Mold structure and ejection shaping method

A mold and master mold technology, applied in the field of mold structure and injection molding, can solve the problems of product strength reduction, consumer purchase willingness reduction, product size variation, etc., to improve strength and size accuracy, improve fluidity and integration The effect of avoiding surface depression and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

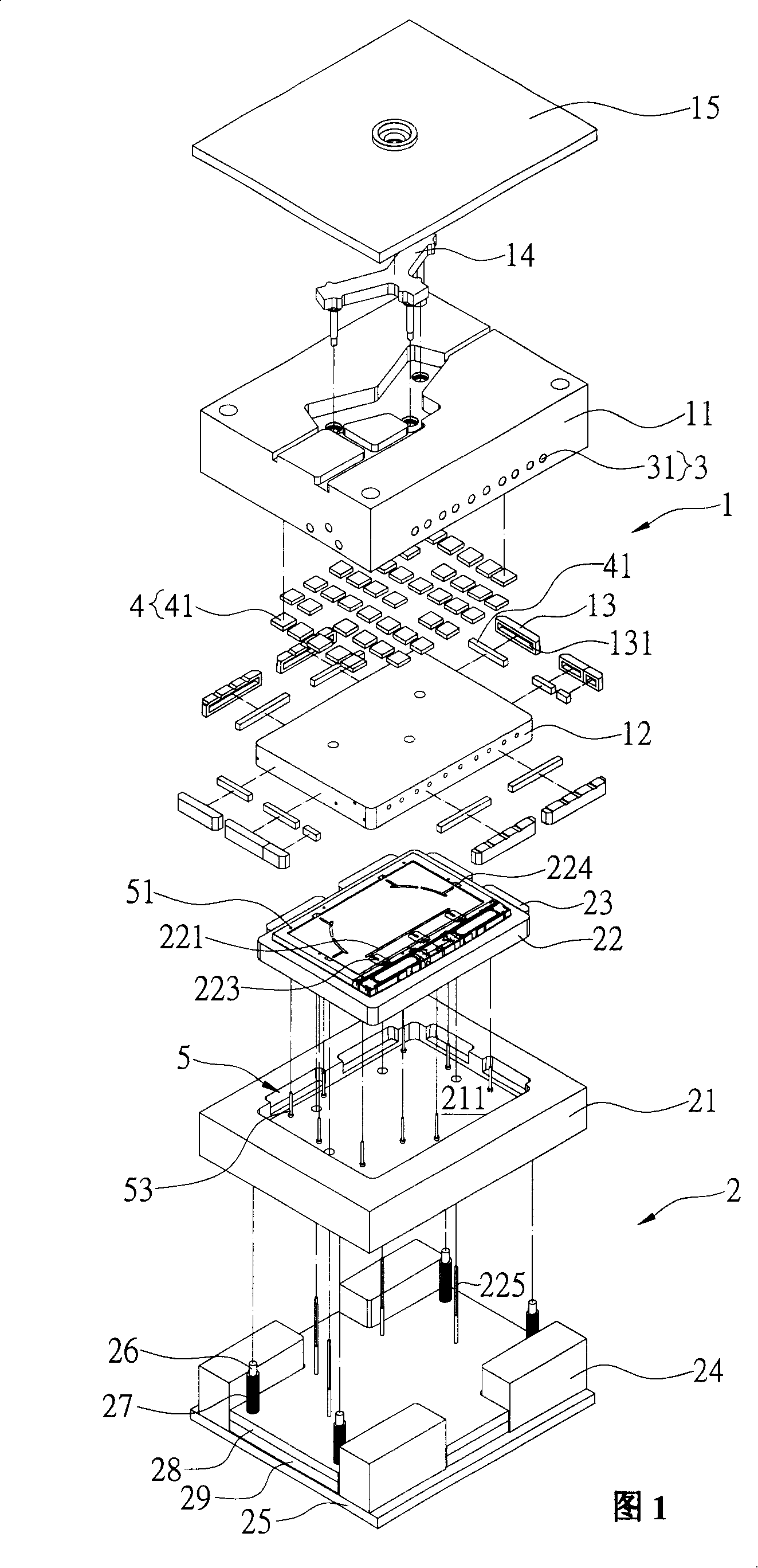

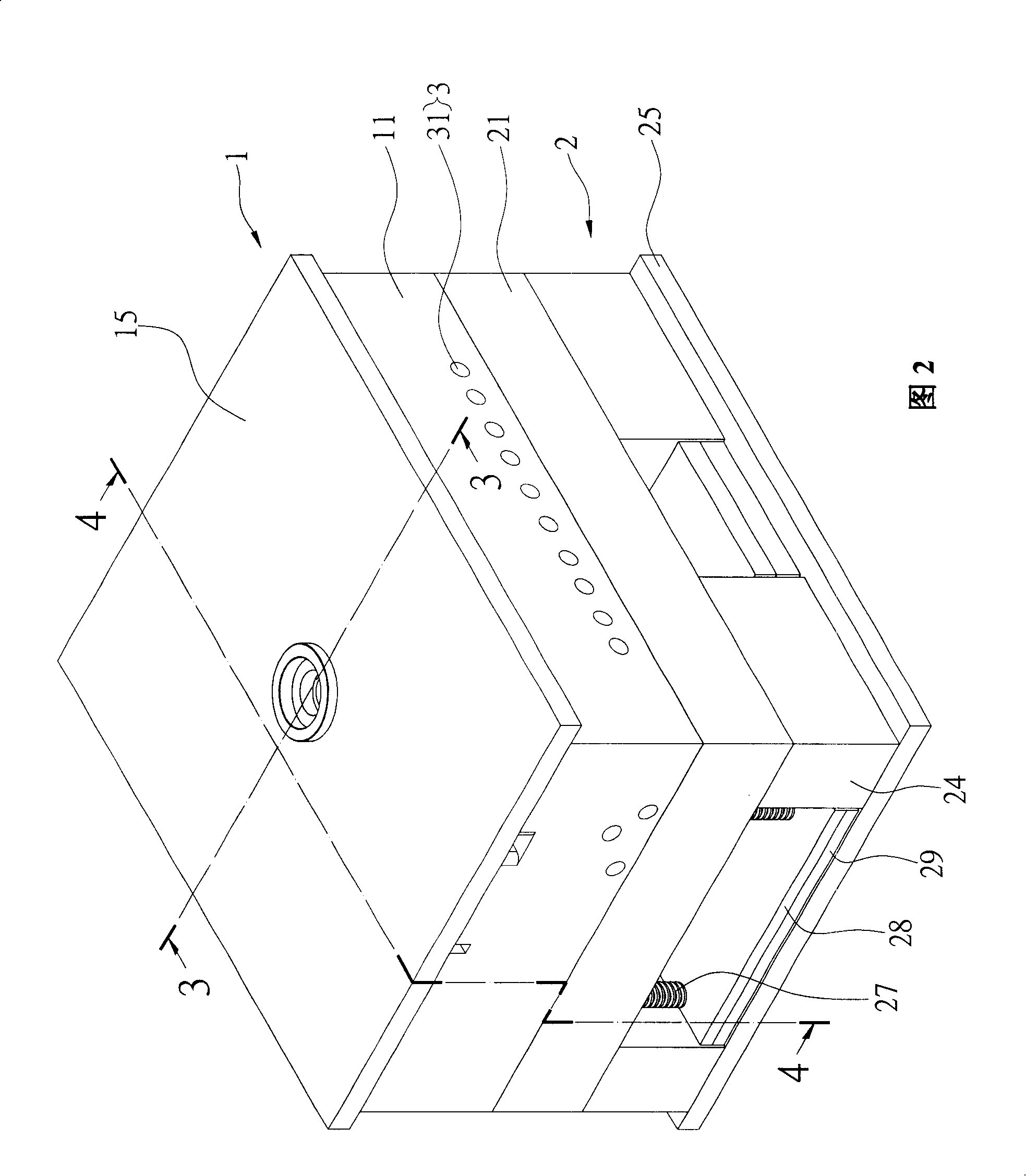

