Continuous co-production method for high concentration formic acid and high pure sodium hexametaphosphate

A high-concentration technology of sodium hexametaphosphate, applied in the field of preparation of formic acid and sodium phosphate, can solve the problems of discontinuous process flow, low added value, low yield of formic acid, etc., and achieve good economic and environmental benefits , Increase the added value of the product, the effect of high concentration of formic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

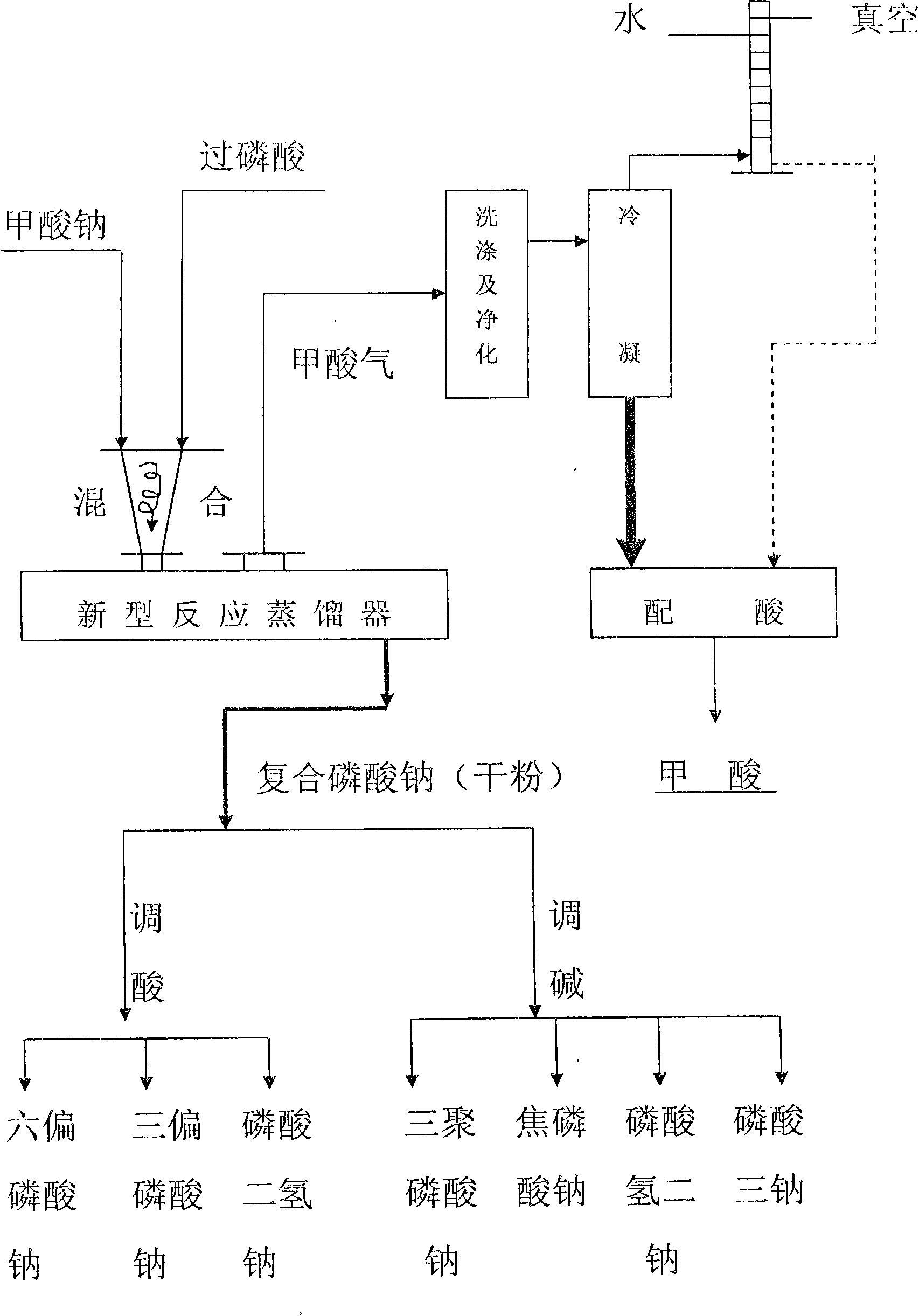

[0015] Will be in P 2 o 5 Superphosphoric acid with a concentration of 76% and sodium formate with a purity of ≥95% are put into the conical mixer at the same time, and the two are mixed instantly to react, and the pressure formed by the generated formic acid gas will press the resulting mixture into the distillation and dry After distillation and drying, the compound phosphate dry powder is obtained; the formic acid gas produced enters the washing dehydration purifier, and is washed, purified and dehydrated with >105% superphosphoric acid, and then enters the condenser to separate the condensed formic acid. The condensation temperature is controlled at 10°C to obtain formic acid with a concentration of 96%, and the non-condensable gas is extracted by vacuum; the produced composite phosphate dry powder automatically flows out from the distillation dryer, and is directly input into the polymerization furnace one after another, and the process is continuously replenished. Phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com