A method for preparing a superhydrophobic lithium aluminum hydrotalcite coating on the surface of an aluminum alloy porous oxide film

A technology of porous oxide film and aluminum alloy surface, applied in the direction of surface reaction electrolytic coating, metal material coating process, coating, etc., can solve the problems of difficult control of the reaction process, unfavorable popularization and application, and low production efficiency, and achieve the goal of reaction The effect of short time, easy promotion and application, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

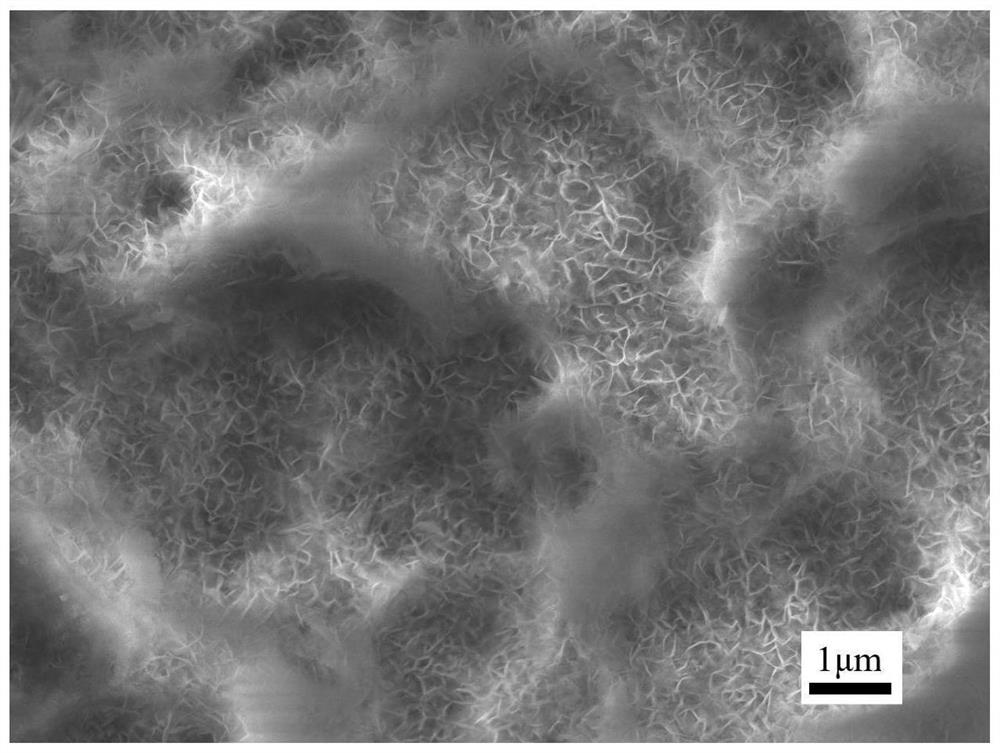

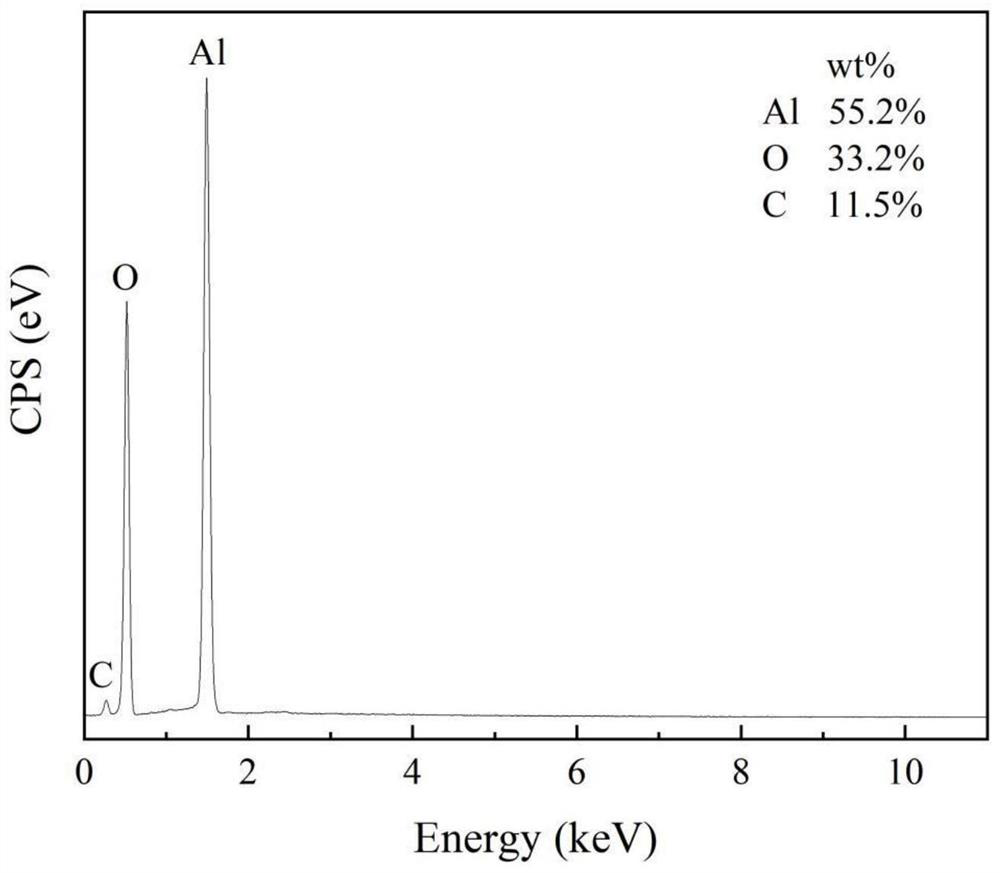

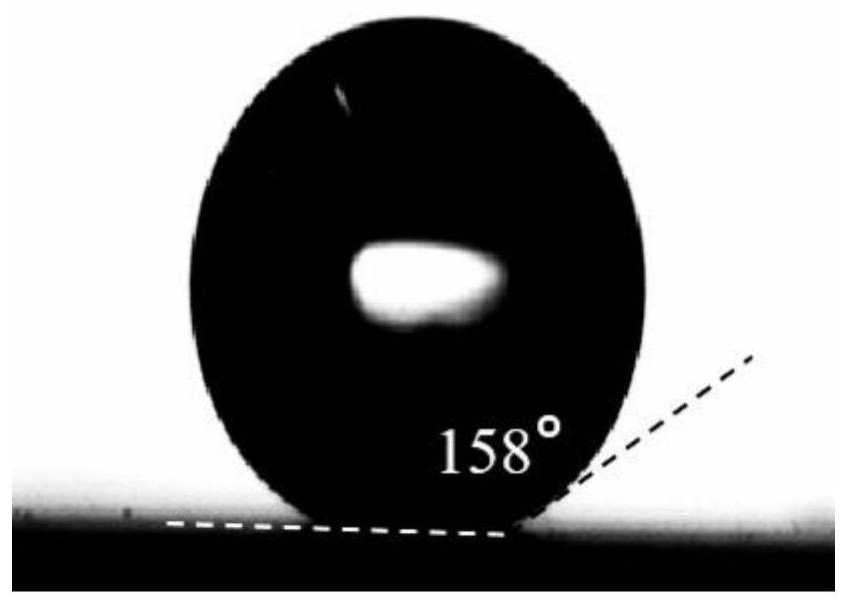

Image

Examples

Embodiment 1

[0022] (1) Aluminum alloy surface pretreatment: The surface of the 6063 aluminum alloy sample with a size of 40mm×20mm×3mm was polished to light with 240#, 400#, 600#, 1000#, 1500#, 2000# silicon carbide sandpaper in sequence, Clean the surface of the sample with absolute ethanol, then ultrasonically clean it in deionized water and absolute ethanol for 10 minutes to remove surface impurities and oil stains, and then dry it with cold air for later use;

[0023] (2) Aluminum alloy surface anodic oxidation treatment: prepare 20mL of alkaline washing liquid containing 0.5mol / LNaOH and 100mL of electrolyte containing 0.5mol / L sulfuric acid and 0.06mol / L adipic acid; The aluminum alloy sample was washed with the prepared NaOH solution for 2 minutes, rinsed with deionized water for 15 seconds, and then used as the anode, and the graphite sheet with a size of 40mm×20mm×3mm was used as the cathode, and anodized at an oxidation voltage of 15V for 20 minutes, and the distance between the ...

Embodiment 2

