Flue fog drip test method

A test method and droplet technology, applied in measuring devices, using differential pressure to measure fluid velocity, instruments, etc., can solve problems such as large errors and large experimental errors, and achieve the effect of accurate measurement results and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

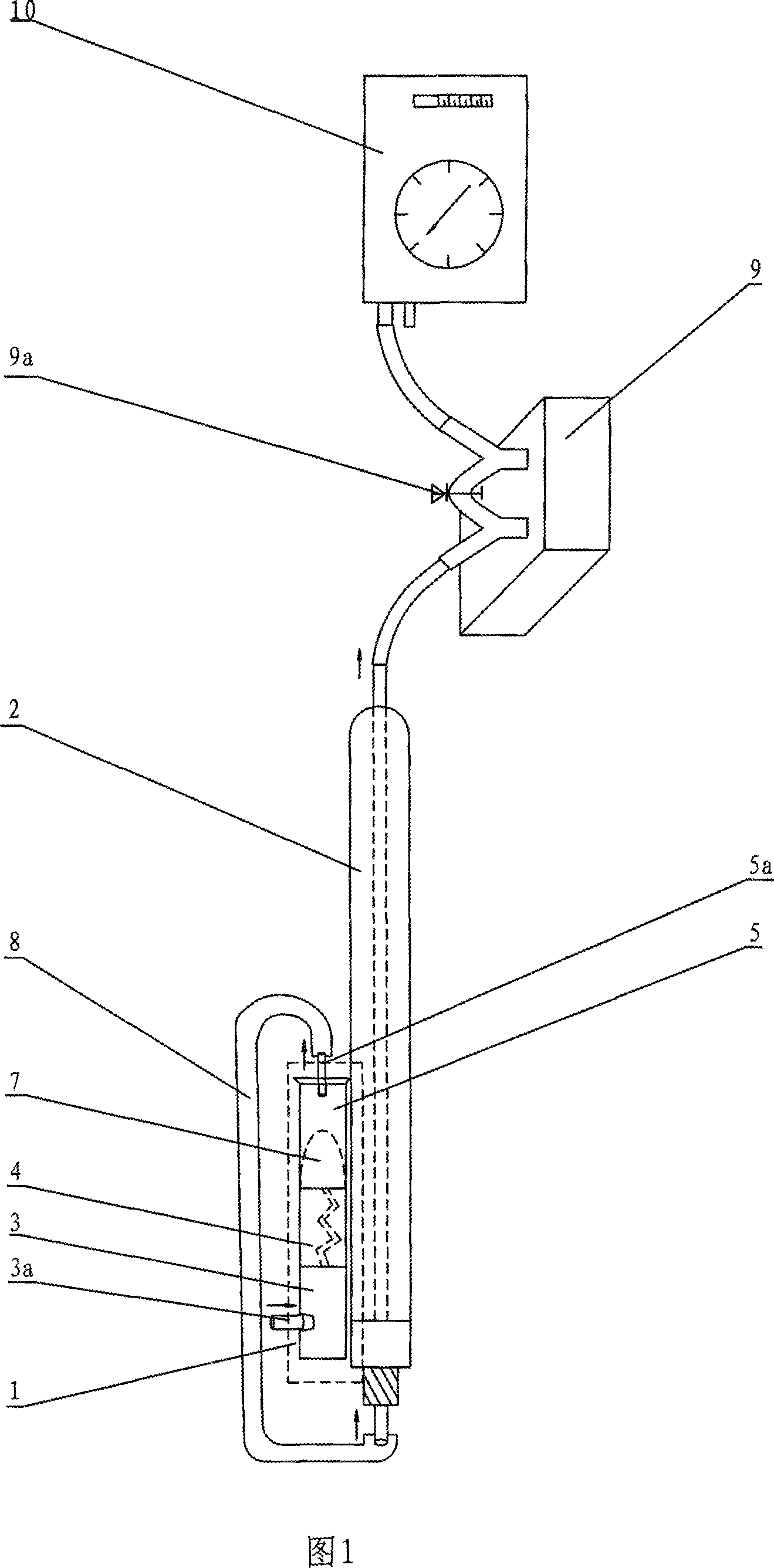

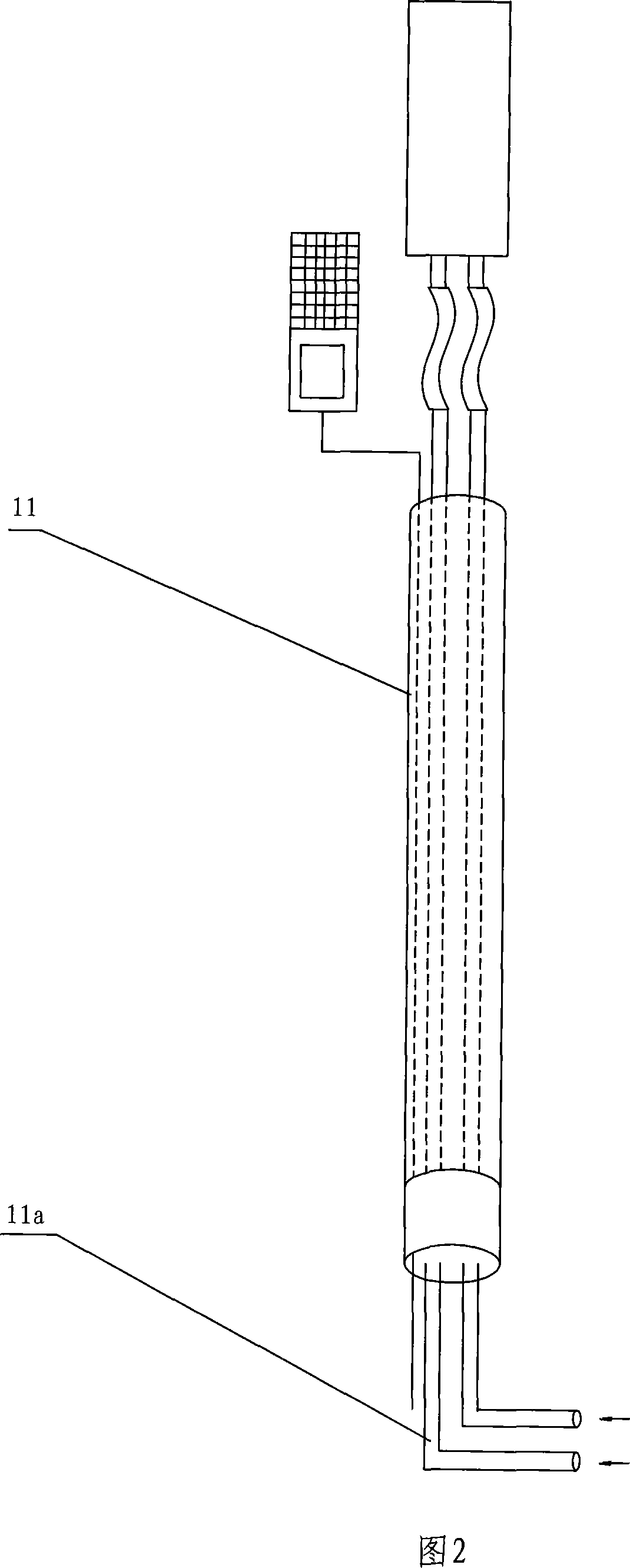

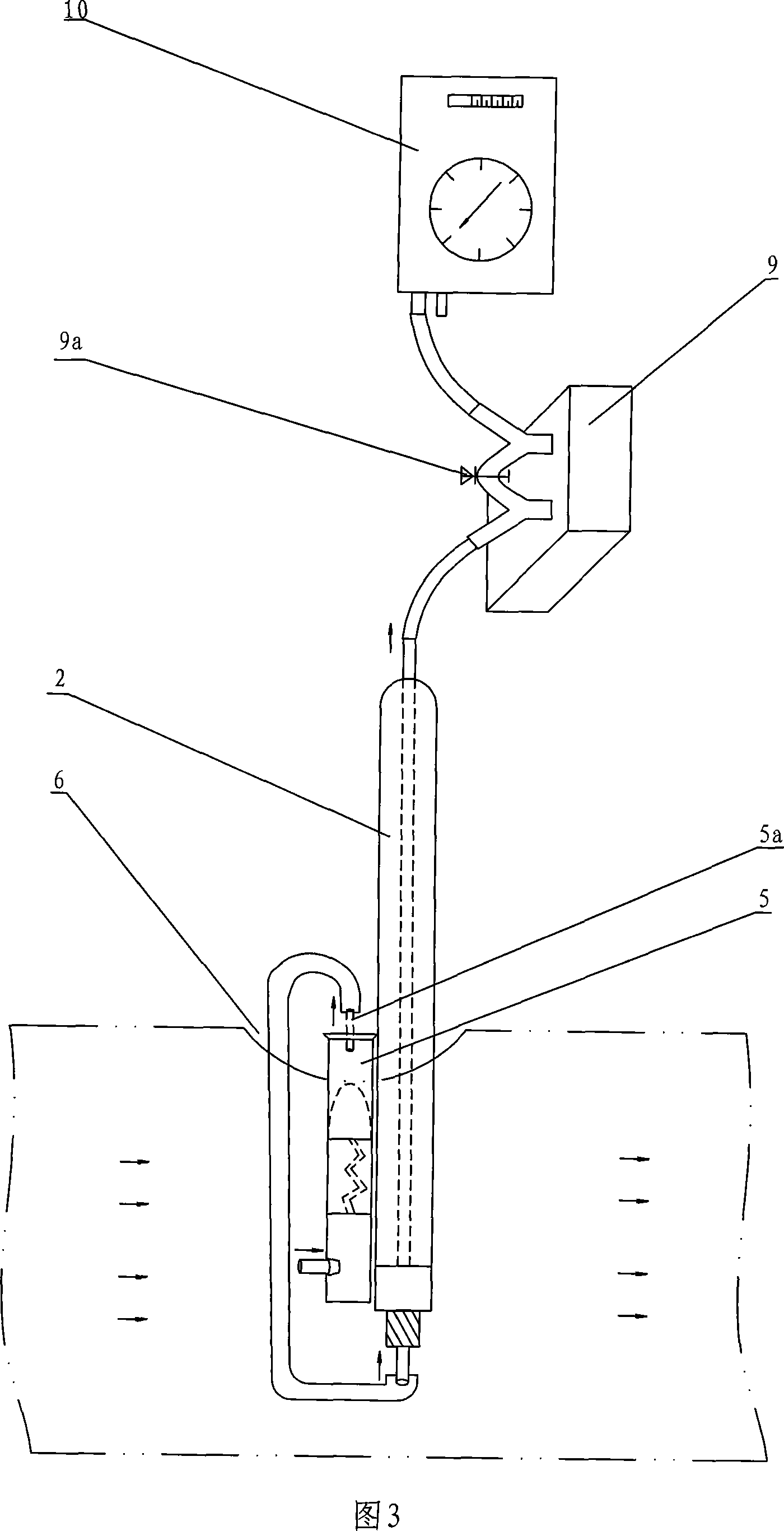

[0032] Please refer to Figure 1, Figure 2, Figure 3, and Figure 4 for the test method of droplets in flue gas, and proceed as follows:

[0033] Step 1, set the droplet sampling system, the droplet sampling system includes a droplet collection device 1, a sampling tube 2, the droplet collection device 1 is cylindrical, consisting of an upper round tube 5, a middle round tube 4, a lower round tube 3 connected components, the two ends of the middle circular tube 4 are closed, and a spiral condenser tube 4a connecting the upper and lower circular tubes 5 and 3 is arranged in the middle, and the upper end of the middle circular tube 4 is covered with a cylindrical filter paper 7, and the upper end of the upper circular tube 4 The upper end of the cylinder 5 is closed and a flue gas output pipe 5a protrudes from it. The lower end of the lower cylinder 3 is sealed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com