Composite catalyst for synthesizing benzene through methane anaerobic aromatization and preparation method and application thereof

A technology of catalyst and chemical synthesis, which is applied in the field of composite catalyst and its preparation, can solve the problems of low conversion rate of methane and other problems that are not involved in the report of composite catalyst, and achieve the improvement of conversion rate and benzene yield, conversion rate and product benzene The effect of increasing the yield and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

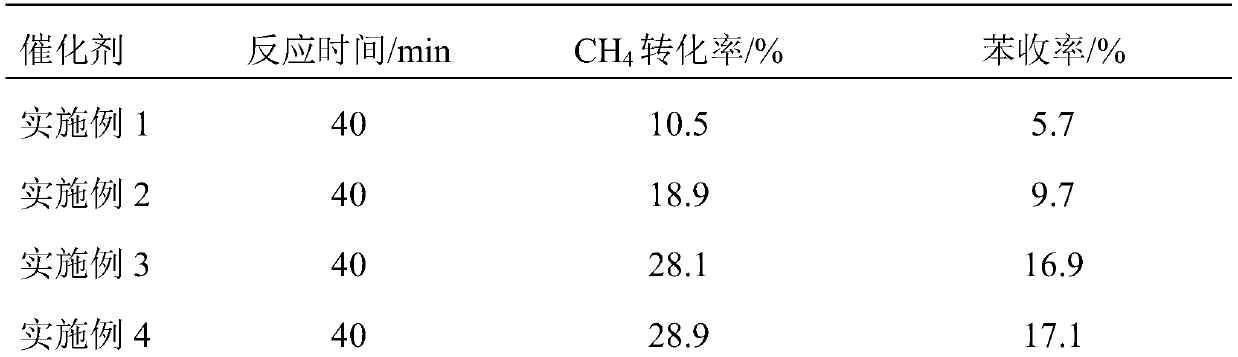

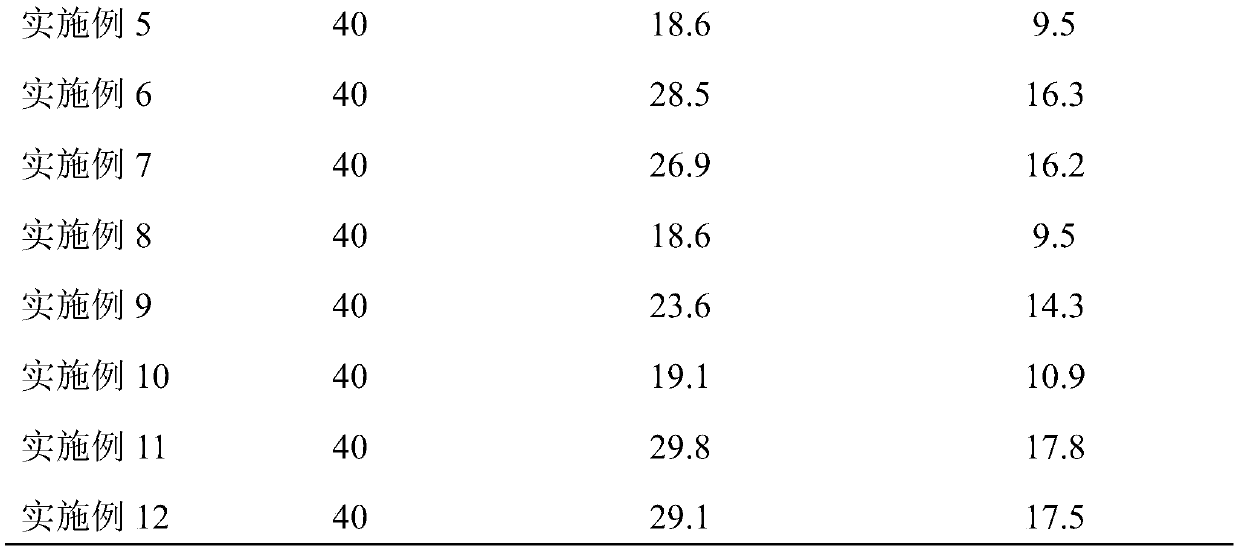

Examples

Embodiment 1

[0040] 1.1 Preparation method

[0041] 2%Mo1.5%Fe0.05%Mg / ZSM-5 catalyst was prepared by co-impregnation method. First, the ZSM-5 molecular sieve was calcined at 400°C for 24 hours; secondly, the calcined ZSM-5 molecular sieve was impregnated into (NH 4 ) 6 Mo 7 o 24 , Fe(NO 3 ) 3 and Mg(NO 3 ) 2 in the aqueous solution (the mass ratio of the three is 11.4:

[0042] 21.3: 1) Stir for 8 hours, evaporate to dryness at 110°C, and dry at 90°C for 16 hours; finally, put it in a muffle furnace and roast at 400°C for 8 hours, and the prepared catalyst powder is tabletted, crushed and screened to obtain 40-60 Objective Mo-based solid-phase catalyst.

[0043] The above-mentioned Mo-based solid-phase catalyst was loaded into a fixed-bed reactor, and the catalyst was pre-carbonized with methane for 20 min at 700 °C and a space velocity of 5 L / g h.

[0044] The above-mentioned pre-carbonized Mo-based solid-phase catalyst was unloaded, and then physically mixed with 40-60 mesh met...

Embodiment 2

[0048] 2.1 Preparation method

