Fuel direct injection in cylinder liquefied petroleum gas engines

A technology of liquefied petroleum gas and in-cylinder direct injection, applied to internal combustion piston engines, engine components, engine control, etc., can solve the problem of limiting engine performance and improving gas economy, limiting the response speed of liquefied petroleum gas supply and combustion control, Affect the engine charging efficiency and other issues to achieve the effect of improving performance and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

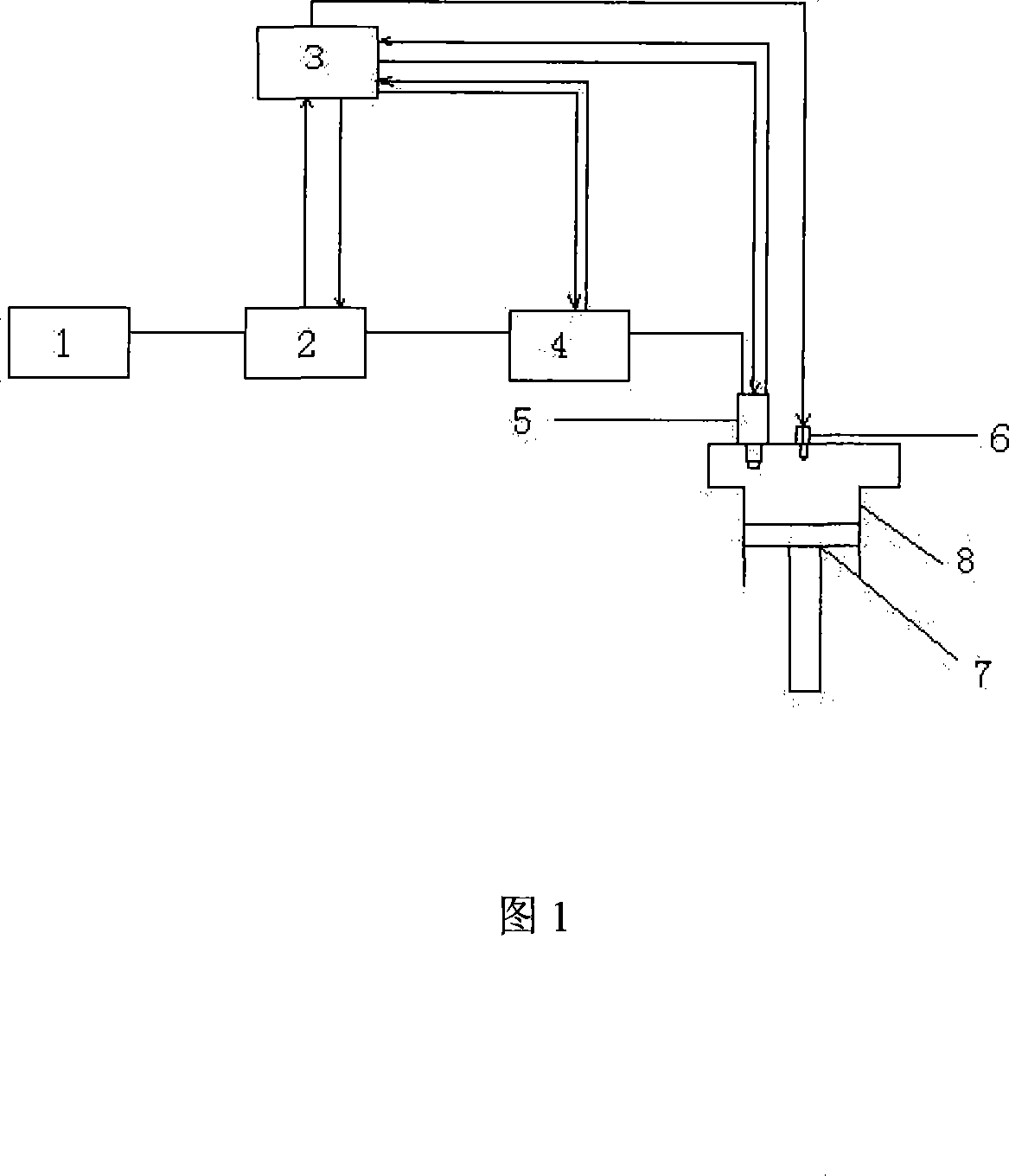

[0009] The present invention will be further described below in conjunction with the accompanying drawings:

[0010] As shown in the figure, it has a gas nozzle 5, a spark plug 6, an LPG (liquefied petroleum gas) storage device 1, a solenoid valve 2, an LPG booster device 4, an LPG storage device, a solenoid valve, an LPG booster device, and a gas nozzle via The pipelines are connected in sequence; it also has an ECU (vehicle computer) 3 that can adjust the LPG booster device; the ECU can also adjust the gas nozzle 5, the spark plug 6, and the solenoid valve 2; it also has a cylinder block 8 and a piston 7.

[0011] During operation, the liquefied petroleum gas flows out through the LPG storage device 1, and reaches the LPG booster device 4 through the solenoid valve 2. The LPG booster device controls the LPG pressure at about 5Mpa, and then directly injects it into the cylinder 8 through the gas nozzle 5. ECU 3 controls the LPG booster, gas nozzles, spark plugs, and solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com