Drive unit of gas discharge lamp

A technology for gas discharge lamps and driving devices, which is applied in the use of gas discharge lamps, output power conversion devices, lighting devices, etc., and can solve problems such as high starting frequency, increased power consumption of switching tubes, and large differences in voltage and current. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description will help those skilled in the art better understand other advantages, objectives and features of the present invention.

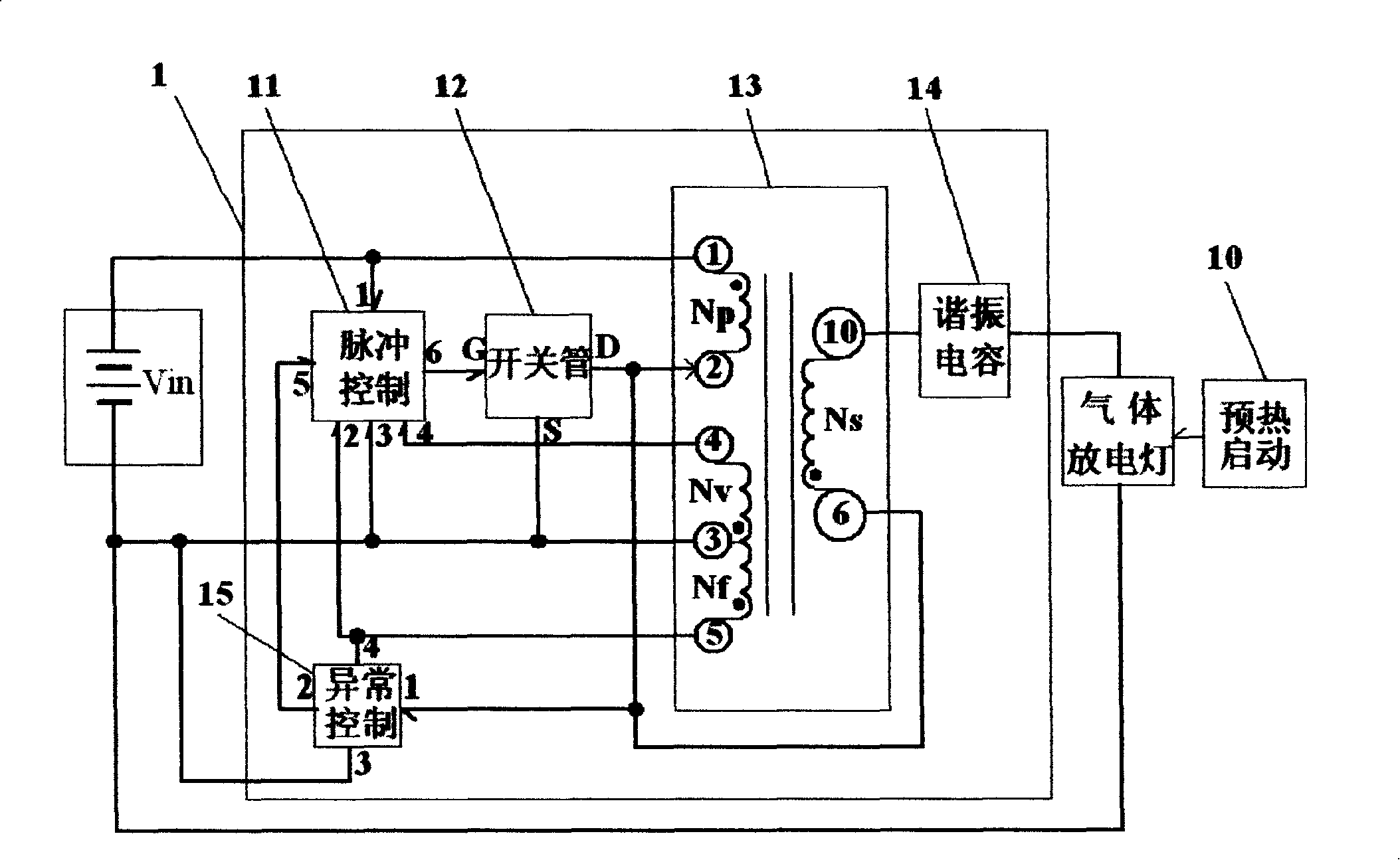

[0123] At first introduce the first embodiment of the device of the present invention, refer to figure 1 . figure 1 The driving device 1 of the gas discharge lamp shown is used to drive the gas discharge lamp with high-frequency AC to make it emit light. The high-frequency AC drive process uses a single resonant circuit; to drive the gas discharge lamp, there is no other double switch tube There are two resonant frequency problems in the circuit (half-bridge circuit), and the power control circuit can stabilize the output power under a wide voltage, and at the same time avoid the saturation of the magnetic core, thereby greatly improving the life of the circuit; the device 1 mainly includes : T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com