Numerical control hydraulic system of switch reluctance motor pump

A switched reluctance motor, hydraulic system technology, applied in mechanical equipment, fluid pressure actuation devices, servo motors, etc., can solve the complex speed regulation and torque control, low efficiency of electro-hydraulic servo system, starting and overload torque Small and other problems, to achieve the effect of flexible motor control, good development and application prospects, and elimination of throttling losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] refer to figure 1 :

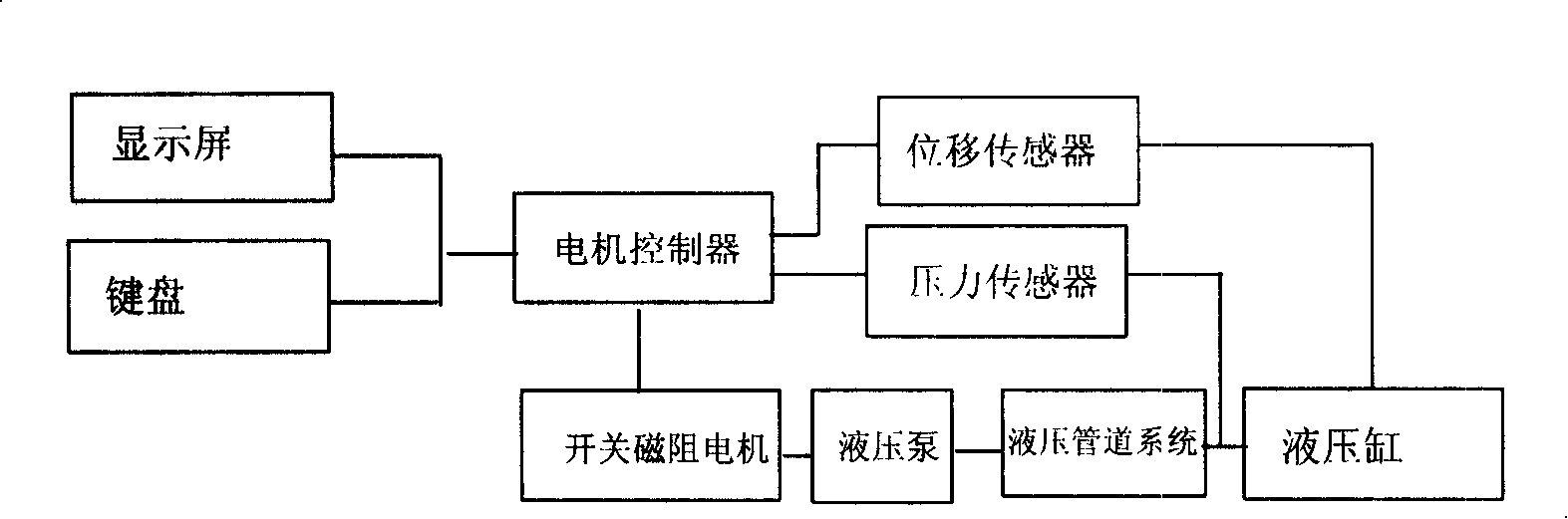

[0021] The motor controller is connected to the switched reluctance motor, the switched reluctance motor is connected to the hydraulic pump, the hydraulic pump is connected to the hydraulic cylinder through the hydraulic pipeline system, the pressure sensor is set on the pipeline, and the displacement sensor is set on the fuselage, the output signals of the pressure sensor and the displacement sensor The motor controller is connected, and the external port of the motor controller 1 is provided with a keyboard 14 and a display 13 .

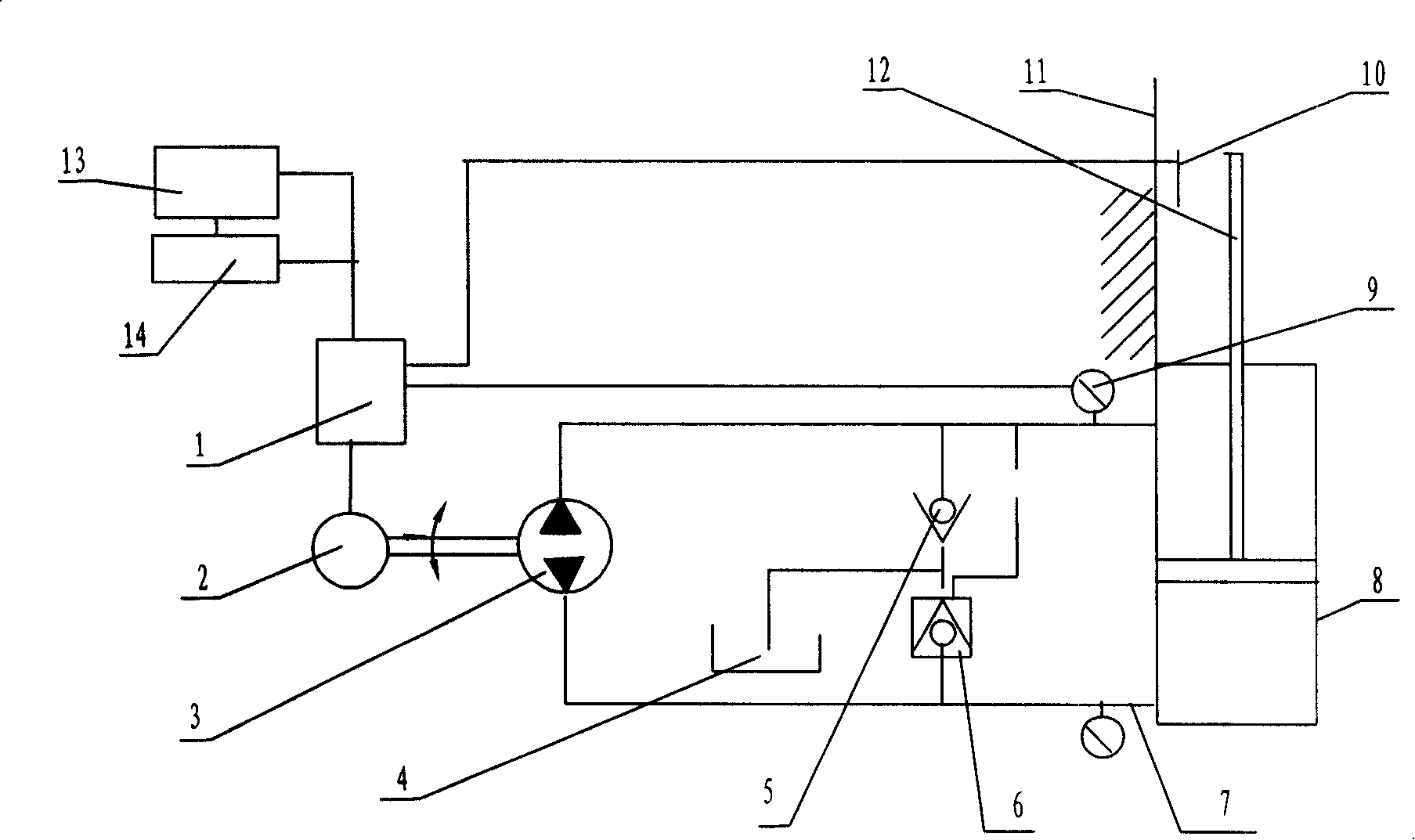

[0022] refer to figure 2 :

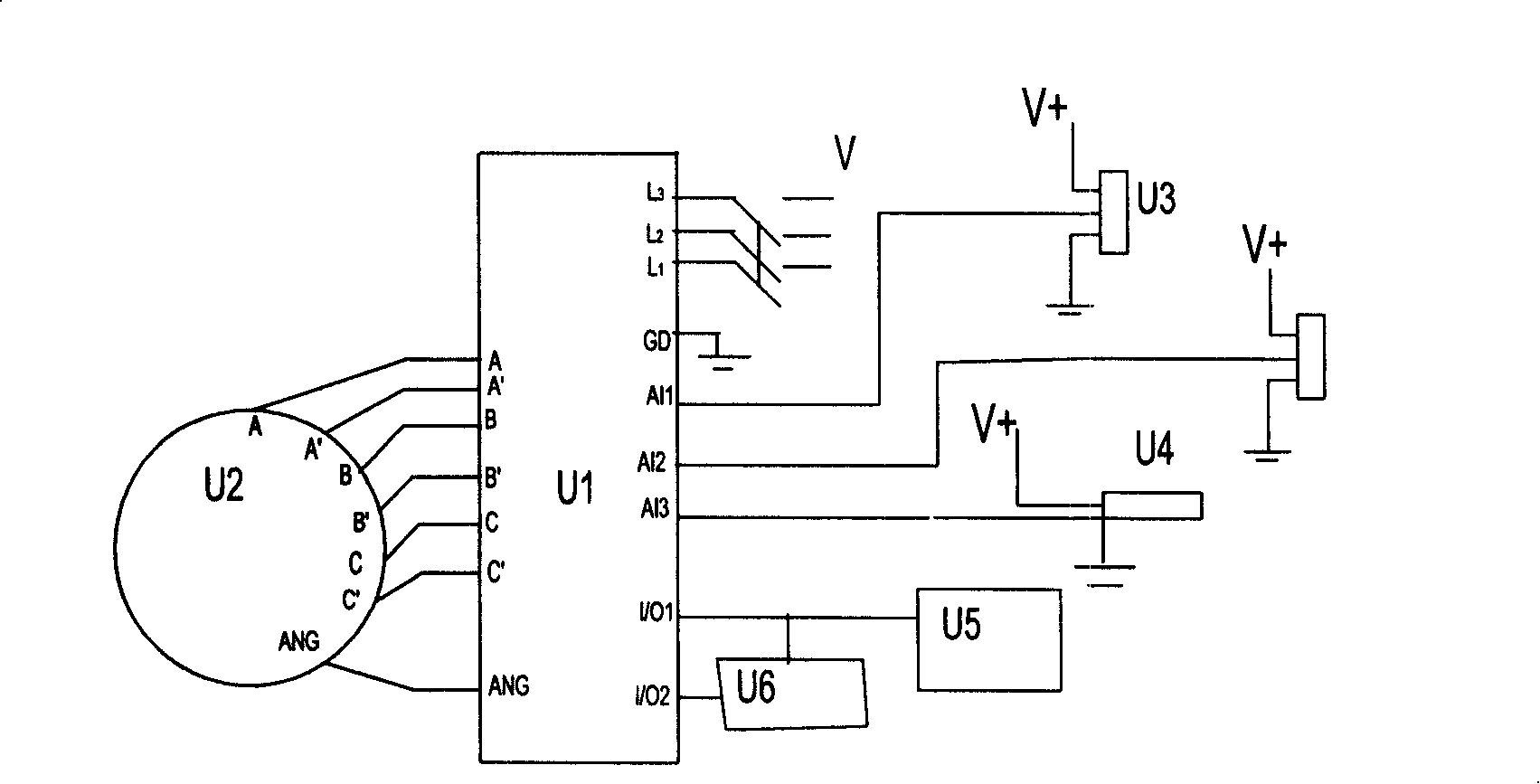

[0023] The ports A, A', B, B', C, C' and ANG of the switched reluctance motor U2 are respectively connected to the ports A, A', B, B', C, C' and ANG of the motor controller U1. The L1, L2, L3 ports of the controller U1 are connected to the power supply, two pressure sensors U3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com