System for production of solid modified sulfur products

A technology for manufacturing systems and solidified bodies, applied in the fields of sulfur compounds, manufacturing tools, inorganic chemistry, etc., and can solve problems such as difficult melting and injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

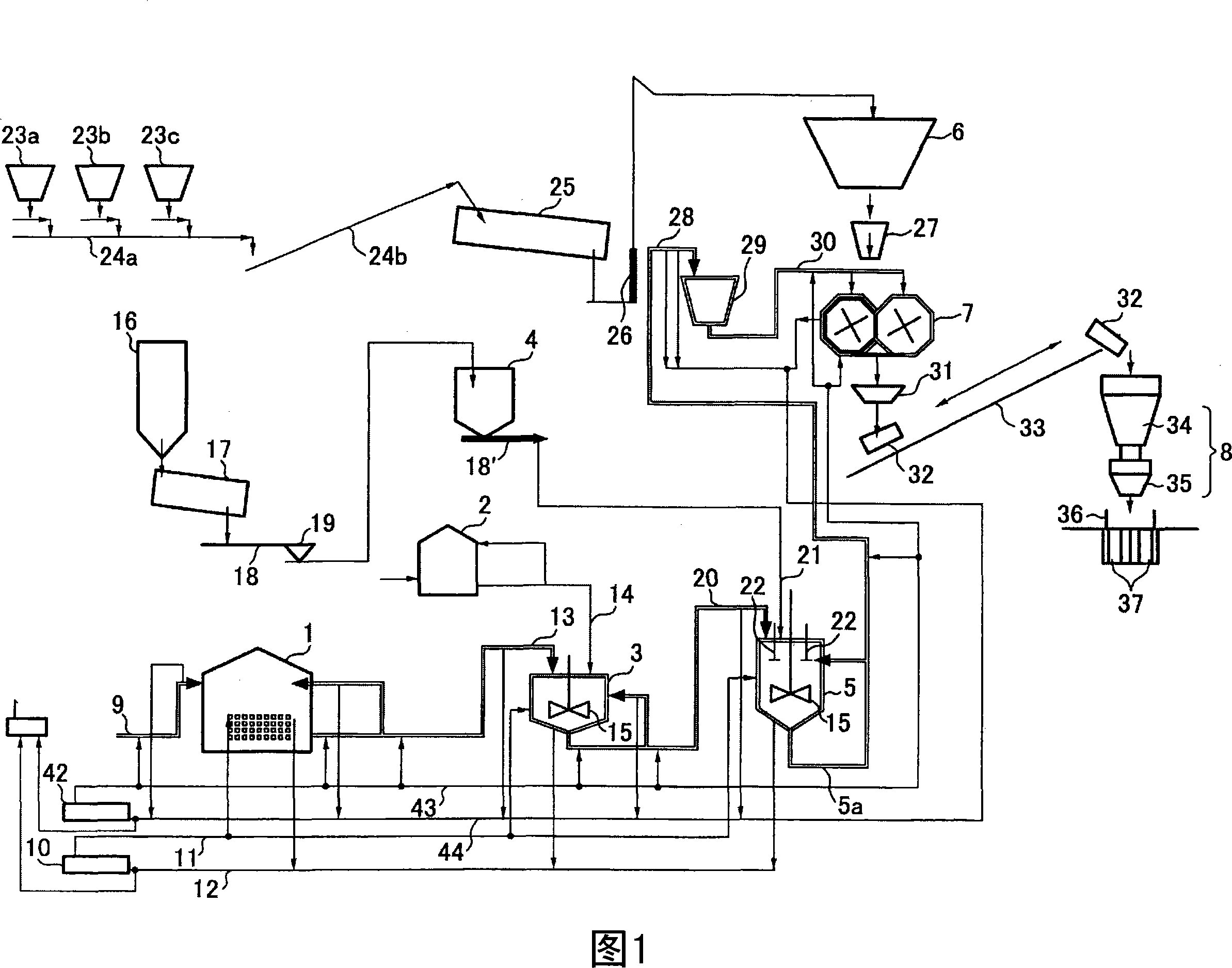

[0048] FIG. 1 is a diagram showing an embodiment of a modified sulfur cured body production system of the present invention. The modified sulfur cured body manufacturing system is used to manufacture modified sulfur modified with a sulfur modifier as a binder to solidify aggregates that can be used as materials for civil engineering or construction, and can be used as non-hazardous materials. Sulfur solidified body, which includes molten sulfur tank 1, sulfur modifier tank 2, modified sulfur manufacturing tank 3, fine aggregate heating storage bin 4, modified sulfur intermediate material tank 5, coarse aggregate heating storage Bin 6, mixing device 7, injection device 8.

[0049]The molten sulfur tank 1 accommodates molten sulfur therein and heats the contents (molten sulfur) inside to a predetermined temperature (for example, 119° C.) or higher. Sulfur is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com