Coating type granular complex fertilizer product and production method thereof

A compound fertilizer and product technology, applied in chemical instruments and methods, potash fertilizers, silver compounds, etc., can solve problems such as fertilizer incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

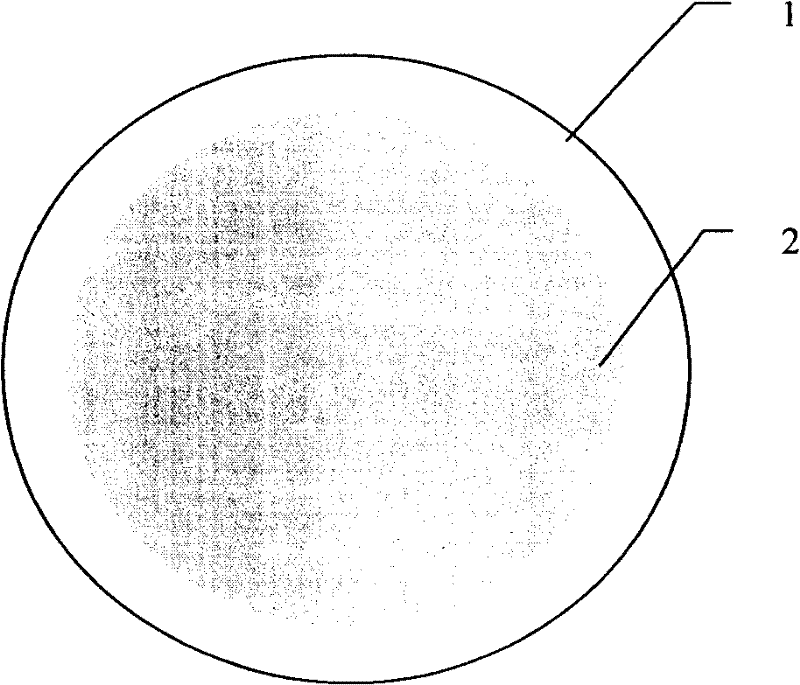

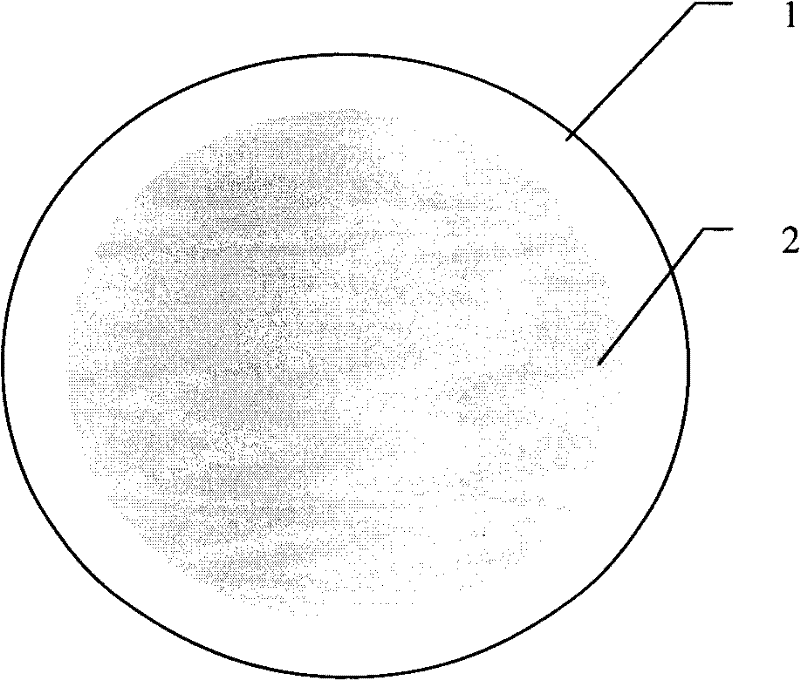

[0018] Example 1: The inner core (2) in the picture is produced by the ordinary disc agglomeration granulation method, that is, using ordinary compound fertilizer raw materials, adding a variety of trace elements, amino acids, etc., the disc agglomeration granulation method is used to produce particles with a diameter of φ1.0mm The inner core (2) of the product with a diameter of φ3.9mm, after being dried and cooled, particles with a smooth surface and no dust are selected by sieving, and then the surface of the inner core (2) is coated with 80% potassium sulfate slurry through multiple spray coatings. A dense coating layer (1) with a thickness of 0.4mm~1.5mm is formed. After two-stage drying and cooling, the surface of the finished particles is polished, rounded and sprayed to prevent hardening. A coated granular compound fertilizer product is shaped .

Embodiment 2

[0019] Example 2: The inner core (2) in the figure is produced by the ordinary disc agglomeration granulation method, that is, using ordinary compound fertilizer raw materials, adding a variety of trace elements, amino acids, etc., the disc agglomeration granulation method is used to produce particles with a diameter of φ1.0mm The inner core (2) of the product with a diameter of φ3.9mm, after being dried and cooled, the particles with a smooth surface and no dust are selected by screening, and then 90% high-concentration potassium sulfate fertilizer slurry is sprayed and coated on the surface of the inner core (2) several times , Form a dense coating layer (1) with a thickness of 0.4mm~1.5mm, after two-stage drying and cooling, the surface of the finished particles is polished, rounded and sprayed to prevent hardening. A coated granular compound fertilizer product is forming.

Embodiment 3

[0020] Example 3: The inner core (2) in the picture is produced by the ordinary disc agglomerate granulation method, that is, the ordinary compound fertilizer raw materials are used to add various trace elements, amino acids, etc., and the disc agglomerate granulation method is used to produce particles with a diameter of φ1.0mm The inner core (2) of the product with a diameter of φ3.9mm, after drying and cooling, the particles with a smooth surface and no dust are selected by screening, and then the surface of the inner core (2) is coated with 97% potassium chloride slurry by multiple spray coating , Form a dense coating layer (1) with a thickness of 0.4mm~1.5mm, after two-stage drying and cooling, the surface of the finished particles is polished, rounded and sprayed to prevent hardening. A coated granular compound fertilizer product is forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com