Fibre enhancement modifying method for polyurethane foam plastic

A foam and fiber-reinforced technology, applied in the field of fiber-reinforced modification of polyurethane foam, to achieve good performance, uniform interface, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

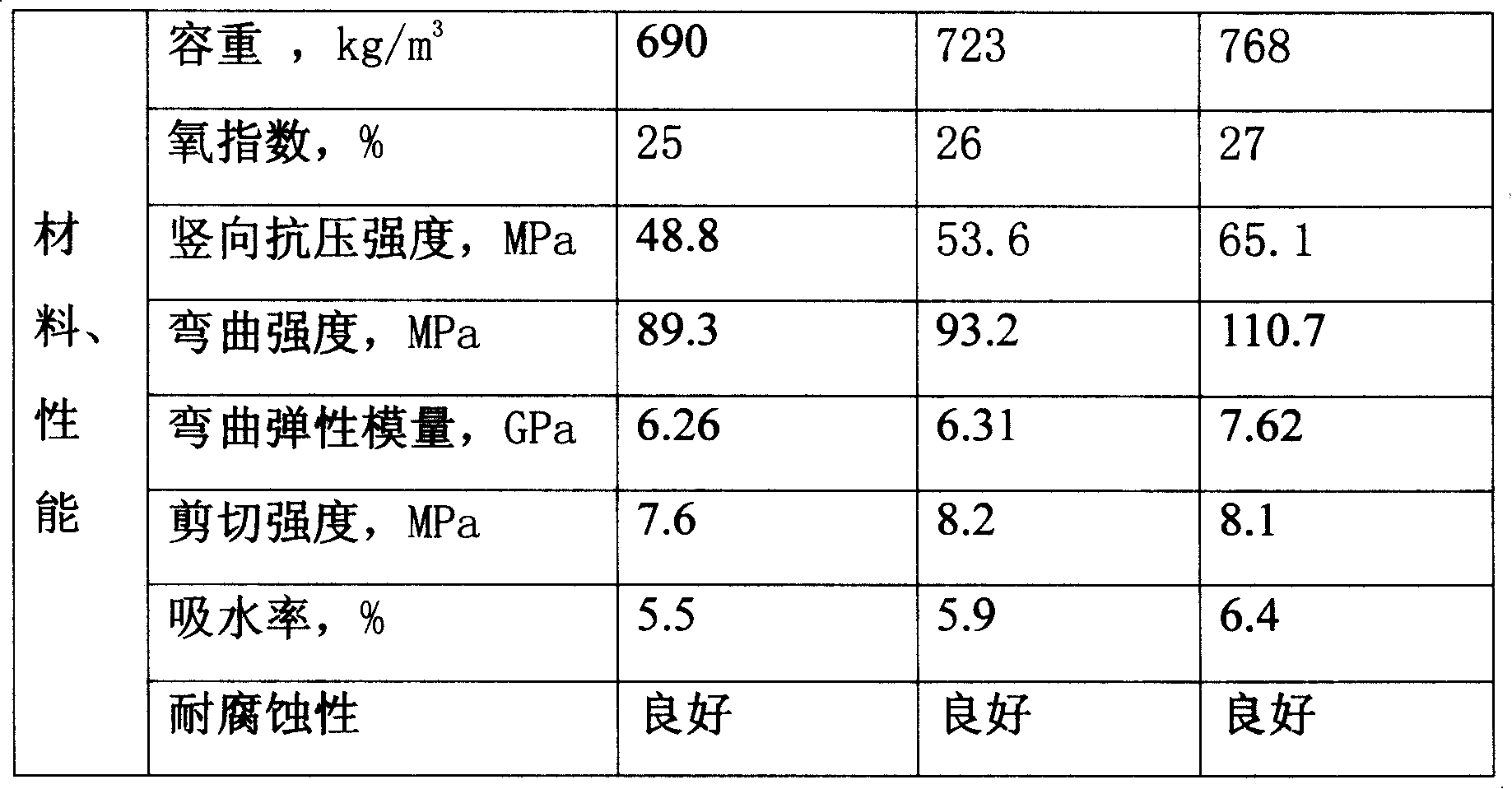

Examples

specific Embodiment approach 2

[0033] Polyether polyol 1 85, polyether polyol 2 15, catalyst 0.01, hard foam silicone oil 1, foaming agent 0.30, flame retardant 10, anti-aging agent 0.1, isocyanate 130, reinforcing material 240, using compression molding or pultrusion method, the specific method is:

[0034] 1. Compression molding is to mix the components in the formula evenly, then spray on the surface of the reinforcing fiber at a relatively fast speed, impregnate evenly, and put it into the mold for curing at room temperature;

[0035] 2. Pultrusion molding is carried out by using pultrusion equipment. After mixing the components in the formula evenly, spray it on the surface of the reinforced fiber running at a certain speed at a relatively fast speed, and enter the mold cavity after uniform impregnation for foaming, curing, forming.

specific Embodiment approach 3

[0036] Polyether polyol 1 90, polyether polyol 2 10, catalyst 0.01, hard foam silicone oil 1.5, foaming agent 0.25, flame retardant 15, antioxidant 0.1, isocyanate 150, reinforcing material 265, using compression molding or pultrusion method, the specific method is:

[0037] 1. Compression molding is to mix the components in the formula evenly, then spray on the surface of the reinforcing fiber at a relatively fast speed, impregnate evenly, and put it into the mold for curing at room temperature;

[0038] 2. Pultrusion molding is carried out by using pultrusion equipment. After mixing the components in the formula evenly, spray it on the surface of the reinforced fiber running at a certain speed at a relatively fast speed, and enter the mold cavity after uniform impregnation for foaming, curing, forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com