Plating device

A technology of electroplating device and resistor, applied in the direction of current conduction device, plating tank, electrolysis process, etc., can solve the problems of high cost of rectifier, inability to provide uniform current, and different current values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

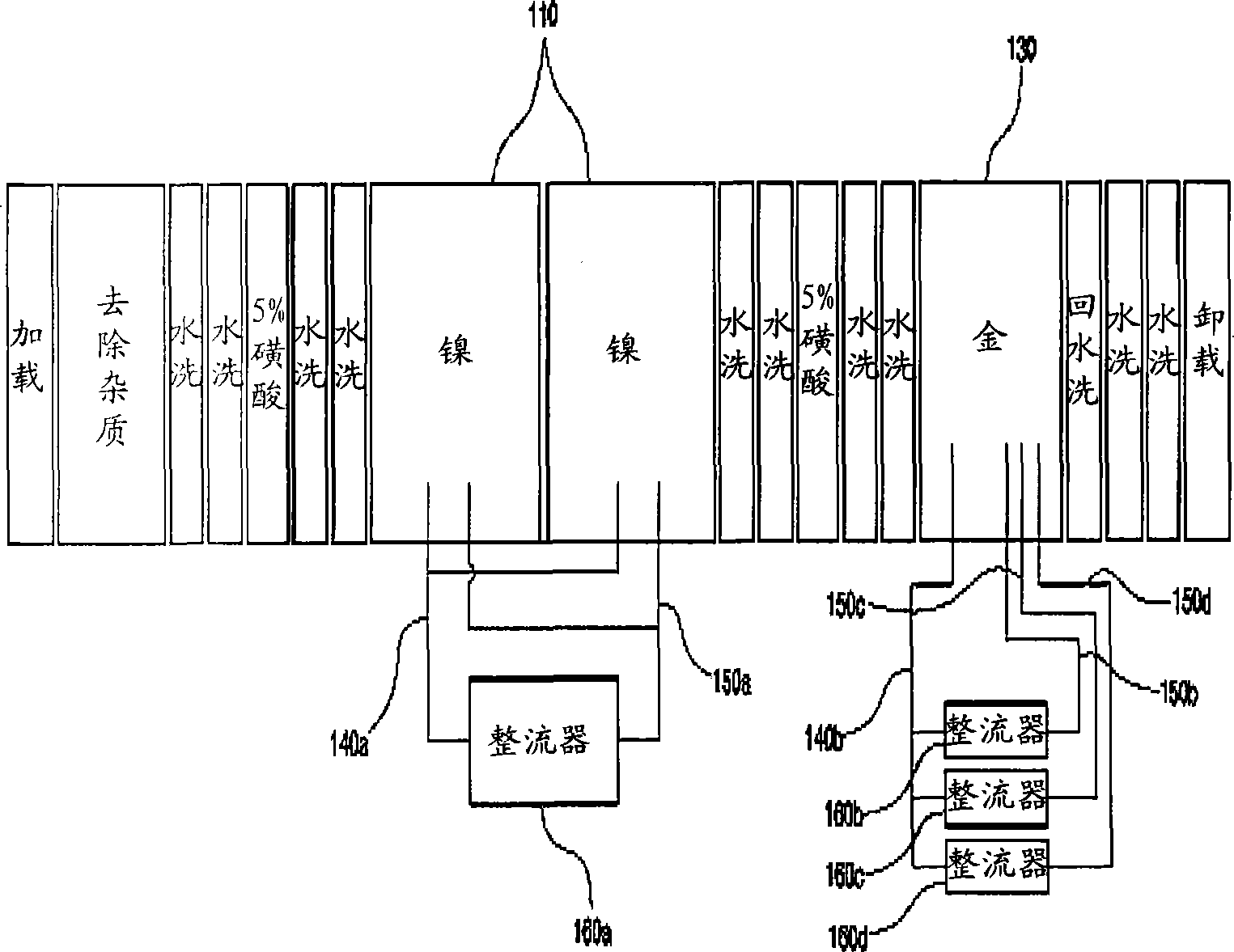

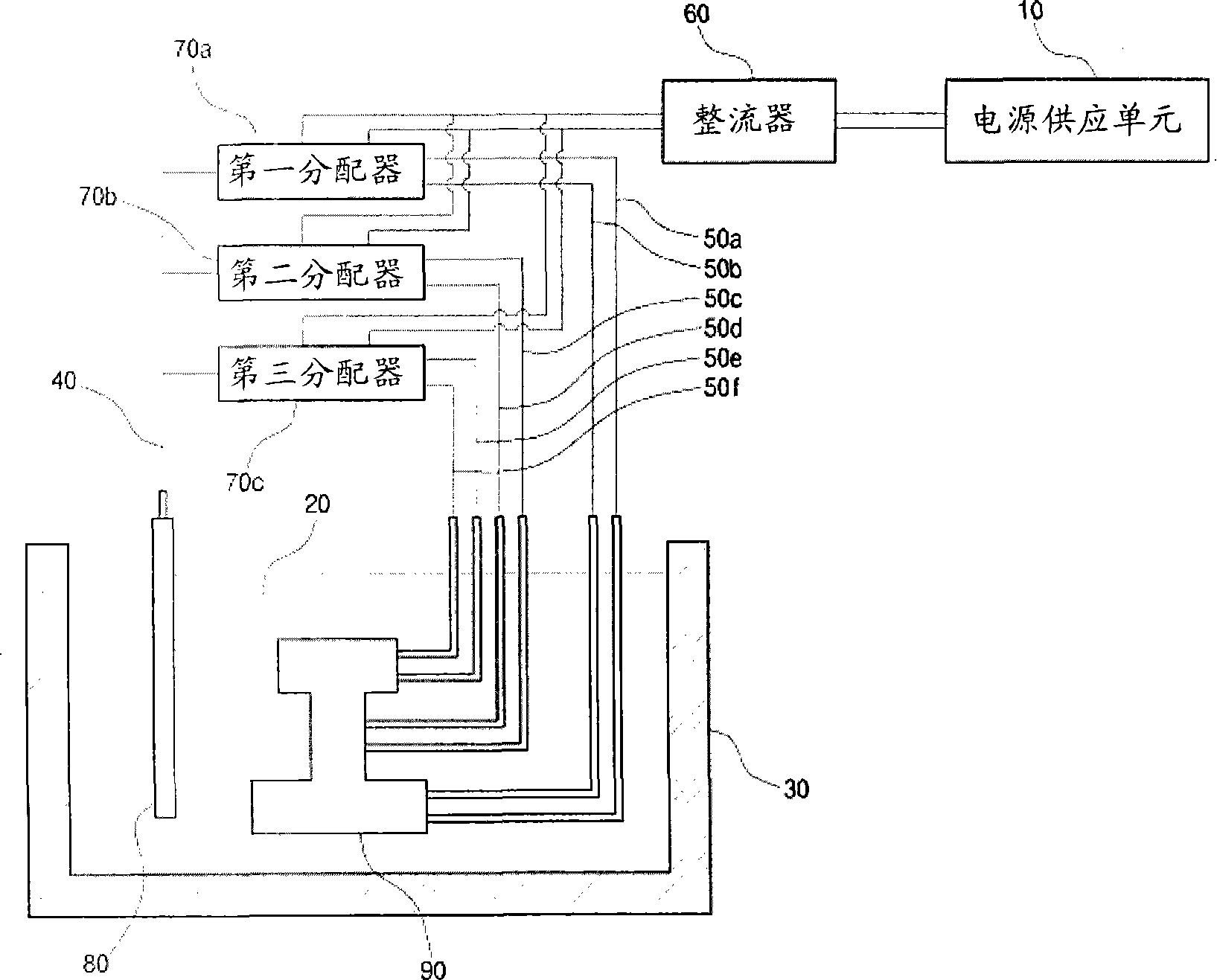

[0079] Below, refer to image 3 The first embodiment of the gold plating process of the electroplating device provided by the present invention as described above will be described.

[0080] First, when gold is plated on the surface of the metal 80 for gold plating, a surface treatment process is performed in order to improve the quality of gold plating. Here, the surface treatment process consists of a process of removing a contamination layer and rust on the surface of the metal for gold plating 80 formed by corrosion, a process of washing with water, and the like.

[0081] Next, nickel plating 80a is performed on the object to be electrolyzed 90 . The first distributor 70a divides the direct current (DC) current provided by the rectifier 60 and supplies it to the first positive electrode 40a and the first and second negative electrodes (50a, 50b). That is, assuming that the direct current (DC) current supplied by the rectifier 60 is 300 amperes, the first distributor 70 a...

no. 2 example

[0091] Below, refer to Figure 4The second embodiment of the gold plating process of the electroplating device provided by the present invention as described above will be described.

[0092] First, when the surface of the gold-plating metal 80 is gold-plated, the surface treatment process for improving the quality of the gold-plating is the same as that of the first embodiment. Here, the surface treatment process goes through a rust removal and water washing process of the surface of the contaminated metal for plating 80 .

