High performance radial hot pressing magnet ring and preparation method thereof

A high-performance, magnetic ring technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of increasing oxygen content and reducing the performance of anisotropic magnets, achieving low oxygen content, inhibiting cracking, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

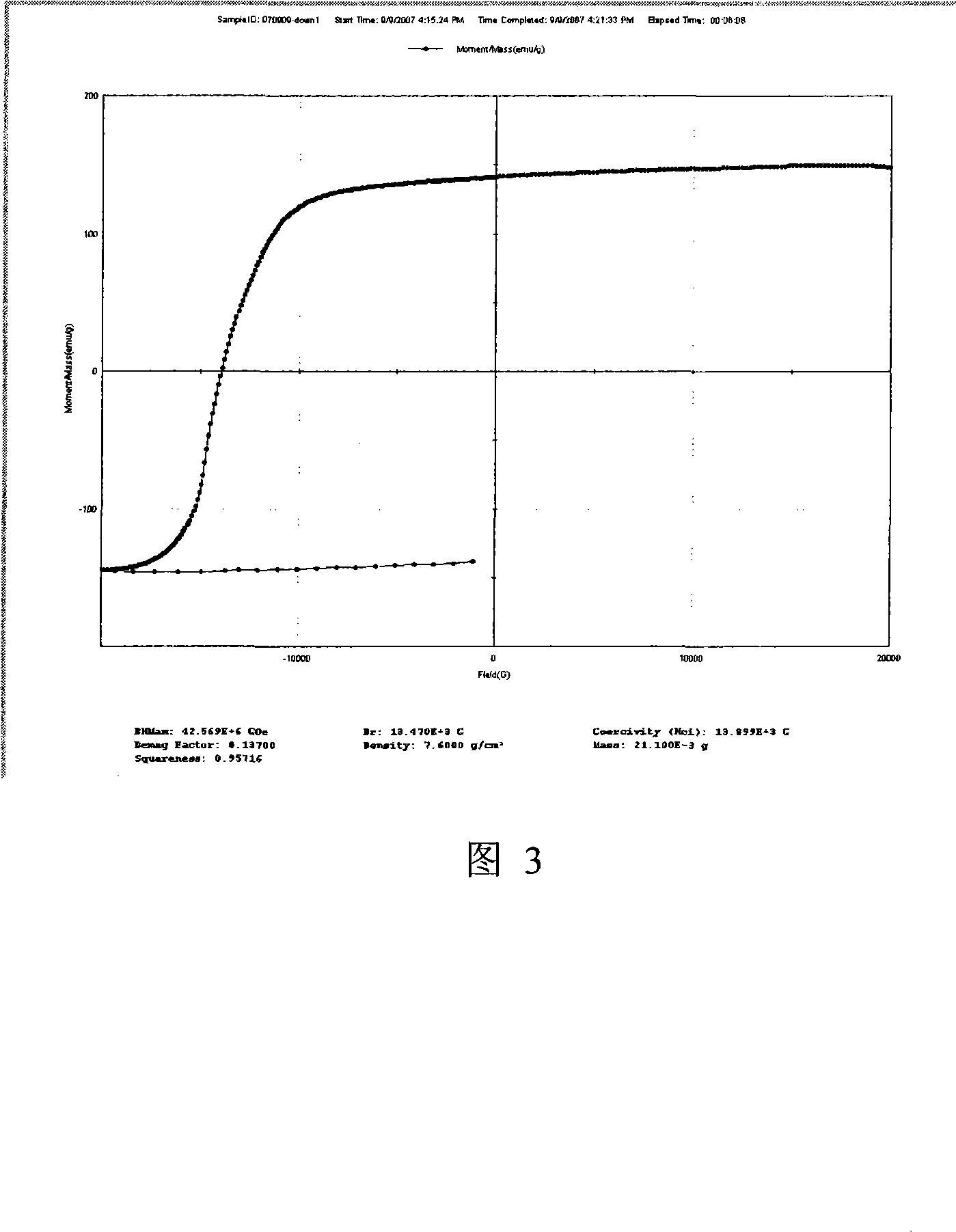

[0053] Table 1 is the specific chemical composition of the high-performance hot-pressed ring of the present invention; Table 2 is the preparation process of the high-performance hot-pressed ring of the present invention; Table 3 is the magnetic properties and oxygen content of the hot-pressed ring of the embodiment of the present invention measured by VSM And the performance comparison of the existing technology.

[0054] Table 1: Chemical composition (at%) of the high-performance hot-pressed ring of the embodiment of the present invention

[0055]

[0056] Table 2: Hot pressing / thermal deformation process of the high-performance hot pressing ring according to the embodiment of the present invention

[0057]

[0058] Table 3: Magnetic properties of the high-performance hot-pressed ring of the embodiment of the present invention

[0059]

[0060] Note: In the embodiment, 1(1)+2(2) refers to the combination of the component (1) in Table 1 and the process (2) in Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic energy product | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com