Separating bag material fungus stick mincing machine

A separation type and grinder technology, applied in plastic recycling, recycling technology, grain processing and other directions, can solve the problems of high labor intensity, low efficiency and high labor cost, and achieve high production efficiency, simple structure and convenient moving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

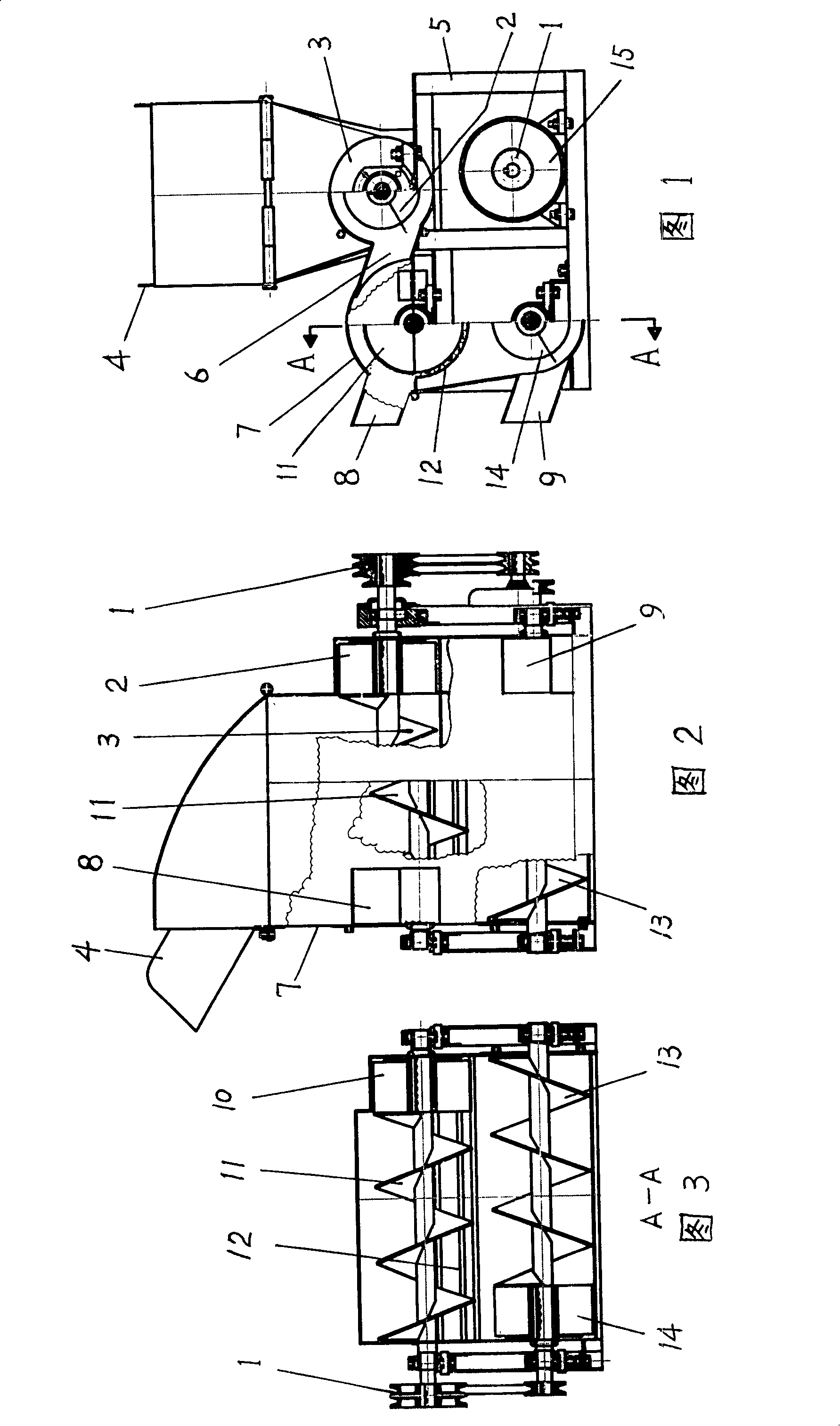

[0014] Can know with reference to accompanying drawing 1,2,3, concrete parts and components of the present invention comprise: 1~belt transmission mechanism, 2~crush and throw away material blower blower blade, 3~crush conveying hinge dragon, 4~feed hopper, 5~ Frame (frame), 6~inner discharge port, 7~casing, 8~waste film discharge port, 9~cultivation material (crushed material) discharge port, 10~waste film rejection blower blade, 11~ Separation conveying hinge dragon, 12~strip semi-circumferential screen cloth (also known as arc bottom screen cloth), 13~material conveying hinge dragon, 14~material fan fan blades, 15~motor. The specific connection relationship of each component is as follows: The crushing and conveying separation mechanism is composed of three hinges installed on the frame in sequence, that is, the crushing and conveying hinge 3 for crushing bacteria sticks, and the separation of waste plastic film. The separation conveying hinge dragon 11 and the material (di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com