Spherical silver particle, method for producing same, conductive paste, and device containing same

A manufacturing method and technology of silver particles, applied to conductive materials dispersed in non-conductive inorganic materials, transportation and packaging, metal processing equipment, etc., can solve the problem of dispersibility and storage stability decline, uneven particle size distribution of silver powder, Unable to achieve physical properties and other problems, to achieve the effect of excellent physical properties, simple process, and excellent sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

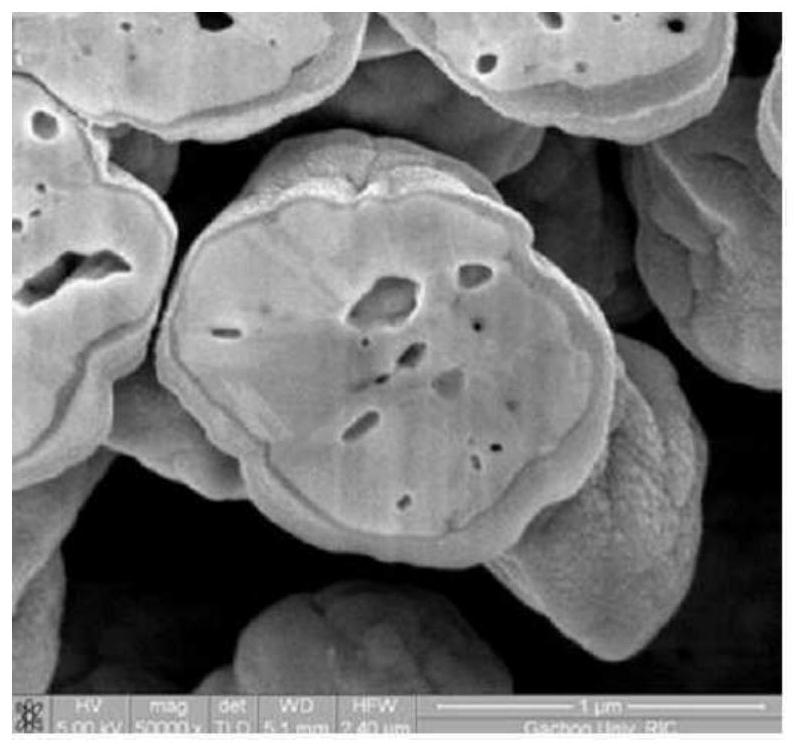

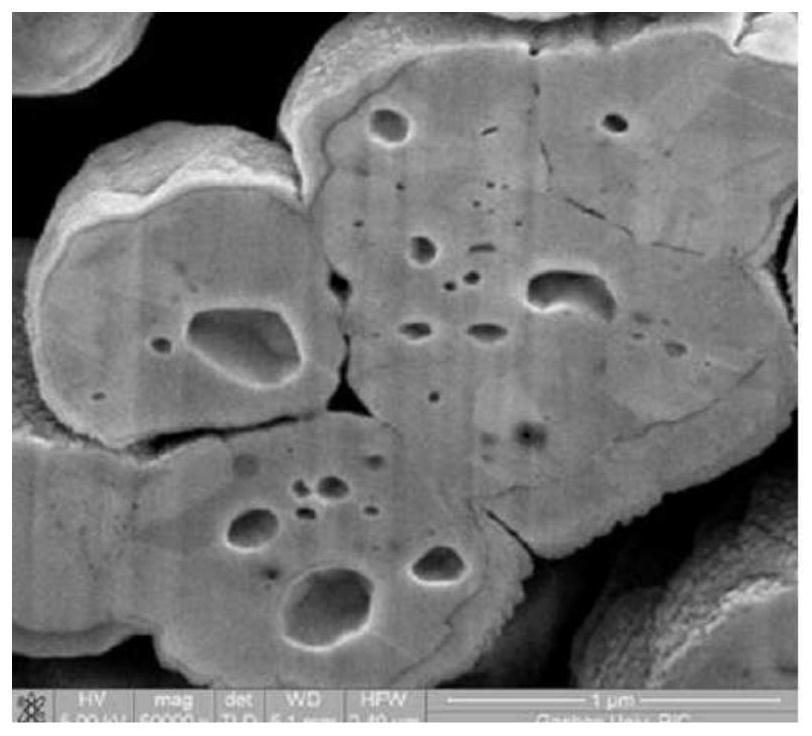

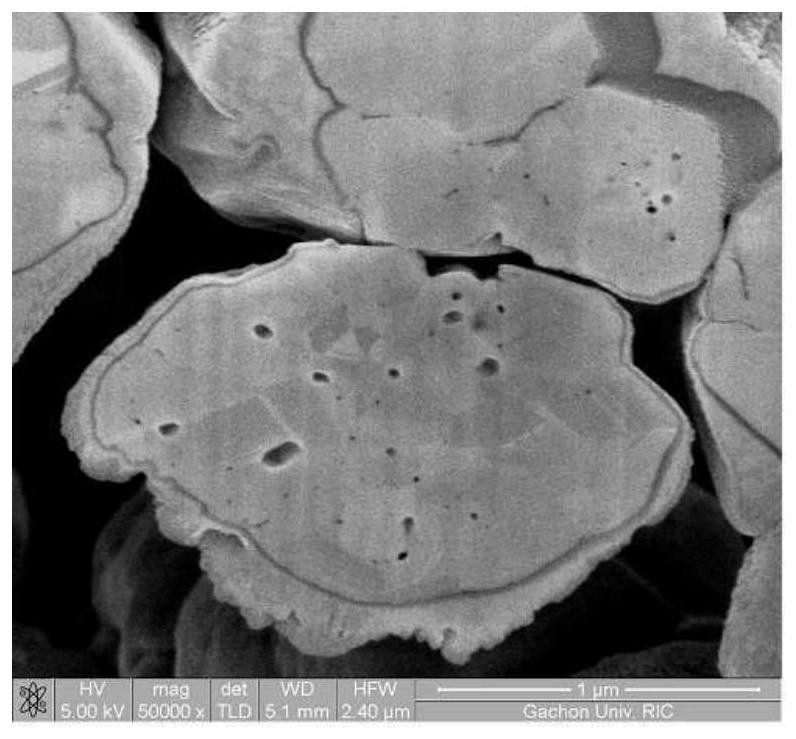

Image

Examples

Embodiment 1

[0063] Pour 40kg of distilled water into the reactor, mix 800g of 10% HEC (hydroxyethyl-cellulose: hydroxyethyl-cellulose, Sigma-Aldrich, CAS No.9004-62-0), and then add 24Kg of 28% ammonia solution and stir. At this time, the temperature of the solution in the reactor was maintained at 50°C. A container is prepared as follows: 25.8Kg of silver nitrate and 12Kg of 28% ammonia solution are stirred. 10Kg of 50% caustic soda aqueous solution is prepared in the B container. Then, the following preparations were made in container C: 5Kg of a 37% aqueous formaldehyde solution (formalin) was added to 21Kg of distilled water, and 4Kg of a 10% arabic gum solution was added, followed by stirring.

[0064] While stirring the solution in the reactor at a speed of 2,000 rpm, the prepared solutions in the containers A, B, and C were simultaneously charged into the reactor at a speed of 0.5 kg per minute to produce slurry. The obtained slurry was washed and filtered with distilled water, ...

Embodiment 2

