Multi-optical fiber melt-pulling method

A multi-fiber, multi-fiber technology, applied in the coupling of optical waveguides, etc., can solve the problems of fewer taps, small bandwidth, and large signal attenuation, and achieve the effects of less power loss, round shape, and small attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

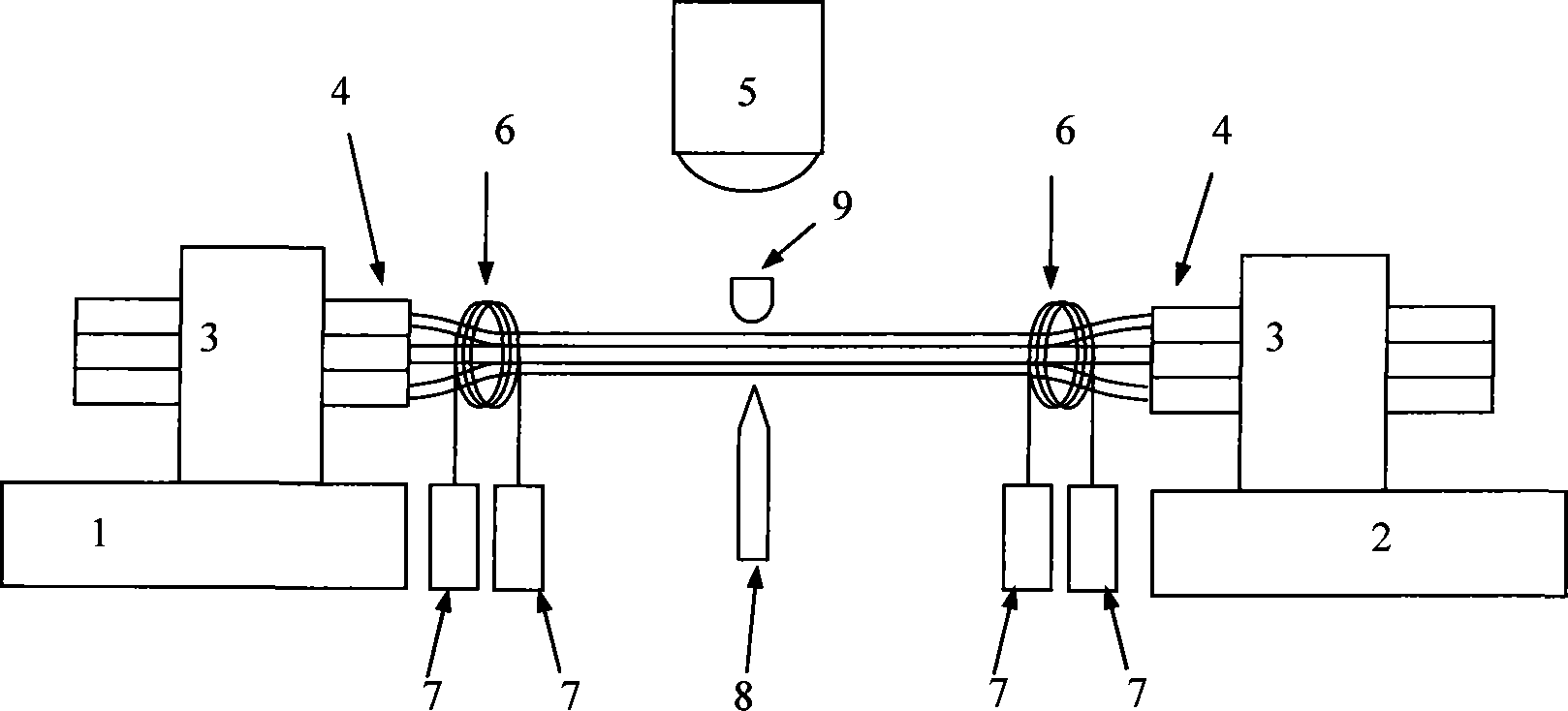

[0015] Referring to the accompanying drawings, the steps of the fiber melting process are as follows:

[0016] A. Adsorb the fiber bundle 4 on the two suction seats 3, and peel off the cladding of the middle section of each optical fiber at an appropriate length to expose the bare fiber. The two suction seats 3 are used to fix the fiber bundle 4 to make it close and straighten ;

[0017] B. Tie two heavy hammers 7 at the two ends of the fiber filament 6, bind them on the bare optical fibers at the left and right ends respectively, and gather the multiple optical fibers of the optical fiber bundle by the gravity of the heavy hammers;

[0018] C. The burner 5 is installed on a platform that can move up and down, front and back, left and right, and moves to the melting and drawing position of the bare optical fiber under the control of the computer. The burning head 5 forms a torch through combustible gas combustion, and forms a high temperature at the melting and drawing positio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap