Apparatus and method for monitoring resistance spot welding quality

A technology of resistance spot welding and quality monitoring, applied in the direction of measuring devices, resistance welding equipment, welding equipment, etc., can solve the problems of signal distortion, lack of better practical methods, and failure to obtain universal characteristic information of resistance spot welding quality. To achieve the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

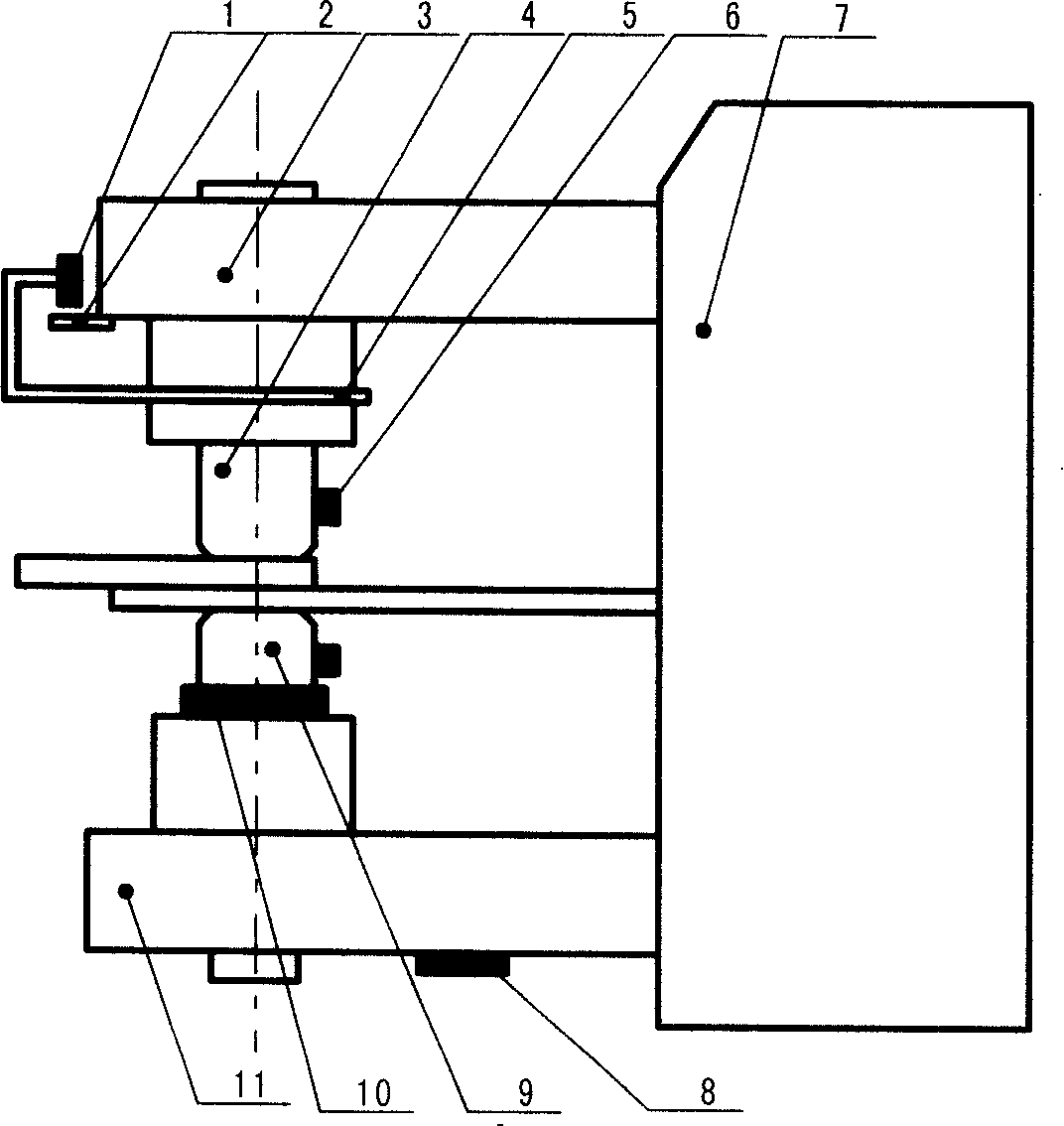

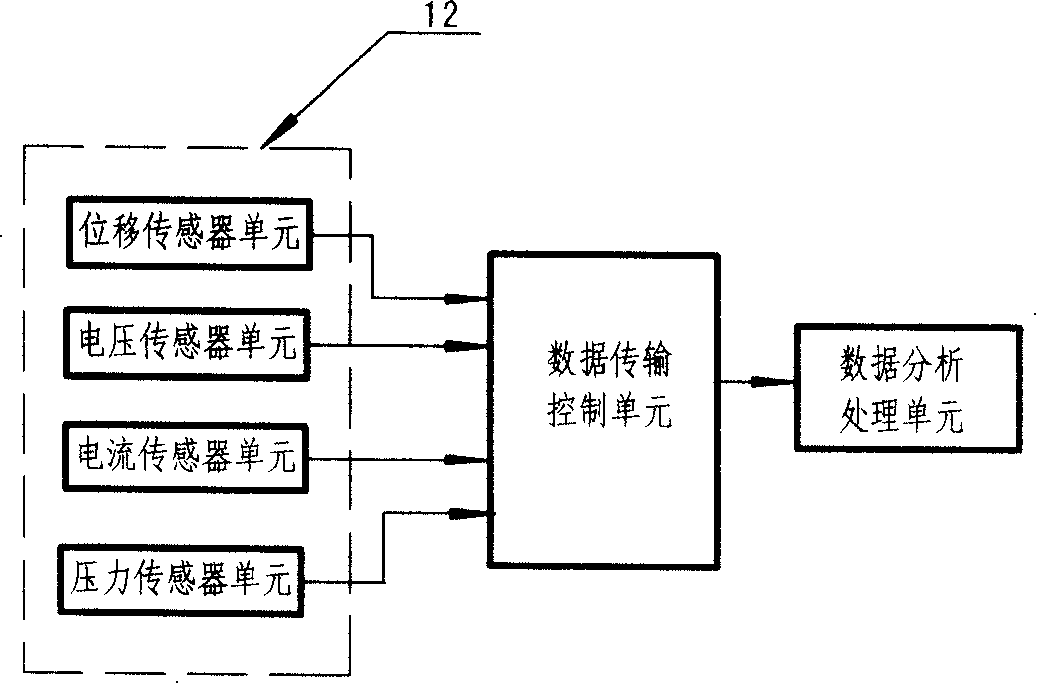

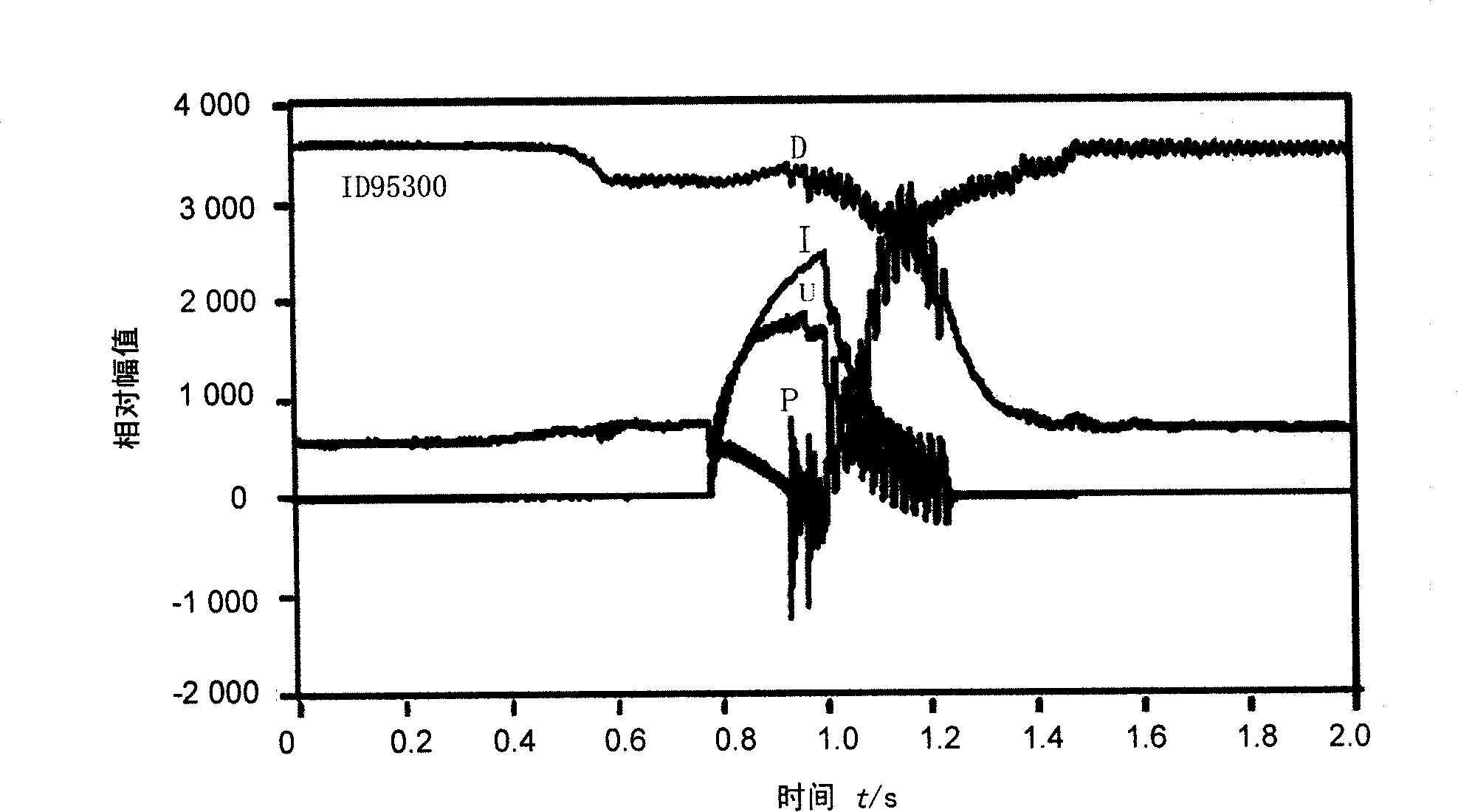

[0038] The following takes the DJ-1000 DC spot welding machine as the main body of the resistance welding equipment as an example. The resistance spot welding quality monitoring device consists of the main body 7 of the resistance spot welding equipment, the upper arm 3, the lower arm 11, the upper electrode The electrode 9 is composed of a displacement sensor 1 installed above the rigid bracket 5 fixed on the upper electrode. The lower surface of the displacement sensor is parallel to the metal plate 2 extending horizontally from the outside of the upper machine arm. The displacement sensor realizes synchronous movement with the upper electrode. The change of the relative position with the metal plate reflects the change of the distance between the two; the two electrodes of the voltage sensor 6 are respectively installed on the upper electrode and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com