[0049] 6%Mo0.7%Co0.2%Mn / ZSM-11 catalyst was prepared by co-impregnation method. First, the ZSM-11 molecular sieve was calcined at 500 °C for 12 h; secondly, the calcined ZSM-11 molecular sieve was impregnated into (NH 4 ) 6 Mo 7 o 24 , Co(NO 3 ) 2 and Mn(NO 3 ) 2 (the mass ratio of the three is 16.0:3.3:1) and stirred for 18h, evaporated to dryness at 110°C, and dried at 110°C for 12h; finally, put it into a muffle furnace and roast at 500°C for 5h, and the prepared catalyst powder was After tableting, crushing and screening, a Mo-based solid-phase catalyst of 40-60 meshes is obtained.

[0050] The above-mentioned Mo-based solid-phase catalyst was loaded into a fixed-bed reactor, and the catalyst was pre-carbonized with methane for 30 min at 650 °C and a space velocity of 2 L / g h.

[0051] The above pre-carbonized Mo-based solid-phase catalyst was physically mixed with 40-60 mesh metal Ti particles at a mass ratio of 1:1.5 to obtain an ...

Embodiment 4

[0061] 4.1 Preparation method

[0062] 10%Mo0.1%Ru0.5%Rh / MCM-49 catalyst was prepared by co-impregnation method. First, the MCM-49 molecular sieve was calcined at 500°C for 18 hours; secondly, the calcined MCM-49 molecular sieve was impregnated into (NH 4 ) 6 Mo 7 o 24 , Ru(NO)(NO 3 ) 3 and Rh(NO 3 ) 3 The aqueous solution (the mass ratio of the three is 55.3:1:4.5) was stirred for 12h, evaporated to dryness at 110°C, and dried at 120°C for 8h; finally, it was put into a muffle furnace and calcined at 500°C for 1h, and the prepared catalyst powder was After tableting, crushing and screening, a Mo-based solid-phase catalyst of 40-60 meshes is obtained.

[0063] The above-mentioned Mo-based solid-phase catalyst was loaded into a fixed-bed reactor, and the catalyst was pre-carbonized with methane for 10 min at 750 °C and a space velocity of 5 L / g h.

[0064] The above pre-carbonized Mo-based solid-phase catalyst and 40-60 mesh 50%Zr50%Ti particles were physically mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com