[0093] In the next step, nickel plating 80a is implemented on the object to be electrolyzed 90: the first distributor 70a distributes the direct current (DC) current provided by the rectifier 60 and provides it to the first positive electrode 40a and the first and second negative electrodes (50a , 50b). That is, assuming that the direct current (DC) current provided by the rectifier 60 is 30 amperes, the first distributor 70 a supplies a direct current ...

no. 3 example

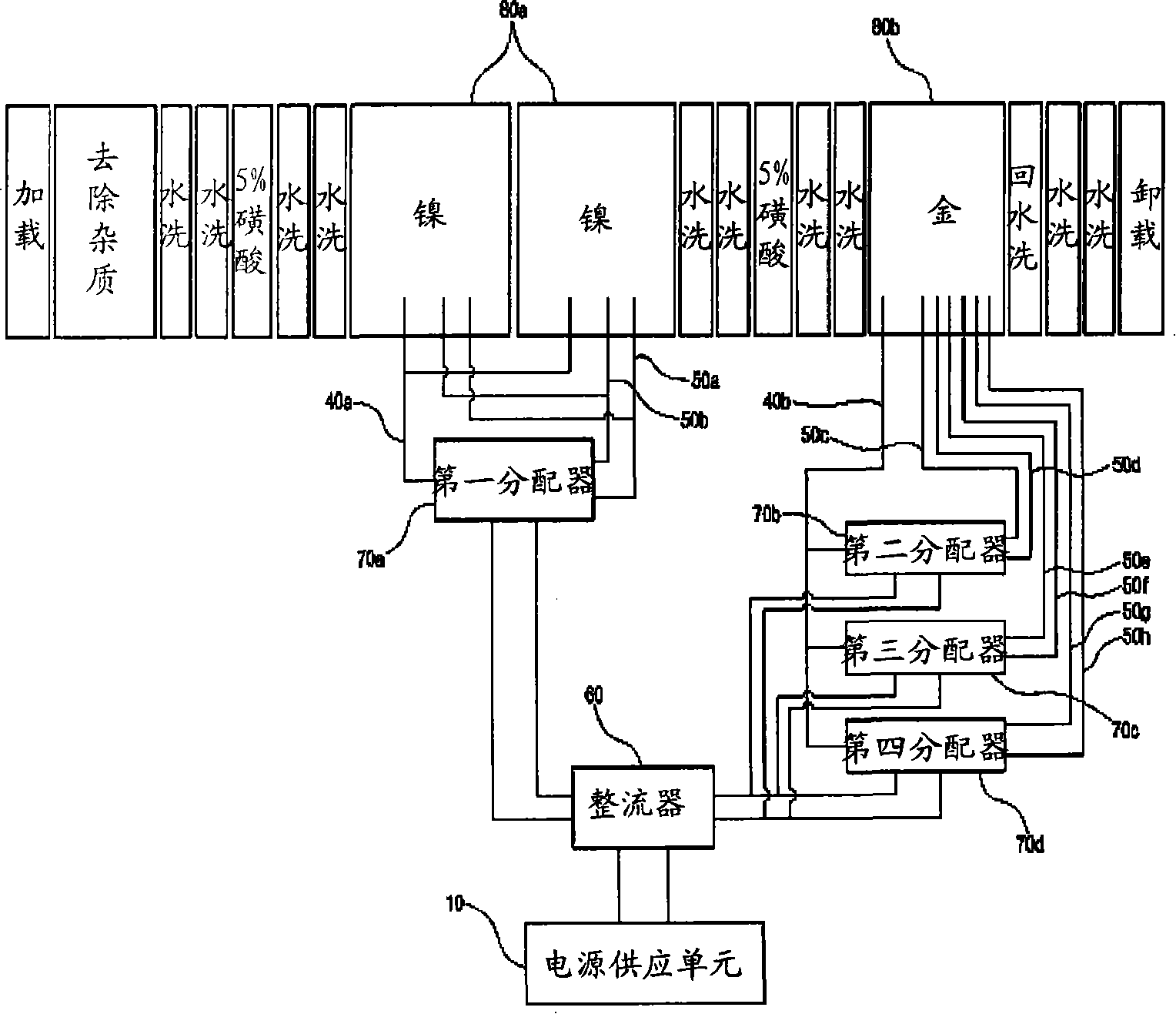

[0103] Below, refer to Figure 5 The third embodiment of the gold plating process of the electroplating device provided by the present invention as described above will be described.

[0104] First, when the surface of the metal 80 for gold plating is gold-plated, a surface treatment process is implemented in order to improve the quality of the gold plating. Here, the surface treatment process consists of a process of removing the contamination layer and rust formed on the surface of the metal 80 for plating, and a degreasing process of washing with water or removing oil.

[0105] In the next step, the process of nickel plating 80a is implemented on the object to be electrolyzed 90: the first to fourth distributors (70a, 70b, 70c, 70d) distribute the direct current (DC) current provided by the rectifier 60, and provide it to the first to fourth distributors (70a, 70b, 70c, 70d) Fourth positive electrodes (40a, 40b, 40c, 40d) and first to eighth negative electrodes (50a, 50b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com