Method of biological treatment for organic sewage and apparatus therefor

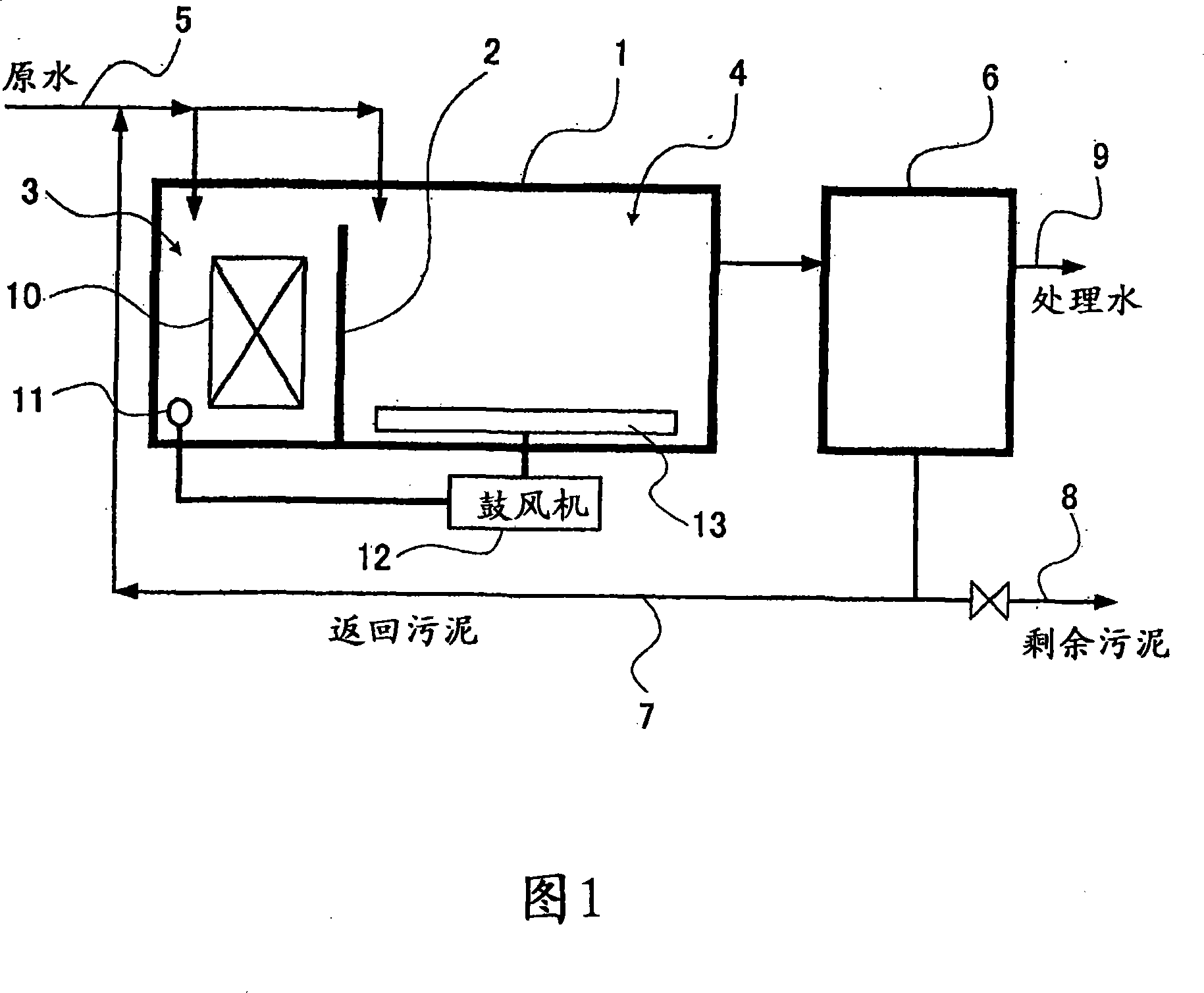

A technology for biological treatment and sewage, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Mud settlement and concentration, sand sedimentation and accumulation at the bottom of the aeration tank, etc., to achieve the effect of easy increase of BOD concentration, easy increase, and easy sewage water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] [Discussion on the appropriate ratio of (volume of microbial adhesion material) / (total volume of aeration tank)]

[0049] An appropriate ratio of (volume of microorganism-attached material) / (total volume of aeration tank), that is, a ratio necessary for obtaining the effect of improving the settleability of activated sludge, was investigated using a laboratory-scale apparatus. The details are described below.

[0050] The shaking bed "Biofringe" manufactured by NET Co., Ltd. is set to a length of 40 cm, and many "Biofringe" are closely installed in the formwork of various volumes shown in Table 1 in a manner that there is basically no interval between each other, thereby preparing Good volume of various microbial attachment materials. In addition, a plurality of aeration tanks (20 cm in length, 50 cm in width, and 50 cm in water depth) with an effective volume of 50 liters were fabricated, and various microorganism-adhering materials of different volumes were immersed ...

Embodiment 2

[0057] [Discussion on appropriate conditions for BOD volume loading of microorganism-attached materials]

[0058] Appropriate conditions for the BOD volumetric loading of microorganism-attached materials were investigated using a laboratory-scale device.

[0059] The aeration tank (volume 50 liters) and sedimentation tank used in the test of Example 1 were used. The aeration tank was filled with a "Biofringe" type microorganism attachment material having the same constitution as in Example 1 but having a volume of 20 liters. For comparison, the test was also carried out without filling with the microorganism attachment material. Then, by changing the amount of raw water treatment, various changes are made to the BOD volume load of the microorganism-attached material. Raw water adopts the BOD used in embodiment 1 as the corn steep liquor dilution water of 1000mg / L.

[0060] Table 2 shows the test results. As shown in Table 2, the BOD volume load of the microbial attachment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com