Tower outside heat exchange device for menthol producing technique

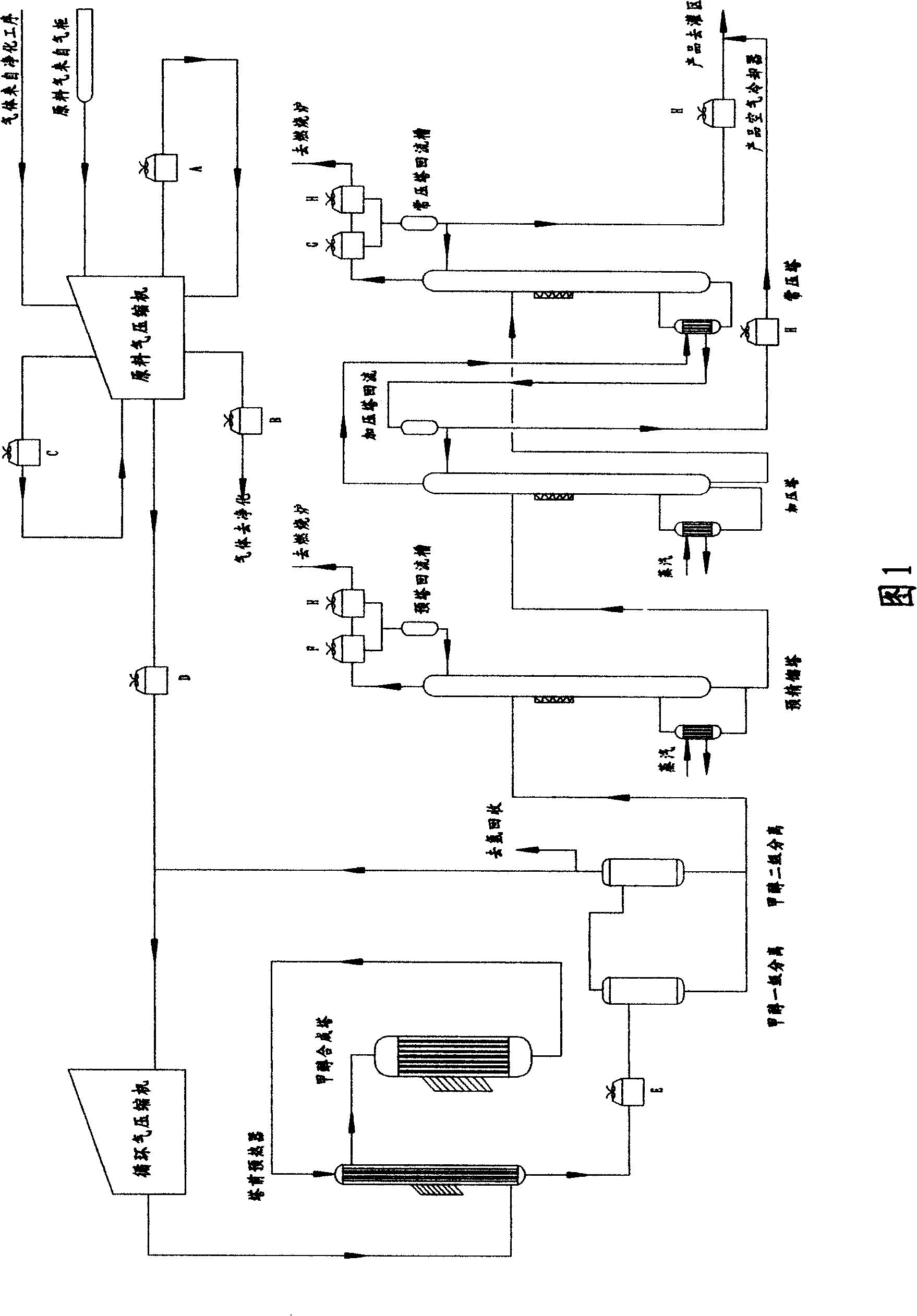

A technology of production process and heat exchange equipment, which is applied in the chemical industry, sustainable manufacturing/processing, carbon dioxide reduction method preparation, etc., can solve the problems of huge power consumption of equipment, reduce one-time investment, reduce production cost, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

