Hollow glass drying agent and method for producing the same

A desiccant, glass technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of potential safety hazards, high powder drop rate, poor adsorption selectivity, etc., and achieve novel preparation technology and composition. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

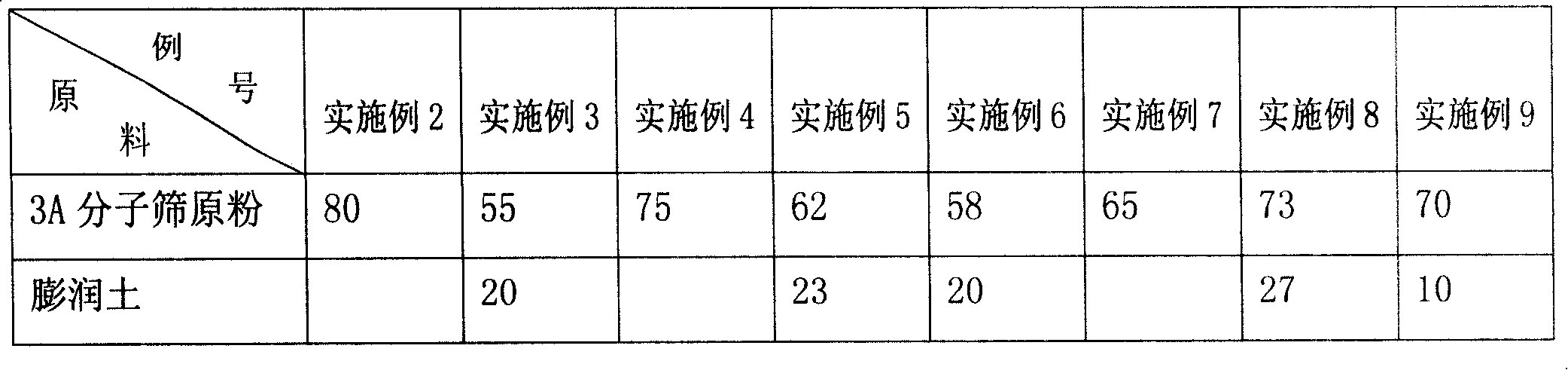

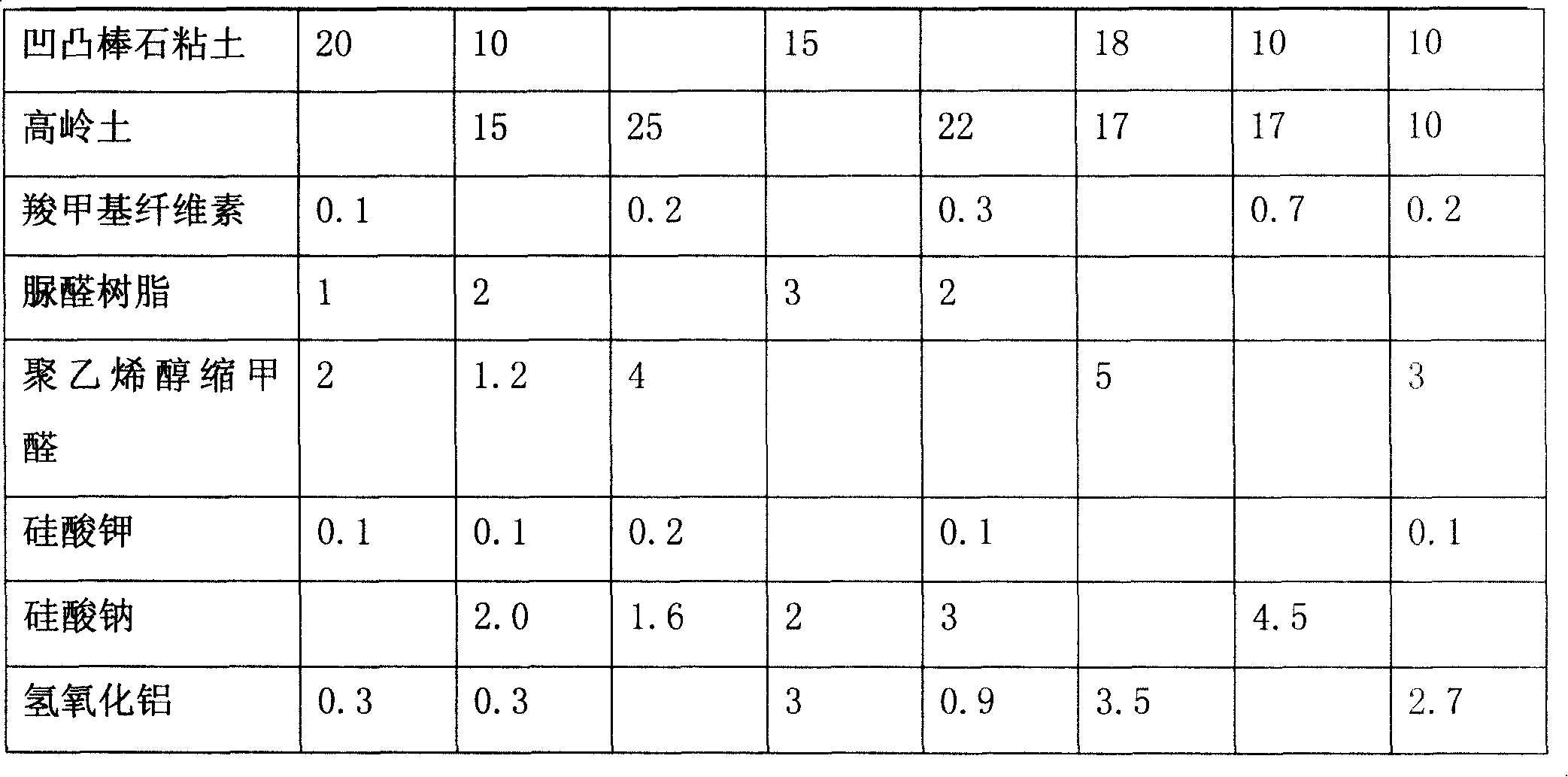

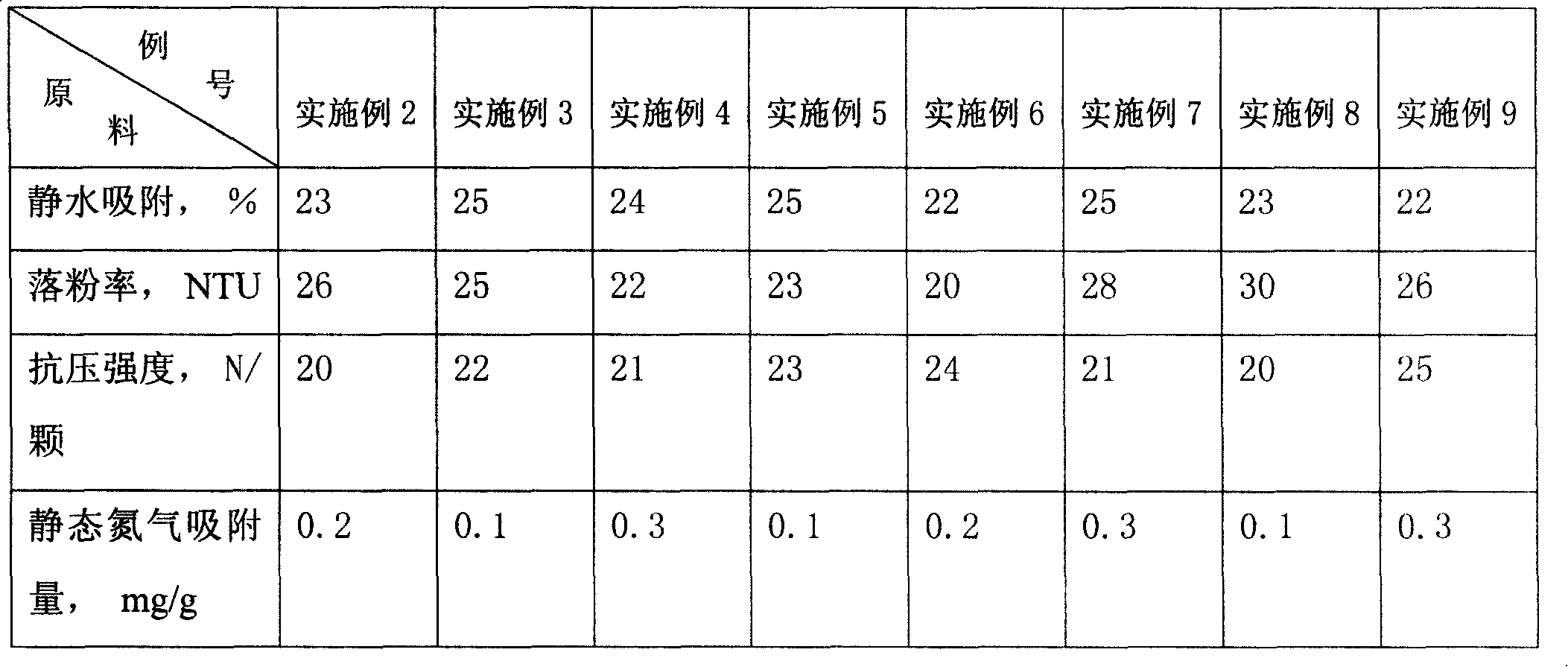

[0030] Mix 50 kg of measured 3A molecular sieve raw powder with 20 kg of kaolin, 15 kg of attapulgite clay and 15 kg of bentonite, and transport them to the rotary automatic ball forming machine. Add 0.5 kg of water-soluble adhesive carboxymethyl cellulose Soluble in water and diluted with an appropriate amount of water, while continuously spraying the aqueous adhesive solution, the small balls gradually grow up and form a molecular sieve body with a certain particle size. Then, dissolve 0.1 kg of potassium silicate, an additional compressive strength enhancer, in 10 kg of water, and spray the prepared aqueous solution of potassium silicate onto the formed molecular sieve body to coat and reinforce it; then transfer it to a special granular Dry it in a natural energy drying car for 20-40 hours, then blow off the dust with compressed air in a powder blower and polish it; bake it in a roasting furnace at a temperature of 480-700°C for 2-6 hours. After passing the inspection, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com