[0066]Pour 40kg of distilled water into the reactor, mix 800g of 10% HEC (hydroxyethyl-cellulose: hydroxyethyl-cellulose, Sigma-Aldrich, CAS No.9004-62-0), and then add 24Kg of 28% ammonia solution and stir. At this time, the temperature of the solution in the reactor was maintained at 85°C. A container is prepared as follows: 25.8Kg of silver nitrate and 12Kg of 28% ammonia solution are stirred. 8Kg of 50% caustic soda aqueous solution is prepared in container B. Then, the following preparations were made in container C: 5Kg of 37% formaldehyde aqueous solution was added to 21Kg of distilled water, and 4Kg of 10% arabic gum solution was added, followed by stirring.

[0067] While stirring the solution in the reactor at a speed of 2,000 rpm, the prepared solutions in the containers A, B, and C were simultaneously charged into the reactor at a speed of 1.0 kg per minute, thereby producing a slurry. The obtained slurry was washed and filtered with distilled water, then dried ...

Embodiment 3

[0069] Pour 40kg of distilled water into the reactor, mix 800g of 10% HEC (hydroxyethyl-cellulose: hydroxyethyl-cellulose, Sigma-Aldrich, CAS No.9004-62-0), and then add 24Kg of 28% ammonia solution and stir. At this time, the temperature of the solution in the reactor was maintained at 20°C. A container is prepared as follows: 25.8Kg of silver nitrate and 12Kg of 28% ammonia solution are stirred. 10Kg of 50% caustic soda aqueous solution is prepared in the B container. Then, the following preparations were made in container C: 5Kg of 37% formaldehyde aqueous solution was added to 21Kg of distilled water, and 4Kg of 10% arabic gum solution was added, followed by stirring.

[0070] While stirring the solution in the reactor at a speed of 2,000 rpm, the prepared solutions in the containers A, B, and C were simultaneously charged into the reactor at a speed of 3.0 kg per minute, thereby producing a slurry. The obtained slurry was washed and filtered with distilled water, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com