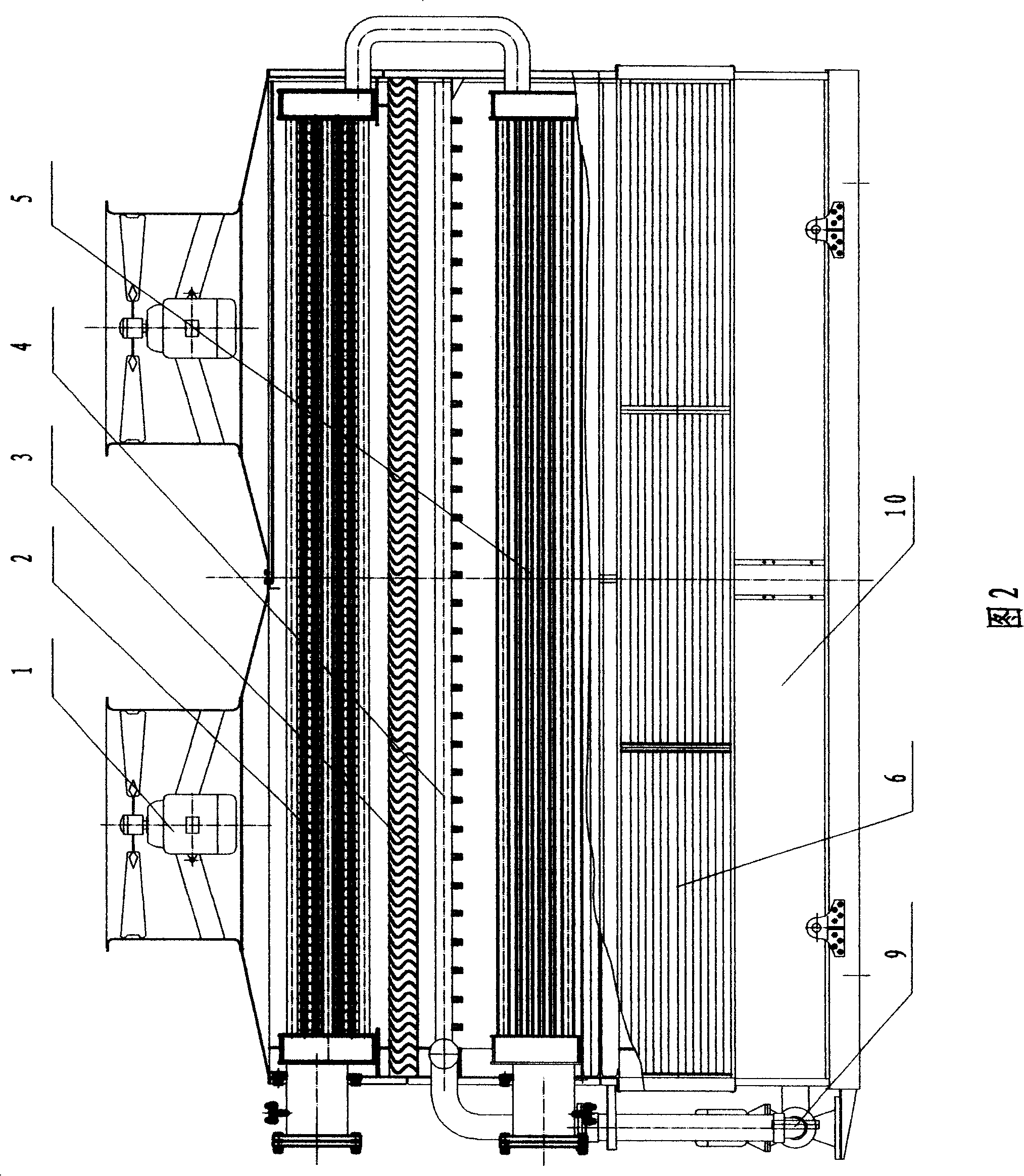

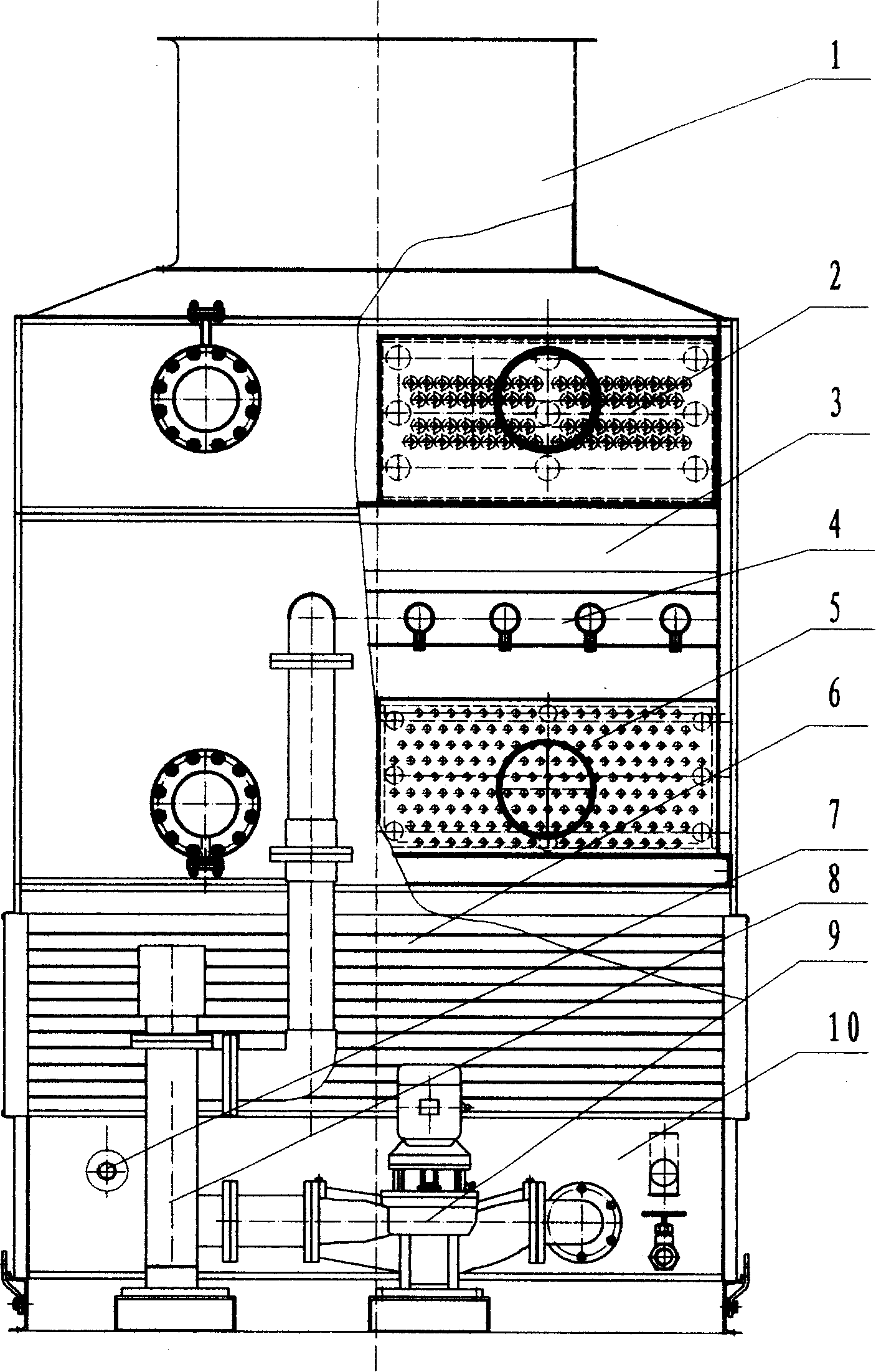

[0028] Its structure is described in conjunction with the embodiment that accompanying drawing provides:

[0029] As shown in Figure 2, image 3As shown, the evaporative air-cooled heat exchanger in this embodiment mainly includes the finned tube group 2 as the precooling section, the heat exchange component 5 of the evaporative heat exchange section, the axial flow fan 1, the water spray device 4 and the inlet Air grid 6; there are also water pumps 9, water tanks 10, etc.; the axial flow fan 1 is located at the uppermost part of the equipment, and the finned tube group 2 cooled by air is arranged horizontally below the axial flow fan, and the finned tube group has multiple rows and multiple fins Both ends of the finned tubes are connected to the tube box, and the tube boxes at both ends are respectively connected to the process fluid inlet and the heat exchange part 5 of the evaporation heat exchange section, so that the high-temperature process fluid first enters the finned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com