Method for preparing organic particle

A technology of organic particles and organic materials, which is applied in the fields of organic dyes, chemical instruments and methods, and nanostructure manufacturing, and can solve problems such as changes in particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

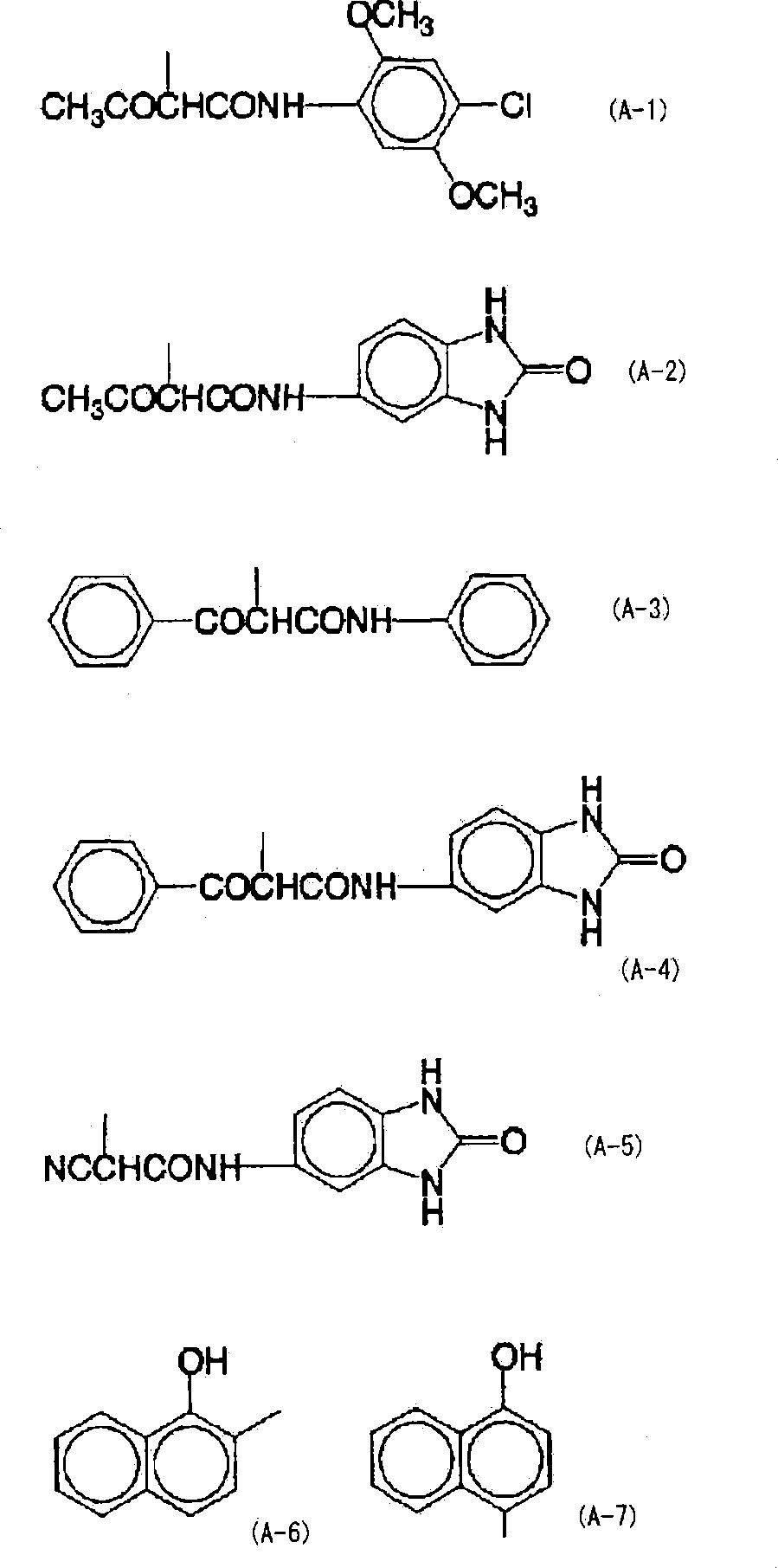

[0109] A pigment solution was prepared by dissolving 530 mg of a pigment (Pigment Red 254) and 8 ml of a 1 mol / L aqueous sodium hydroxide solution in 100 ml of 1-methyl-2-pyrrolidone. In addition, 1,000 ml of a solution containing dispersant A1 and 8 ml of 1 mol / L hydrochloric acid was prepared as a poor solvent. The amount of dispersant A1 is shown in Table 1. (In this table, the amount of the dispersant is represented by the concentration (mass %) which is the content of the dispersant in the solvent in which the dispersant is dissolved. The same applies to the following tables.)

[0110] [chemical formula 12]

[0111] Dispersant A1

[0112]

[0113] The pigment particle dispersion liquid was prepared by injecting the entirety of the pigment solution thus prepared into the poor solvent at a flow rate of 50 ml / min using a large-capacity non-pulsation pump NP-KX-500 manufactured by Nihon Seimitsu Kagaku Co., Ltd. At this time, the poor solvent was stirred at a speed of 50...

Embodiment 2

[0118] A pigment solution was prepared by dissolving 530 mg of a pigment (Pigment Red 254) and 8 ml of a 1 mol / L aqueous sodium hydroxide solution in 100 ml of 1-methyl-2-pyrrolidone. In addition, 1,000 ml of a solution containing sodium oleate and 8 ml of 1 mol / L hydrochloric acid was prepared as a poor solvent. The amount of sodium oleate is shown in Table 2.

[0119] The pigment particle dispersion liquid was prepared by injecting the entirety of the pigment solution thus prepared into the poor solvent at a flow rate of 50 ml / min using a large-capacity non-pulsation pump NP-KX-500 manufactured by Nihon Seimitsu Kagaku Co., Ltd. At this time, the poor solvent was stirred at a speed of 500 rpm with a GK-0222-10 Ramond stirrer manufactured by Fujisawa Pharmaceutical Co., Ltd., and the temperature was controlled at 1°C.

[0120] The evaluations of the primary particle size, Mv / Mn ratio, and dispersed state were performed in the same manner as in Example 1, respectively. The re...

Embodiment 3

[0124] Pigment solution was prepared by dissolving 530 mg of pigment (Pigment Red 254) and 8 ml of 1 mol / L aqueous sodium hydroxide solution and dispersant B1 in 100 ml of 1-methyl-2-pyrrolidone, wherein the amount of dispersant B1 was shown in Table 3.

[0125] [chemical formula 13]

[0126] Dispersant B1

[0127]

[0128] Separately prepare 1,000 ml of a solution containing 8 ml of 1 mol / L hydrochloric acid as a poor solvent.

[0129] The pigment particle dispersion liquid was prepared by injecting the entirety of the pigment solution thus prepared into the poor solvent at a flow rate of 50 ml / min using a large-capacity non-pulsation pump NP-KX-500 manufactured by Nihon Seimitsu Kagaku Co., Ltd. At this time, the poor solvent was stirred at a speed of 500 rpm with a GK-0222-10 Ramond stirrer manufactured by Fujisawa Pharmaceutical Co., Ltd., and the temperature was controlled at 1°C.

[0130] The evaluations of the primary particle size, Mv / Mn ratio, and dispersed stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com