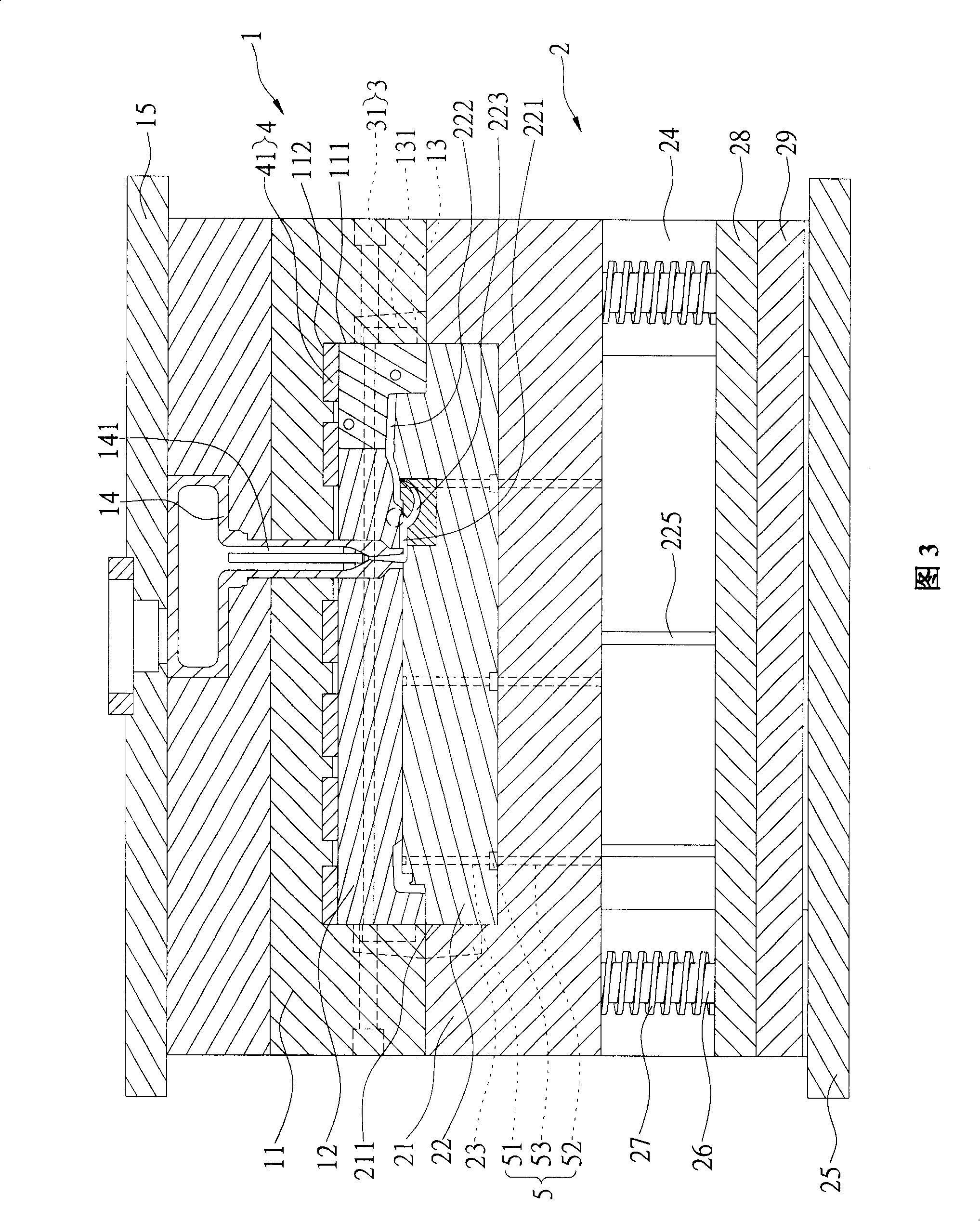

[0055] Please refer to Figures 1 to 4, the present invention provides a mold structure, in this embodiment, the mold structure is used for injection molding a square screen frame trim, the mold structure includes a female module 1. A male module 2 , a heating unit 3 , a heat insulation unit 4 and a guiding unit 5 .

[0056] The female module 1 has a female template 11, a female mold core 12, a plurality of female mold core bundle blocks 13, a heat flow plate 14 and an upper fixing plate 15, and a first concave inward recess is formed on one side of the female template 11. The accommodating portion 111 , the top surface of the first accommodating portion 111 is provided with a plurality of inwardly recessed first grooves 112 . The female mold core 12 and the female mold core bundle blocks 13 are fixed in the first accommodating portion 111, and the female mold core bundle blocks 13 are fixed on the side walls around the female mold core 12 and the first Between the accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com