Method for producing skin-core structural micro-wave screening functional fibre by melt direct spinning

A technology of functional fiber and skin-core structure, which is applied in fiber processing, textiles and papermaking, and single-component polyester rayon. It can solve the problems of uneven physical and chemical properties of products, difficult process control, and long production process. To achieve the effect of facilitating industrial promotion and application, solving the problem of poor fine-tuning of the process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

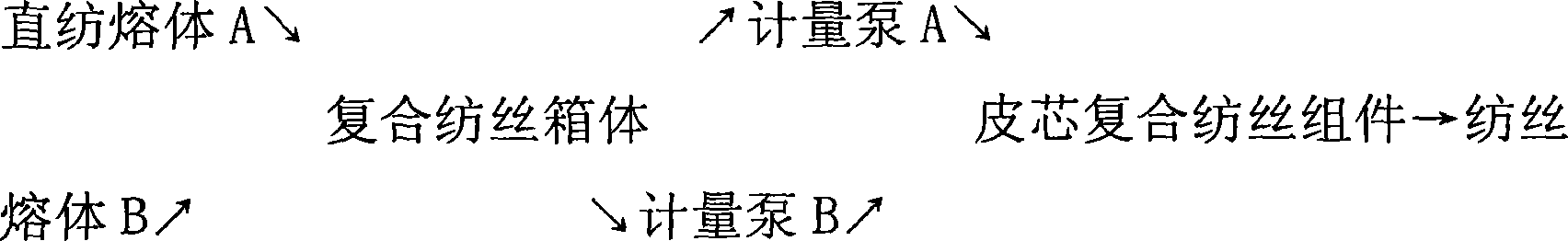

Method used

Image

Examples

Embodiment Construction

[0017] Provide 1 concrete implementation example of the present invention below:

[0018] Take 76 parts of PET slices with a melt index of 50, 5 parts of copper powder with an average particle size of 40nm, 4 parts of γ-methylacrylphthaleinoxytrimethoxysilane, and 6 parts of barium ferrite magnetic powder with an average particle size of 38nm , 9 parts of isopropyl tris(dodecylbenzenesulfonate)ferrate with an average particle size of 1 μm, after being fully mixed, the fiber skin melt was produced by twin-screw extrusion at 190°C; The sheath-core volume ratio is 2:8, and the microwave-shielding PET filament with sheath-core composite structure is produced by melt direct spinning.

[0019] It is determined that the microwave reflection attenuation rate of the obtained fiber is 10db, and the x-ray shielding rate can reach 79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com