Silicon based LCD unit and method for forming the same

A silicon-based liquid crystal and display technology, applied in the direction of instruments, electrical components, electric solid devices, etc., can solve problems such as leakage, affect the performance of switching circuits, reduce display refresh frequency, etc., and achieve the effect of reducing refresh frequency and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by describing specific embodiment in detail according to accompanying drawing, above-mentioned object and advantage of the present invention will be clearer:

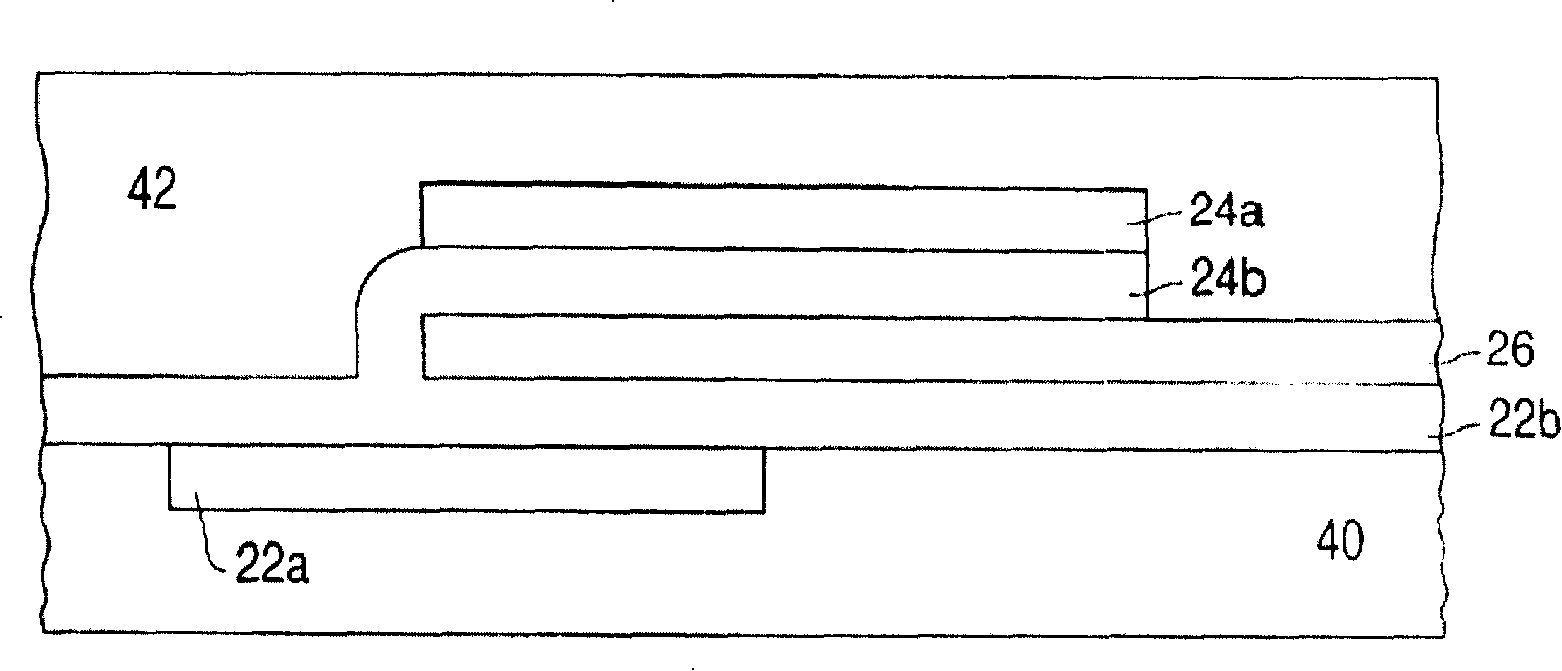

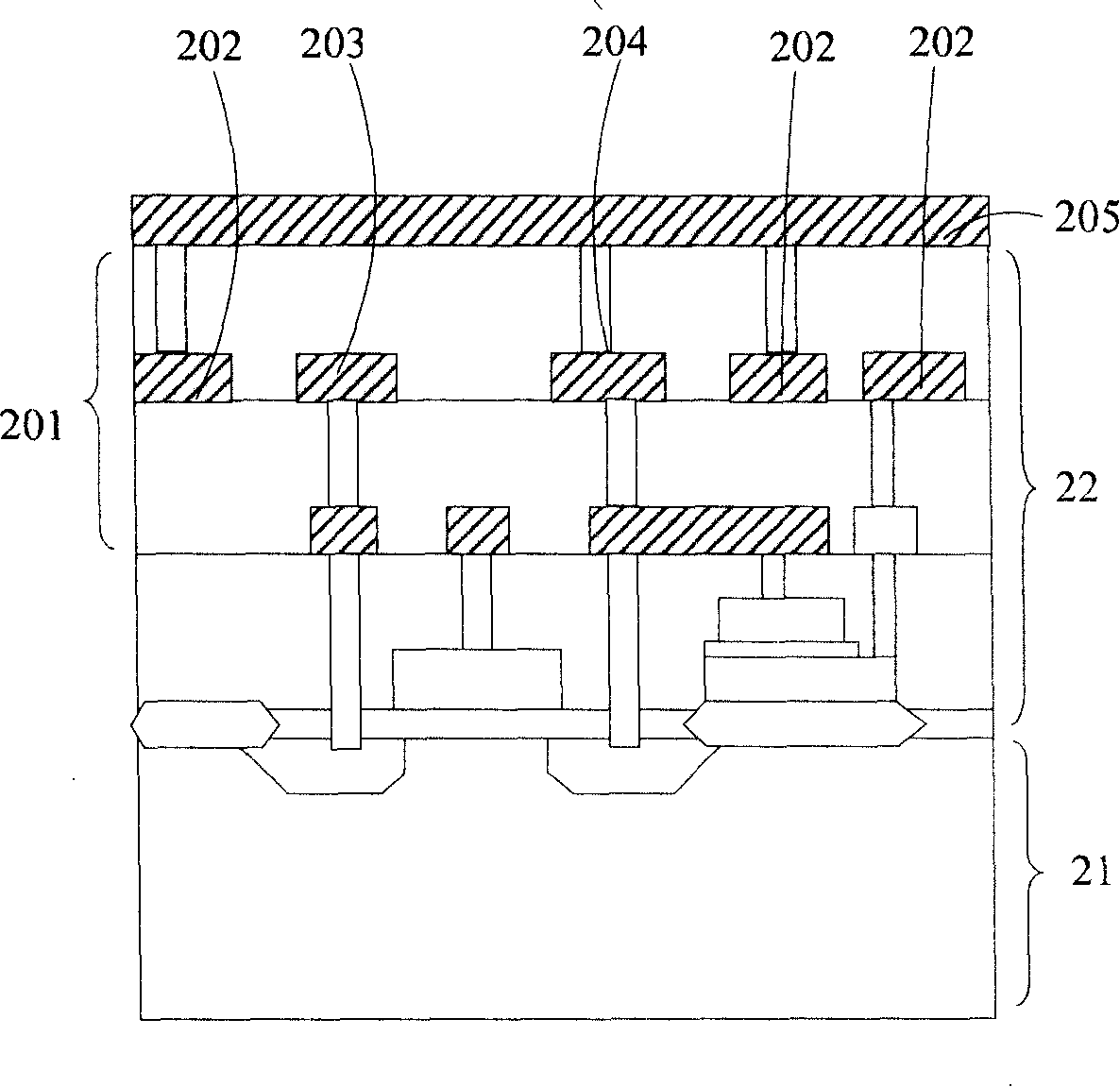

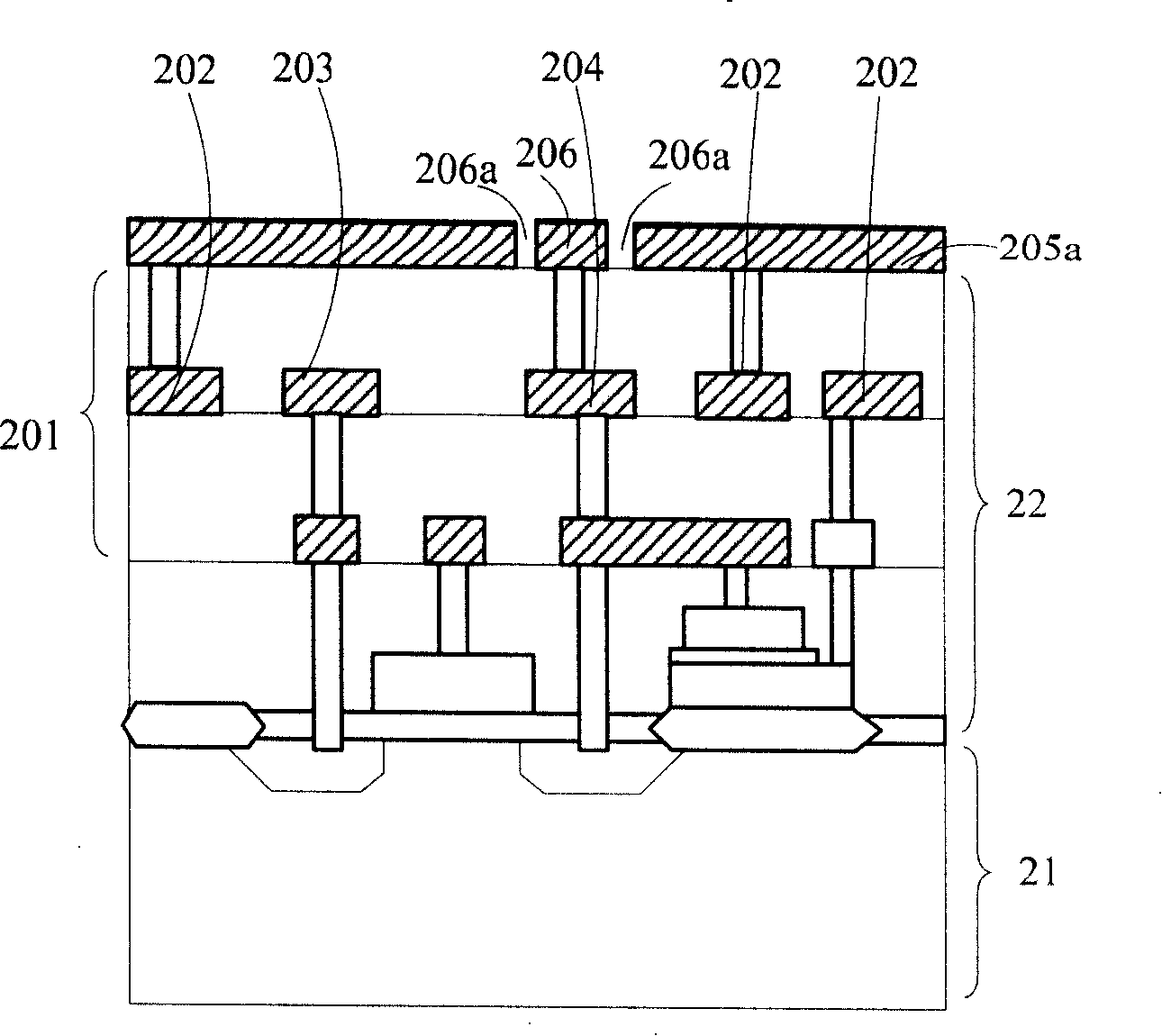

[0027] First, a method for forming a liquid crystal on silicon display unit is given, including forming a pixel switch circuit layer on a silicon substrate, the pixel switch circuit layer including a metal-oxide-semiconductor field effect transistor and a metal-oxide-semiconductor The source terminal of the field effect tube is connected in series with the first capacitor; a light shielding layer is formed on the pixel switch circuit layer; an insulating layer is formed on the light shielding layer; a micro-mirror layer is formed on the insulating layer, and the micro-mirror layer, the insulation The layer and the light-shielding layer form a capacitor, the micro-mirror layer is electrically connected to the source end of the metal-oxide-semiconductor field effect transistor, and the light-shielding layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com