Container terminal in-process control and visual system

A production process control and container technology, applied in storage devices, transportation and packaging, load hanging components, etc., can solve the problems of arbitrary operation of loading and unloading drivers, lag of production information, and production constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

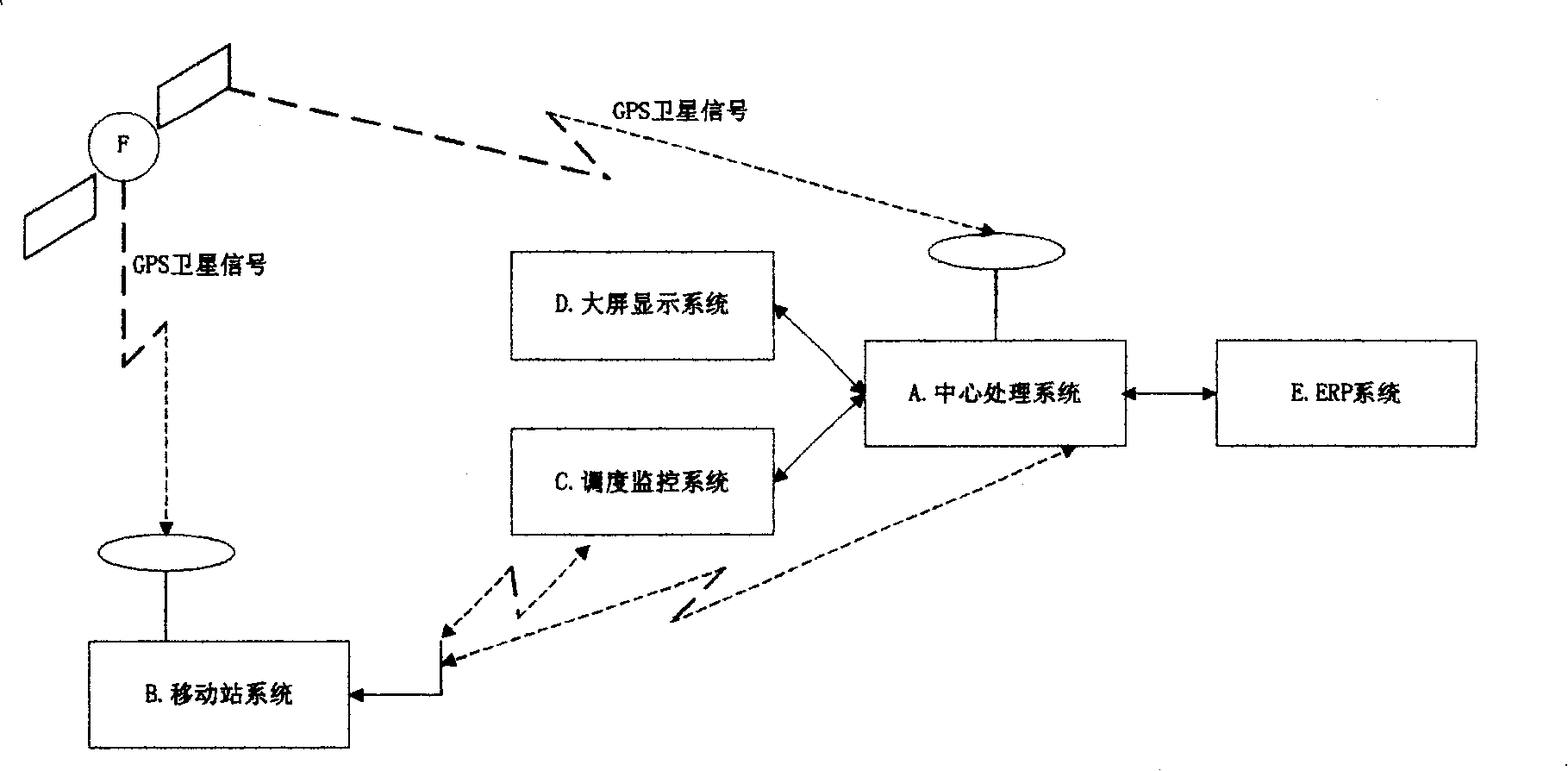

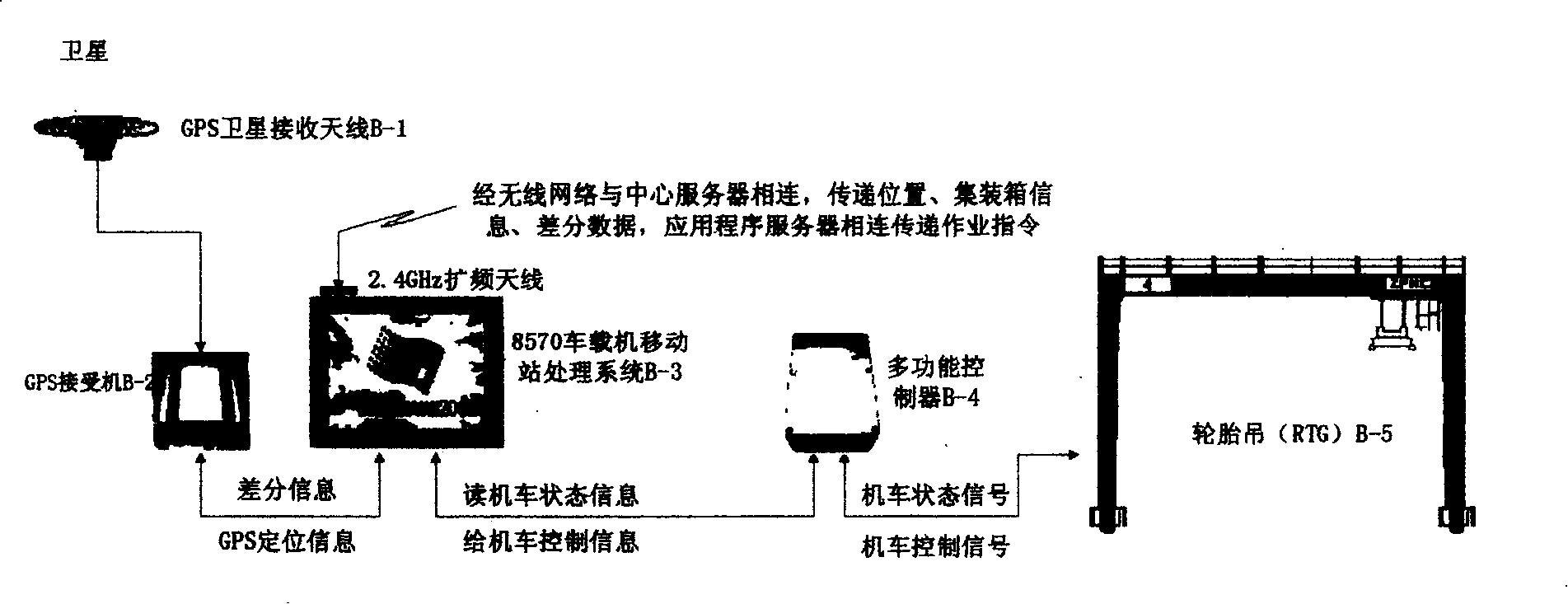

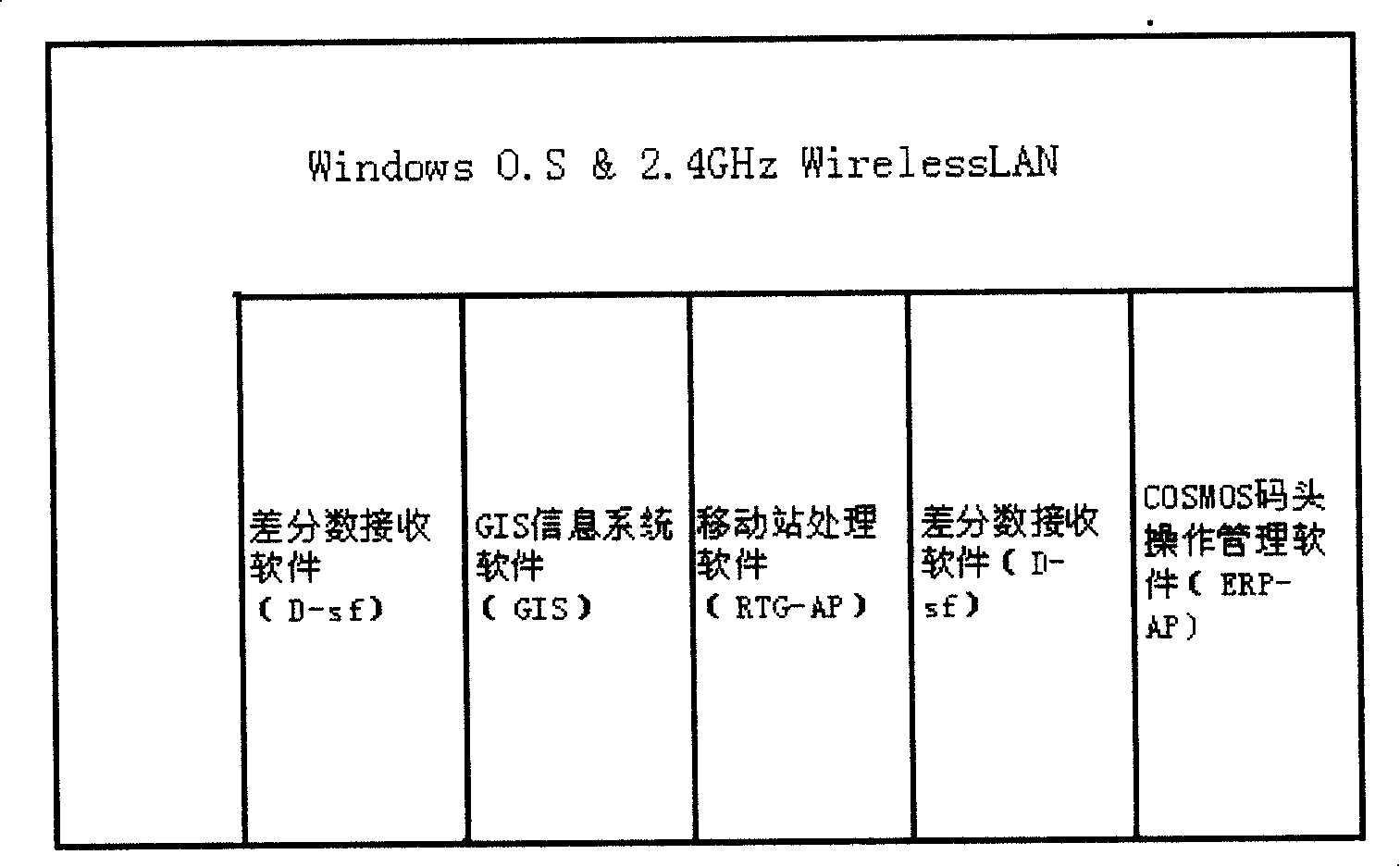

[0126]This container operation process control and visualization system is implemented in Tianjin Port Container Terminal Co., Ltd., which solves the demand for container production in the company's 3C domestic ports, and introduces global satellite positioning (GPS) and geographic information (GIS) technologies into the port container industry. Apply computer, communication, control, GIS, GPS, navigation, multimedia, DLP large screen and other high-tech, carry out comprehensive development, and carry out automatic data collection, Accurate positioning, dynamic tracking, fine-grained control of the production process, 3D visual operation of the driver, and 3D visual management of scheduling. It effectively solves the problems of arbitrariness of driver's operation, lag of production information and the restriction of special natural environment on production. The "container terminal production process control and visual management system" has created a container terminal with C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com