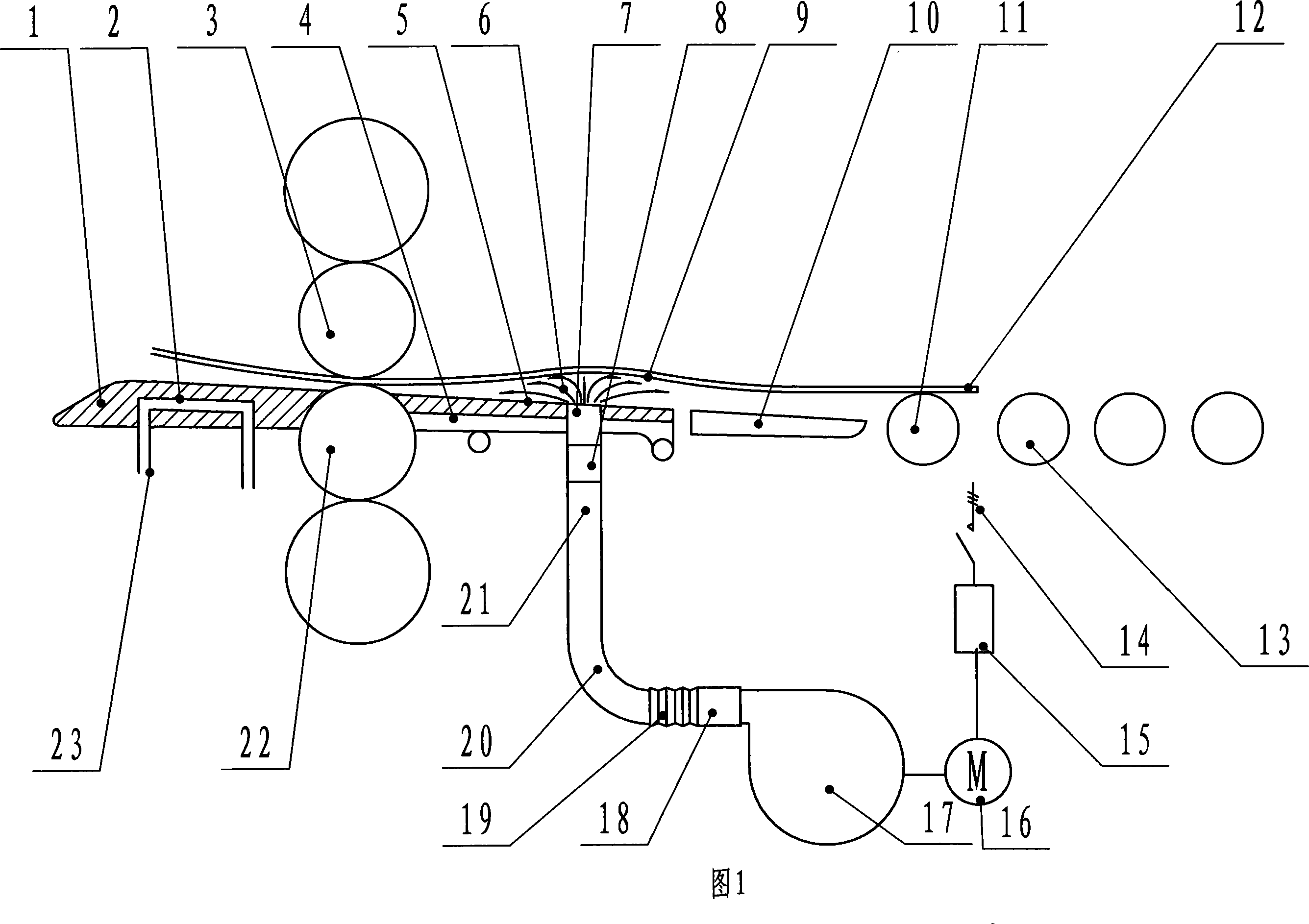

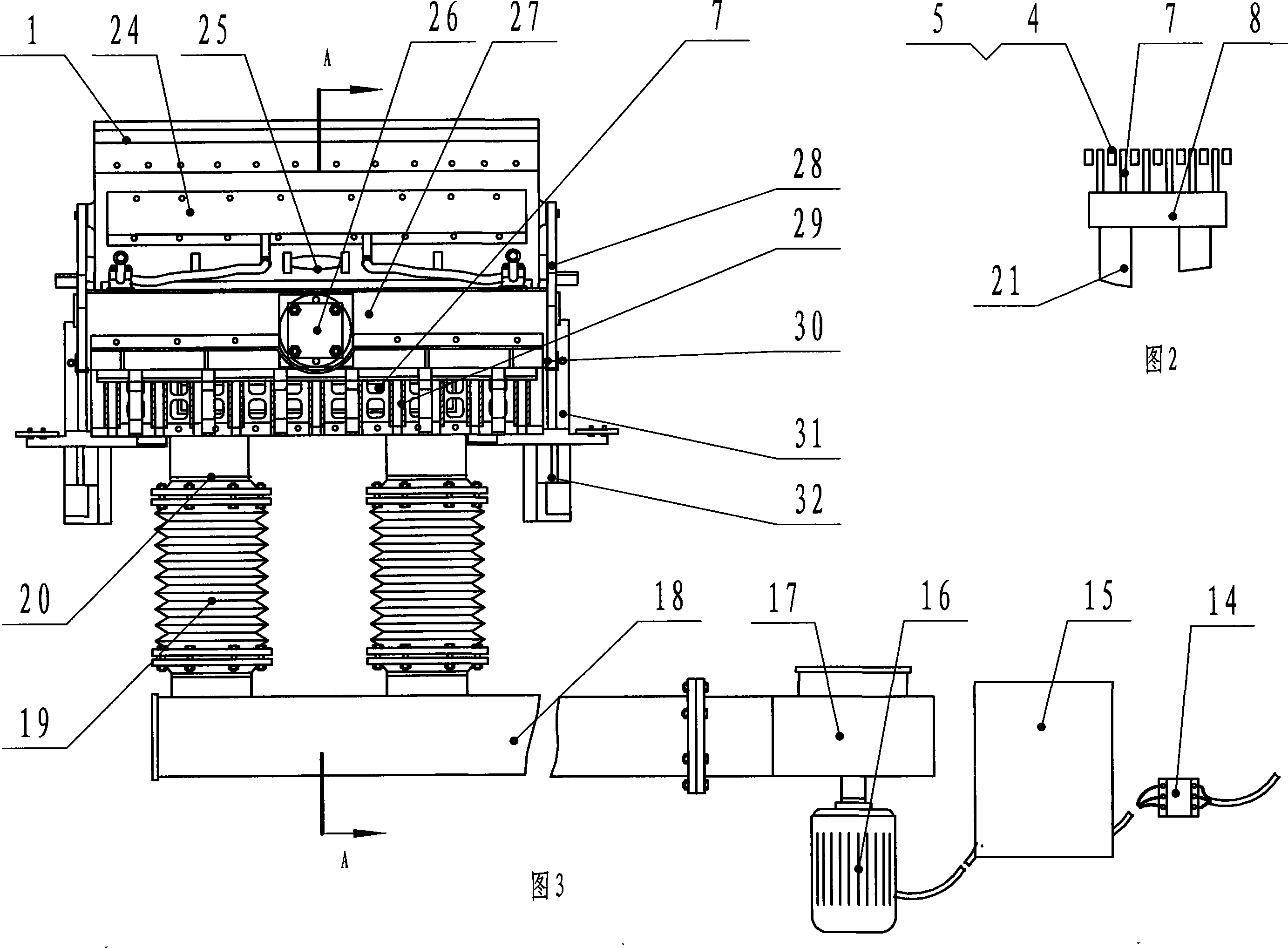

Method for preventing hot rolling stainless steel band from rolling cuts and device thereof

A technology for stainless steel strips and strips, used in metal rolling, metal rolling, guiding/positioning/aligning devices, etc., to reduce replacement time, improve strip surface quality, and prevent scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

