Curable resin composition and cured object thereof

A curable resin and composition technology, applied in instruments, photosensitive materials for optomechanical equipment, optics, etc., can solve the problems of electrical corrosion, poor operation of electronic machines, bursting, etc., and achieve less gasification components, Realization of low linear expansion and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] Next, the present invention will be specifically described below by showing examples and comparative examples of the present invention, but the present invention is not limited to the following examples. In addition, "parts" and "%" mean "parts by mass" and "% by mass" unless otherwise specified.

Synthetic example 1

[0075] (synthesis of carboxyl group-containing copolymer resin A)

[0076] 900 g of diethylene glycol dimethyl ether, and 21.4 g of tert-butyl peroxide 2-ethylhexanoate were added to a 2-liter separable flask with a stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen inlet tube Esters [PERBUTYL O manufactured by NOF Corporation], after heating up to 90°C, 309.9g of methacrylic acid, 116.4g of methyl methacrylate, and 109.8g of lactones represented by general formula (I) were converted into 2-Hydroxyethyl methacrylate [Placcel FM1 manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.] was added dropwise with 21.4 g of bis(4-tert-butylcyclohexyl) peroxydicarbonate [PEROYL TCP manufactured by NOF Corporation] In diethylene glycol dimethyl ether, aging was further performed for 6 hours to obtain a carboxyl group-containing copolymer resin (A) solution. The reaction was carried out under nitrogen atmosphere.

[0077] Next, 363.9 g of 3,4-epoxycyclohexylmethyl acryla...

Embodiment 1~4 and comparative example 1

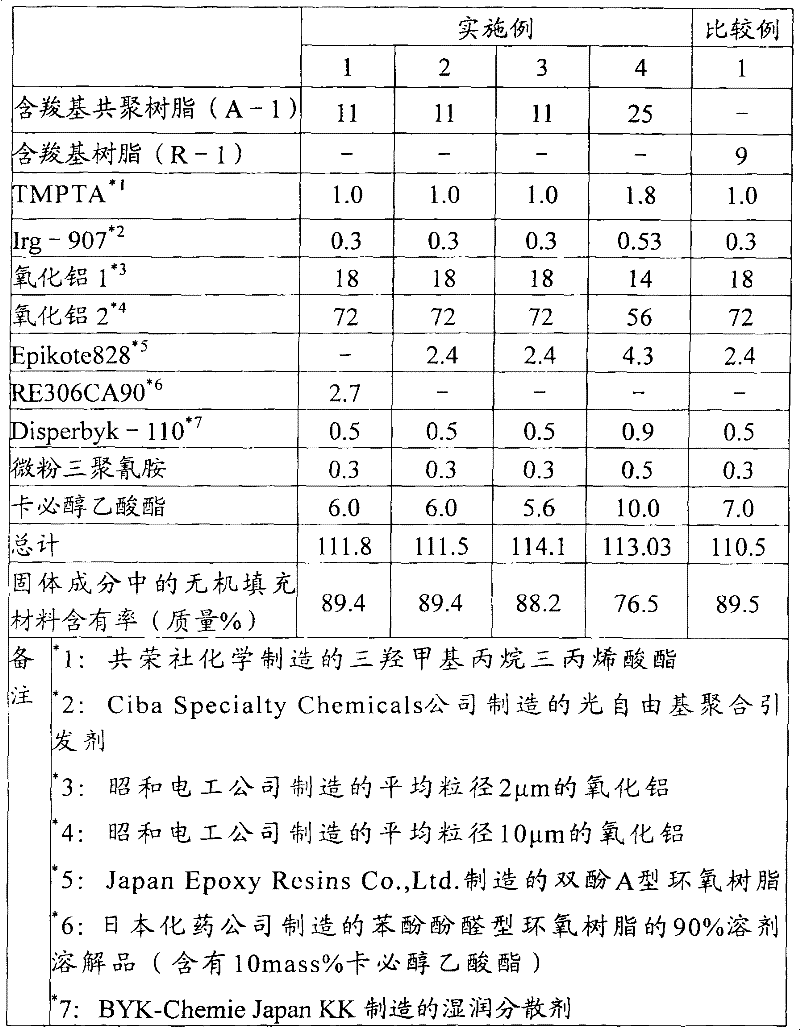

[0081] The ingredients shown in Table 1 using the A-1 varnish and the R-1 varnish obtained in the above synthesis example were kneaded with a three-roll mill to obtain a curable resin composition. Table 2 shows the property evaluation results of each curable composition.

[0082] Table 1

[0083]

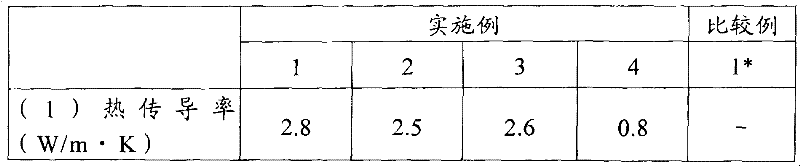

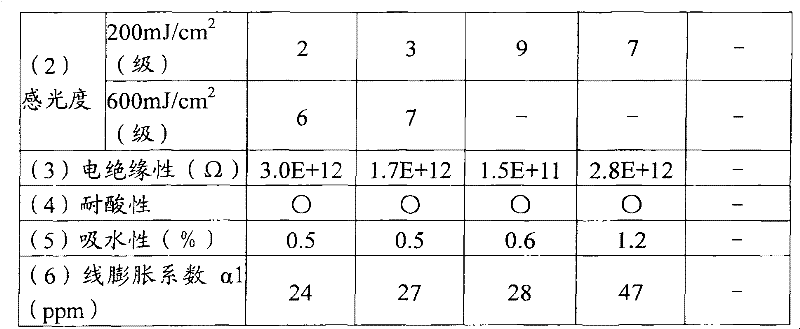

[0084] Table 2

[0085]

[0086]

[0087] * : Inking failed at high filling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com