Dry-type chargeable vanadium cell manufacturing technique

A vanadium battery, dry-type technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of affecting the service life of the battery, the number of charging and discharging cycles, etc., achieve good electrochemical reversibility, increase energy density, increase Effect of Cycle Number and Lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

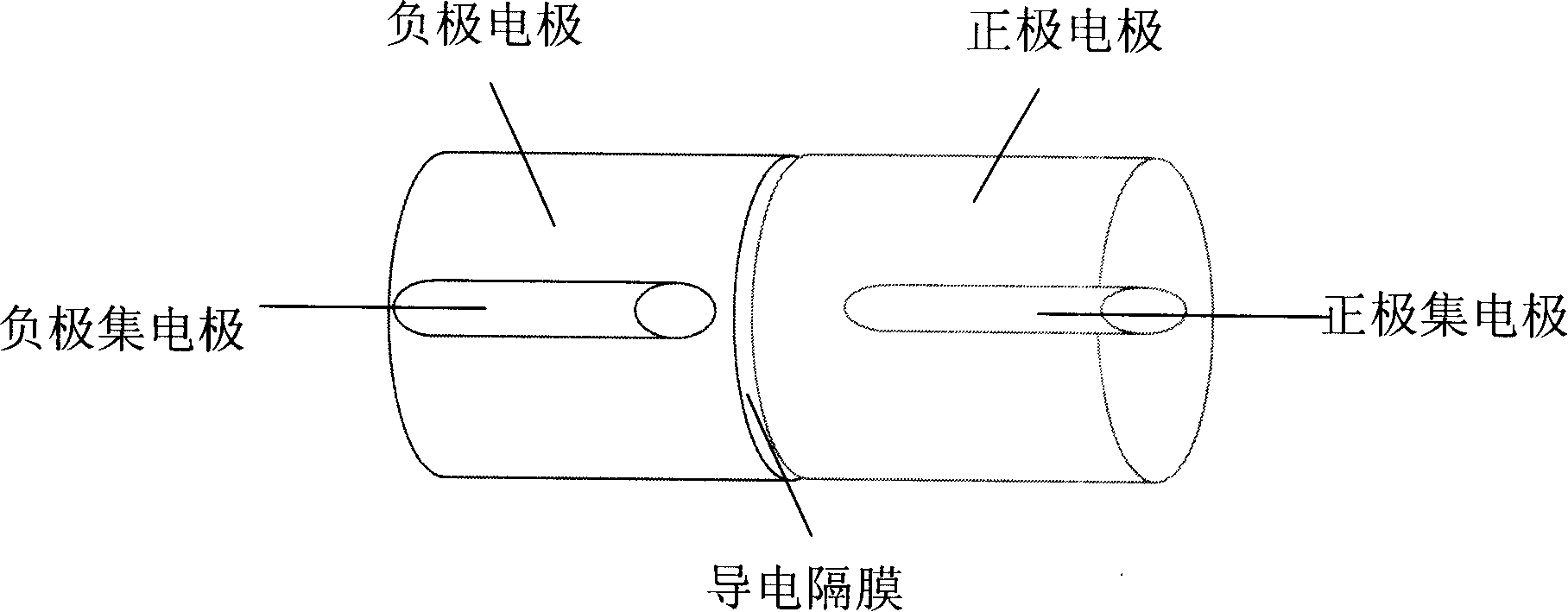

Image

Examples

Embodiment Construction

[0006] 1. 26g of a mixture of 3-valent vanadium and 4-valent vanadium sulfate (wherein 3-valent vanadium and 4-valent vanadium sulfate each account for 50%), plus 0.3 grams of sulfuric acid, 0.6 grams of lithium sulfate, 2.5 grams of graphite Powder, 1.2 grams of polyvinyl alcohol, 6 grams of water, mixed evenly, divided into two parts evenly, filled the above mixture in the mold, inserted a carbon rod collector in the middle, and made positive and negative electrodes. Conductive separators use ultra-high molecular weight polyethylene microporous membranes to make battery tests. The constant voltage charging voltage is 1.95 volts, the charging capacity is 0.3Ah, the constant resistance discharge is 0.5 ohms, the average discharging voltage is 1.45 volts, and the discharging capacity is 0.26Ah.

[0007] 2. 26g of a mixture of 3-valent vanadium and 4-valent vanadium sulfate (wherein 3-valent vanadium and 4-valent vanadium sulfate each account for 50%), plus 6.5 grams of sulfuric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com