Testing device of crankshaft rotor-bearing system dynamics experimental bench

A test device and test bench technology, applied in mechanical bearing testing, engine testing, measuring devices, etc., can solve the problems of backward manufacturing capacity of marine crankshafts, restricting the development of the shipbuilding industry, etc., and achieve the effect of perfect understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

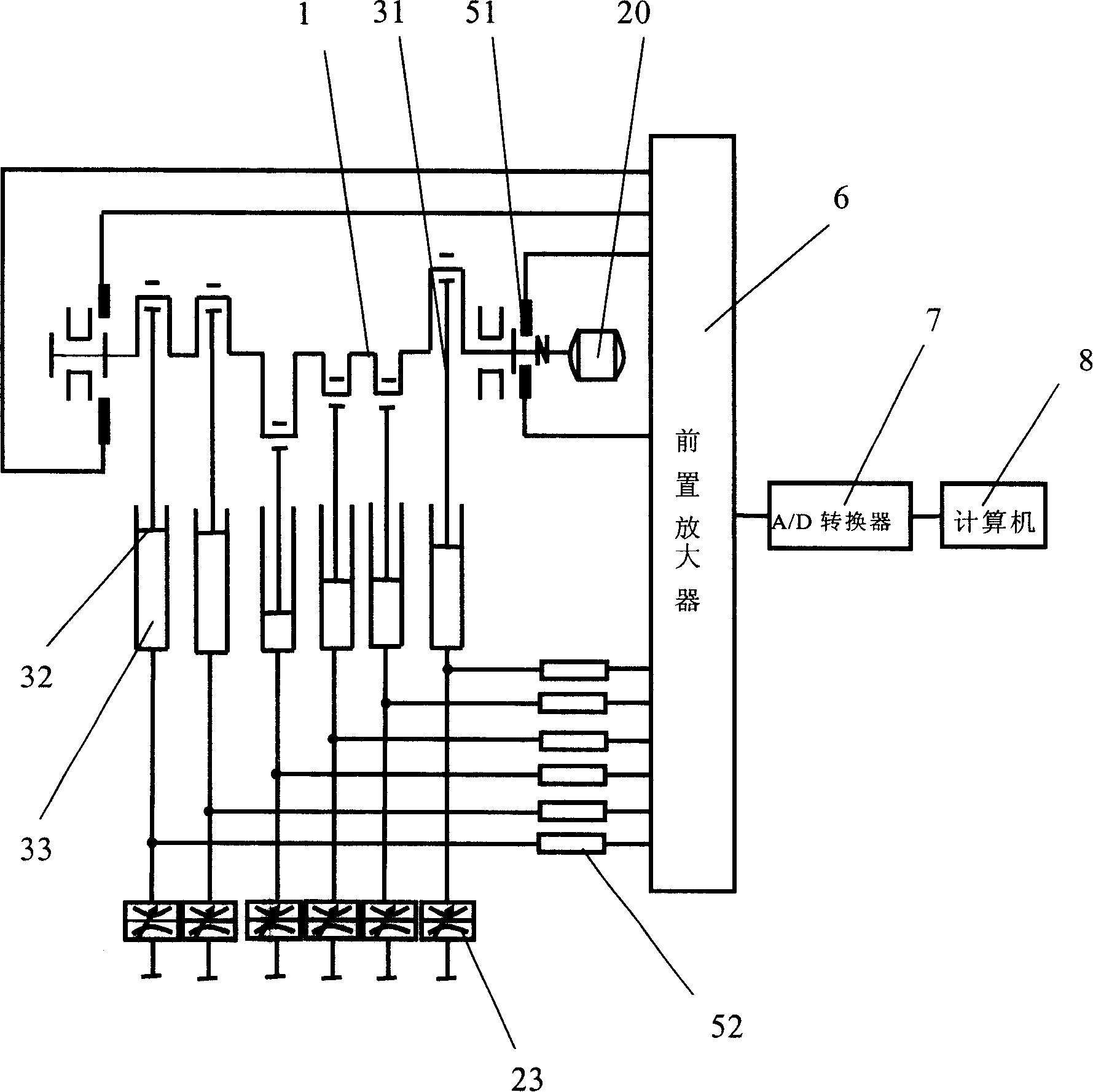

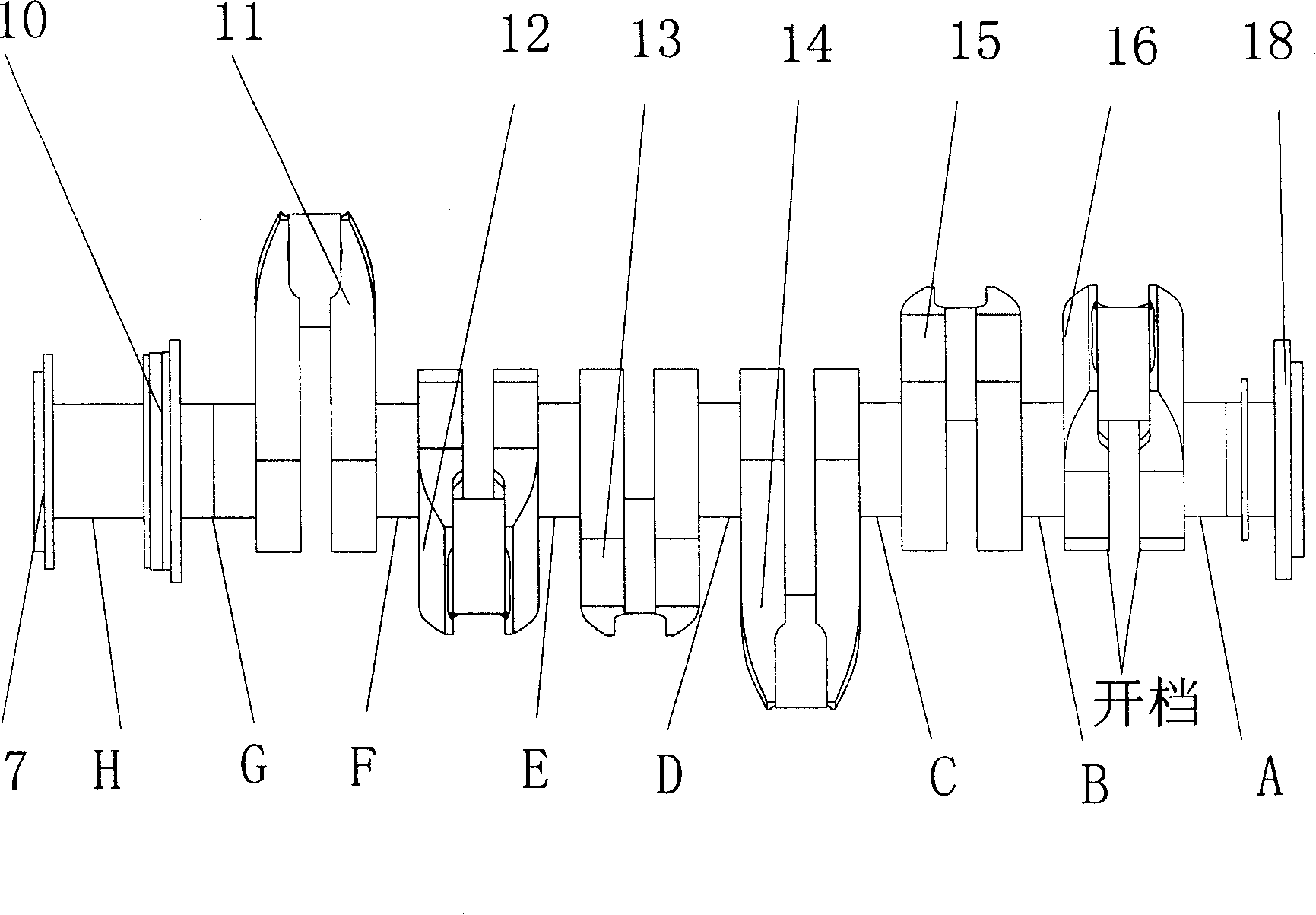

[0014] see figure 1 and figure 2 , the testing device of the test bench for simulating the crankshaft rotor-bearing system dynamics of the present invention includes a driving device, a supporting device, a measured crankshaft 1, a loading device, and a signal measuring device. The crankshaft 1 to be tested has thrust discs 17, 18 at the front and rear ends, six bell cranks 11-16 and a sprocket 10 are arranged in the middle, and are connected to the thrust discs 17, 18 and six bell cranks 11-16 and Between the sprocket wheels 10 are journals A~H, which are supported by a support device and fixed on the test bench. The support device includes a sliding bearing (not shown), and the sliding bearing is fixed on the test bench and supported on the test bench Measure the journals A to H of the crankshaft. The drive device drives the measured crankshaft 1 to rotate. The drive device includes a motor, a reducer and a coupling 21. The motor and the reducer are integrated, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com