[0027] (1) Aluminum alloy surface pretreatment: The surface of the 6063 aluminum alloy sample with a size of 40mm×20mm×3mm was polished to light with 240#, 400#, 600#, 1000#, 1500#, 2000# silicon carbide sandpaper in sequence, Clean the surface of the sample with absolute ethanol, then ultrasonically clean it in deionized water and absolute ethanol for 10 minutes to remove surface impurities and oil stains, and then dry it with cold air for later use;

[0028](2) Aluminum alloy surface anodic oxidation treatment: prepare 20mL of alkaline washing solution containing 0.5mol / LNaOH and 100mL of electrolyte solution containing 0.3mol / L sulfuric acid and 0.04mol / L adipic acid; The aluminum alloy sample was washed with the prepared NaOH solution for 2 minutes, rinsed with deionized water for 15 seconds, and then used as the anode, and the graphite sheet with a size of 40mm×20mm×3mm was used as the cathode, and anodized at an oxidation voltage of 10V for 15 minutes, and the distance be...

Embodiment 3

[0032] (1) Aluminum alloy surface pretreatment: The surface of the 6063 aluminum alloy sample with a size of 40mm×20mm×3mm was polished to light with 240#, 400#, 600#, 1000#, 1500#, 2000# silicon carbide sandpaper in sequence, Clean the surface of the sample with absolute ethanol, then ultrasonically clean it in deionized water and absolute ethanol for 10 minutes to remove surface impurities and oil stains, and then dry it with cold air for later use;

[0033] (2) Aluminum alloy surface anodic oxidation treatment: prepare 20mL of alkaline washing solution containing 0.5mol / LNaOH and 100mL of electrolyte solution containing 0.7mol / L sulfuric acid and 0.10mol / L adipic acid; The aluminum alloy sample was washed with the prepared NaOH solution for 2 minutes, rinsed with deionized water for 15 seconds, and then used as the anode, and the graphite sheet with a size of 40mm×20mm×3mm was used as the cathode, and anodized at an oxidation voltage of 20V for 25 minutes, and the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com