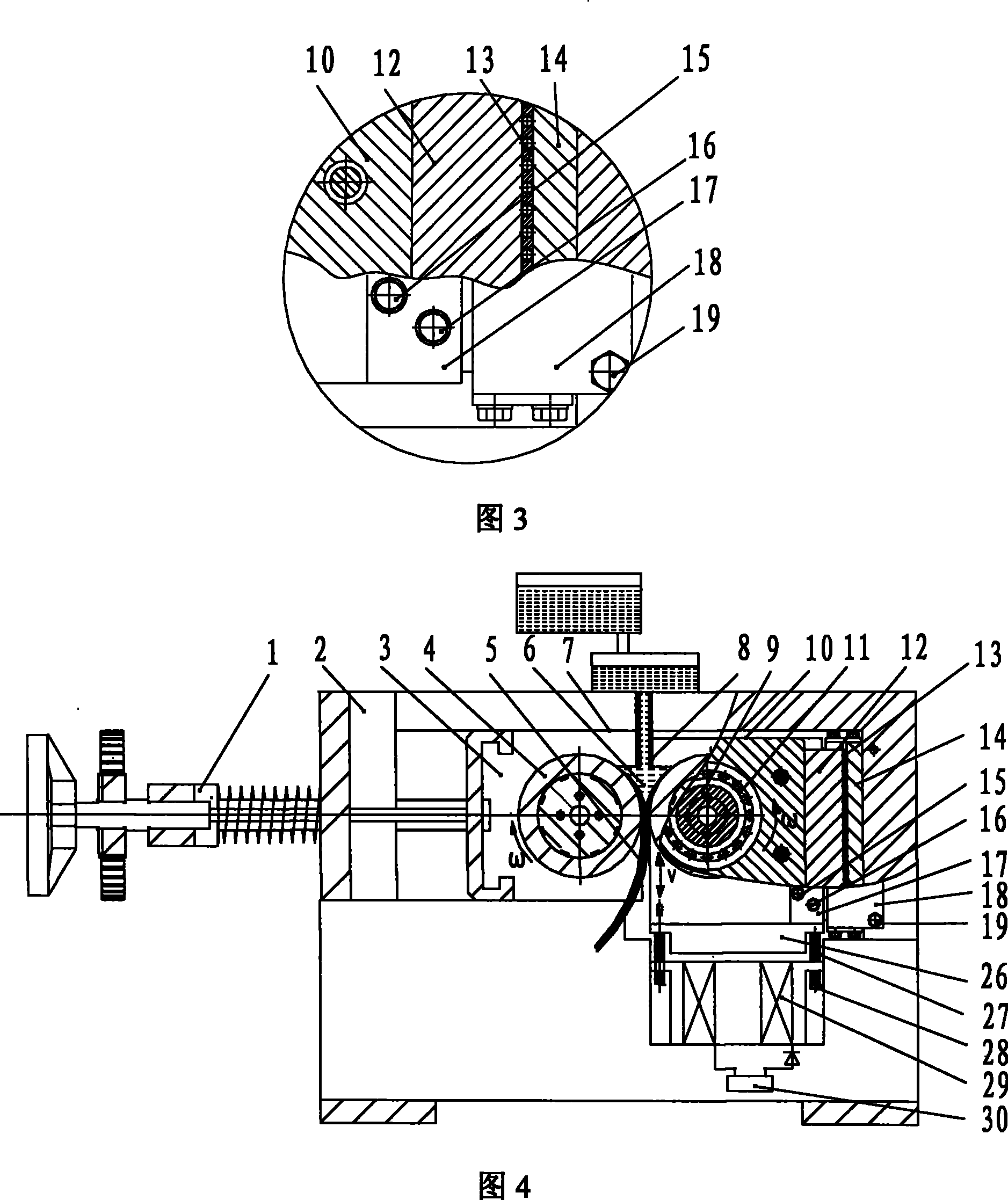

[0036] Embodiment 2 Electromagnetic vibration type twin-roll strip casting and rolling mill

[0037] As shown in FIG. 4 , the electromagnetic vibration vibration device is mainly composed of an armature 26 , a spring 27 , an armature mandrel 28 , an electromagnetic coil 29 and a current regulator 30 . The armature mandrel 28 constrains the spring 27 and fixes the armature 26 and the vibration side bearing seat 10 together. The current regulator 30 controls the magnitude, direction and frequency of the current. Vibration side bearing seat 10 and its accessory parts move downward, and when electric current disappears, electromagnetic force also disappears, and vibration side bearing seat 10 moves up to original position under the effect of spring 27, has just finished a process of vibration like this. The amplitude and frequency of the armature 26 is controlled by a current regulator 30 .

Embodiment 3

[0038] Embodiment 3 Hydraulic vibration type twin-roll strip casting and rolling mill

[0039] The hydraulic vibration device is mainly composed of a vibration piston 31, a spring 32, a mandrel 33, hydraulic oil 34, a hydraulic cylinder 35, and a hydraulic servo system 36. The mandrel 33 fixes the vibrating side bearing housing 10 and the vibrating piston 31 together, the hydraulic cylinder 35 is fixed on the frame 2, the hydraulic oil 34 is controlled by the hydraulic servo system 36, and the vibration frequency and amplitude of the vibrating piston 28 are controlled by the hydraulic servo system 32 to control.

[0040] When the system works, the servo system 36 makes the hydraulic oil 34 flow to the hydraulic cylinder 35, and the hydraulic oil 34 is in a high-pressure state. At a certain position, the servo system 36 makes the hydraulic oil 34 flow out of the hydraulic cylinder 35, and when the hydraulic oil 34 is in a low-pressure state, the bearing housing 10 on the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com