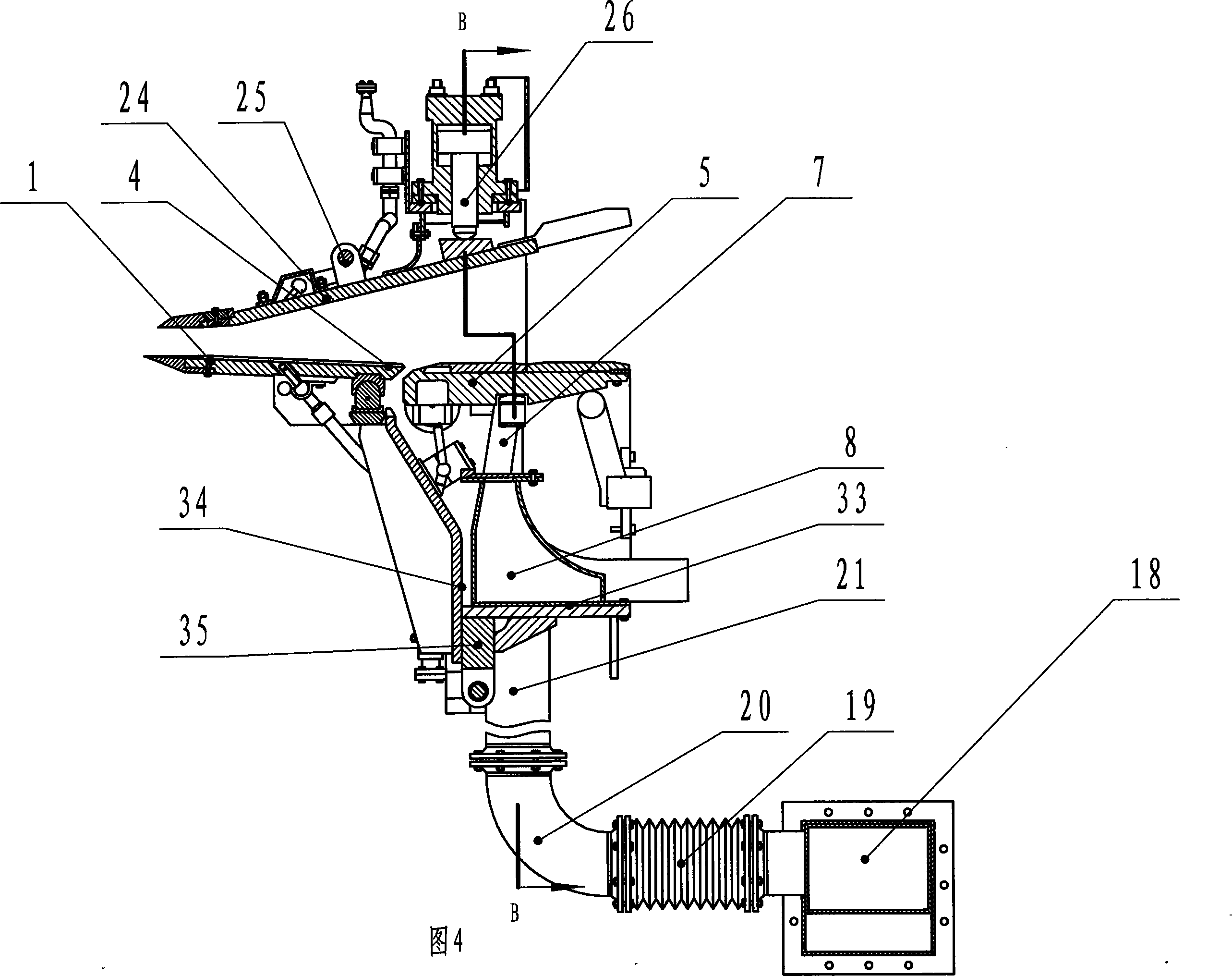

Examples

Embodiment 2

[0044] The difference between this embodiment and method embodiment one is that the control mode of the motor 16 is different from the speed control of the blower 17. The power on and off of the motor 16 in this embodiment is controlled by the travel switch 40 and the switch 14, as shown in FIG. 8, the stroke Switch 40 is positioned at one side of strip steel 8 under strip steel 8, and the distance of the roller 41 of travel switch 40 apart from strip steel 8 one side is not more than 40mm, and travel switch 40 is installed in the longitudinal grid 39 of lower guide body. When the strip steel head 12 arrives at the lower roll 22, the roller 41 of the travel switch 40 is touched, the long-open contact of the travel switch 40 is closed, the coil of the AC contactor as the switch 14 is energized, and the long-open contact of the AC contactor is closed , the motor 16 is energized, the motor 16 drives the speed changer 42 to work, the speed changer 42 drives the blower 17 to work, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com