Stamping formed metal connection board and girders

A metal connecting plate, stamping and forming technology, applied in the direction of truss structure, truss beam, joist, etc., can solve the problems of difficult connection, bearing capacity and stiffness, etc., to overcome the large production workload, good versatility and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

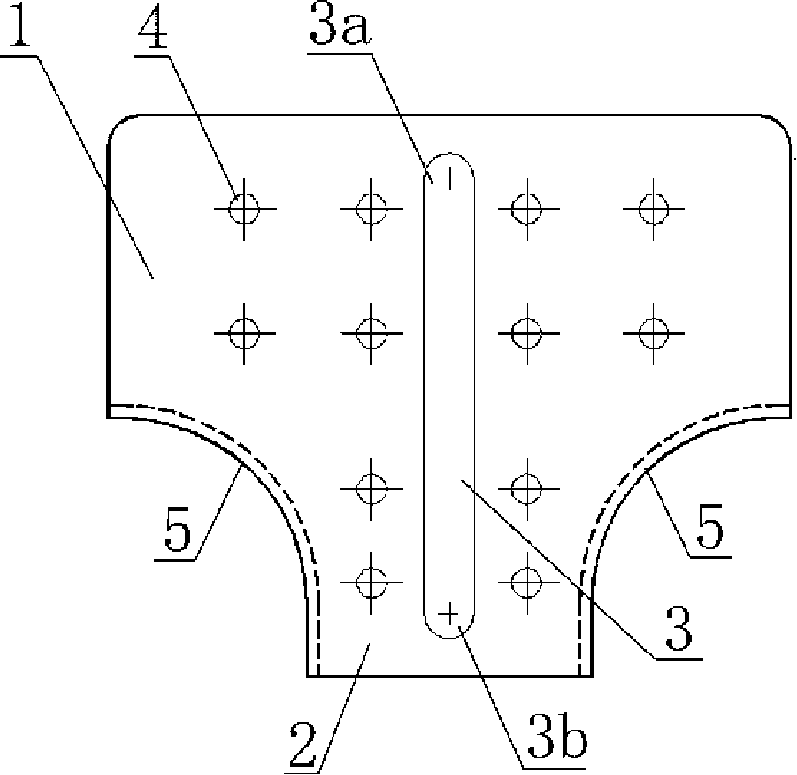

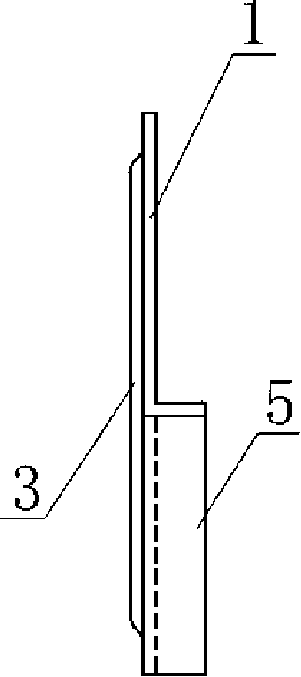

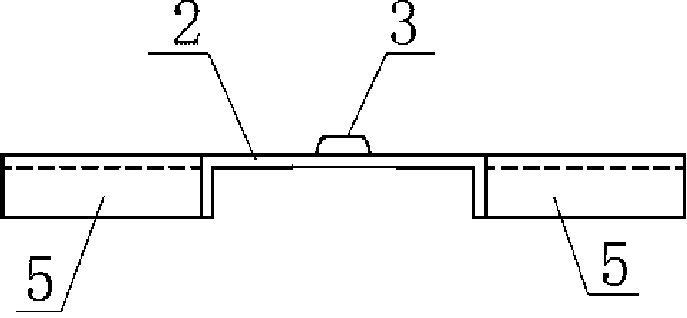

[0044] Example one see figure 1 -4. This kind of stamped and formed metal connecting plate is used for a metal truss composed of a chord 7 and a vertical web 8 connected.

Embodiment 2

[0045] See the second embodiment Figure 5 -8. This kind of stamped and formed metal connecting plate is used for a metal truss formed by a chord 7 and two diagonal webs 10 connected together.

Embodiment 3

[0046] See the third embodiment Figure 9-1 2. This kind of stamped and formed metal connecting plate is used for a metal truss composed of a chord 7, a vertical web 8 and two oblique webs 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com