Low-temperature leadless porcelain enamel composition and preparation method thereof

A technology of lead-free enamel and composition, which is applied in the field of enamel materials and preparation, and can solve problems such as plating corrosion, zinc unfavorable enamel adhesion, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Base glaze: SiO 2 31%, TiO 2 20%, Na 2 O 23%, K 2 O 14%, introducing Sb 2 o 3 0.2%, Li 2 O 1.6%, ZrO 2 0.2%, V 2 o 5 10%; the melting temperature is 1250°C, the melting time is 60 minutes, and the glass frit is directly poured into water to quench after melting. The aluminum-zinc-coated steel plate is soaked with 5% citric acid for 2 minutes, then rinsed with water, and dried; weigh 50g of glass frit, and weigh and add grinding materials: 4g of boric acid, 1g of potassium hydroxide, 1g of sodium silicate, 4g of titanium oxide, Pigment 1g; then add 25ml of water, and use a planetary ball mill to mill for 60 minutes; pass the slurry through a 200-mesh sieve, pour the sieved material into the spray gun, and spray evenly on the galvanized substrate, once coated, and dried Firing, the firing temperature is controlled at about 530°C, and the firing time is 2.5 minutes.

Embodiment 2

[0027] Base glaze: SiO 2 35%, TiO 2 22%, Na 2 O 20%, K 2 O 13%, introducing Sb 2 o 3 0.2%, Li 2 O 1.6%, ZrO 2 0.2%, V 2 o 5 8%; the melting temperature is 1250°C, and the melting time is 60 minutes. After melting, directly pour the glass frit into water to quench; the aluminum-zinc steel plate is burned at 600°C for 5 minutes; weigh 50g of glass frit, add it to the mill Additives: boric acid 5g, potassium hydroxide 1g, sodium silicate 1g, titanium oxide 4g, pigment 1g; then add 25ml of water, and use a planetary ball mill to mill for 60min; Pour into the spray gun, spray evenly on the galvanized steel plate, coat once, dry and then fire, the firing temperature is controlled at about 550°C, and the firing time is 2.5 minutes.

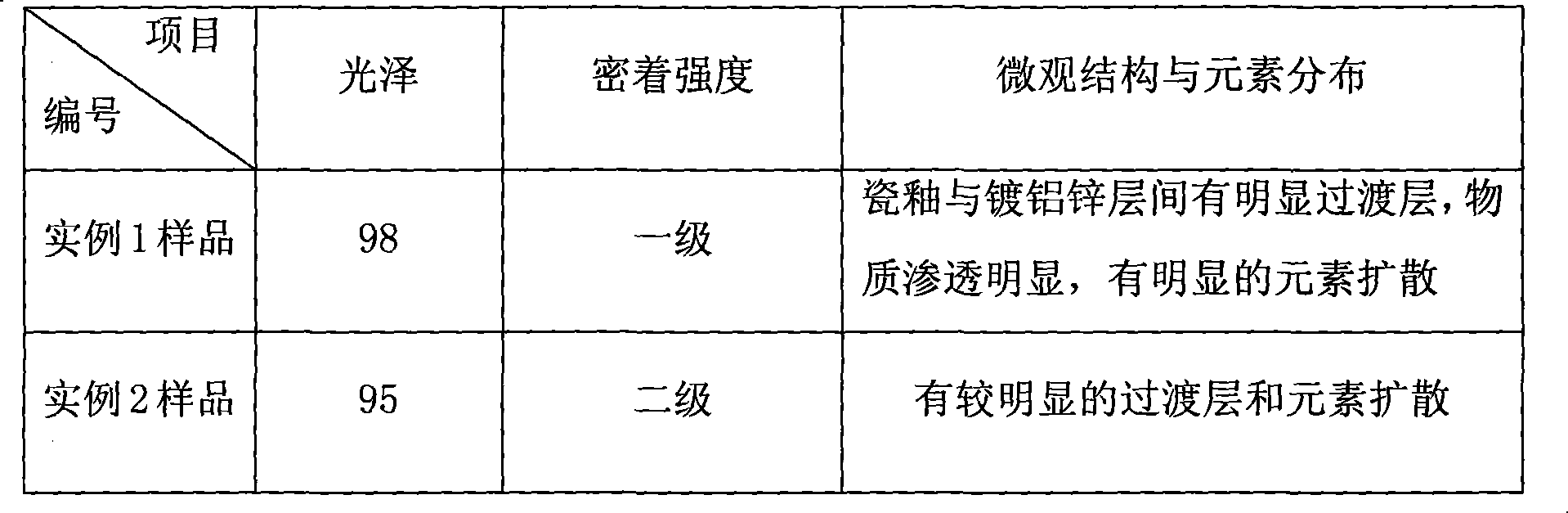

[0028] Table 1 shows the test results of the samples of Examples 1 and 2, wherein gloss: in accordance with the provisions of GB11420-89 "Enamel Gloss Test Method"; adhesion strength: in accordance with the provisions of the EU enamel test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com