Thermally conductive and insulating composite material and its preparation method and application

A technology of heat conduction insulation and composite materials, applied in the field of composite materials, can solve the problems of large interface thermal resistance, phonon scattering, sacrifice material mechanical properties, etc., and achieve the effects of efficient heat transfer, high thermal conductivity, and reduced contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

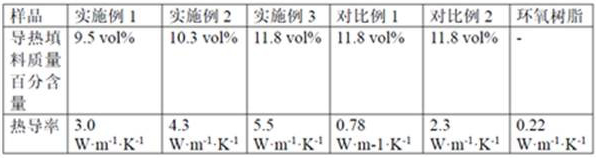

Examples

preparation example Construction

[0037] In another aspect of the present invention, a method for preparing the thermally conductive and insulating composite material is provided, which includes the following steps:

[0038] S10, providing wood sponge and boron nitride nanosheets;

[0039] S20, dissolving the boron nitride nanosheets in water to form a boron nitride solution, and immersing the wood sponge in the boron nitride solution for loading to obtain a boron nitride-wood sponge hybrid filler;

[0040] S30, mixing the resin matrix with the boron nitride-wood sponge hybrid filler, and curing to obtain a thermally conductive and insulating composite material.

[0041] In some embodiments, the preparation method of the wood sponge comprises:

[0042] S12, cutting and chemically treating the natural wood according to the growth method, wherein the chemical treatment includes a step of selectively removing lignin and hemicellulose components in the cell wall of the natural wood and a step of freeze-drying;

[...

Embodiment 1

[0059] 1. Preparation of wood sponge

[0060] (1) Cut the balsa wood into 2cm*2cm*2cm blocks along the growth direction, immerse the blocks in acetic acid-sodium acetate buffer solution containing 5 wt% sodium hypochlorite, pH 4.6, and heat to 100°C for reaction 6h for delignification treatment.

[0061] (2) Immerse the delignified wood in a solution containing 8wt% NaOH, and react at 80°C for 8 h to remove hemicellulose in the wood.

[0062] (3) Soak the wood after lignin and hemicellulose has been removed with ethanol-water solution repeatedly to remove the remaining chemical substances inside, then freeze the wood at -20°C for 10 hours, and then freeze it at -56°C Dry for 40 hours to get wood sponge.

[0063] 2. Preparation of boron nitride nanosheets

[0064] Mix 3g of hexagonal boron nitride with 325 meshes and 90g of urea, and use a planetary ball mill to mill at a speed of 300rpm for 24 hours. The powder obtained by ball milling is dissolved in water, subjected to su...

Embodiment 2

[0072] 1. Preparation of wood sponge

[0073] (1) Cut the balsa wood into 2cm*2cm*2cm blocks along the growth direction, immerse the blocks in acetic acid-sodium acetate buffer solution containing 5 wt% sodium hypochlorite, pH 4.6, and heat to 100°C for reaction 6h for delignification treatment.

[0074] (2) Immerse the delignified wood in a solution containing 8wt% NaOH, and react at 80°C for 8 h to remove hemicellulose in the wood.

[0075] (3) Soak the wood after lignin and hemicellulose has been removed with ethanol-water solution repeatedly to remove the remaining chemical substances inside, then freeze the wood at -20°C for 10 hours, and then freeze it at -56°C Dry for 40 hours to get wood sponge.

[0076] 2. Preparation of boron nitride nanosheets

[0077] Mix 3g of hexagonal boron nitride with 325 meshes and 90g of urea, and use a planetary ball mill to mill at a speed of 300rpm for 24 hours. The powder obtained by ball milling is dissolved in water, subjected to su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com