Car brake disk assembly jump measuring instrument

A technology of brake discs and measuring instruments, which is applied in the direction of measuring devices, vehicle testing, instruments, etc., can solve the problems of not being able to meet the measurement needs, the measurement results are greatly affected, and the measurement accuracy is low, so as to achieve convenient process management and long service life The effect of long length and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

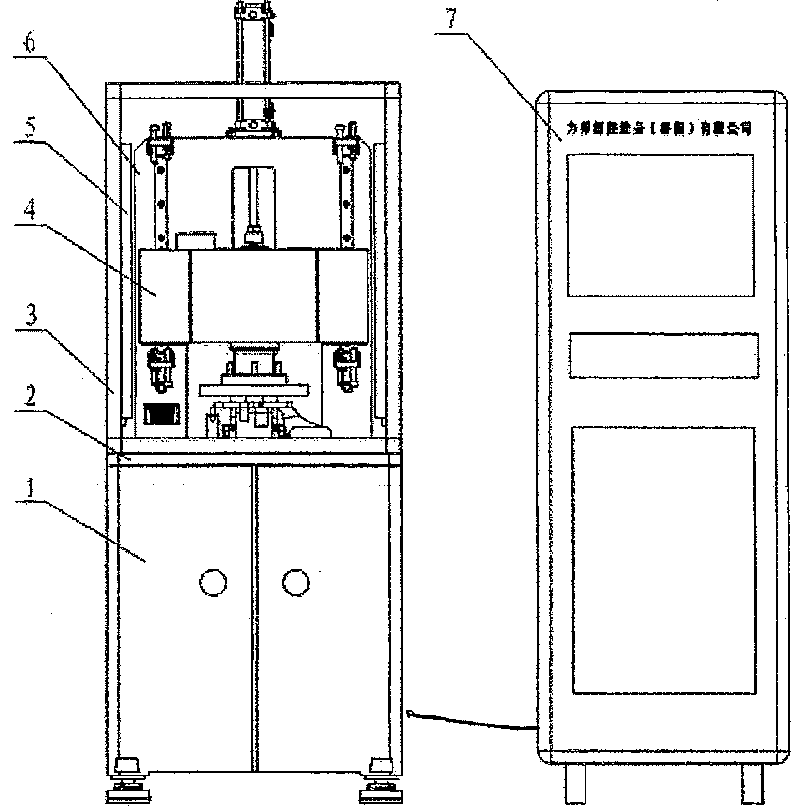

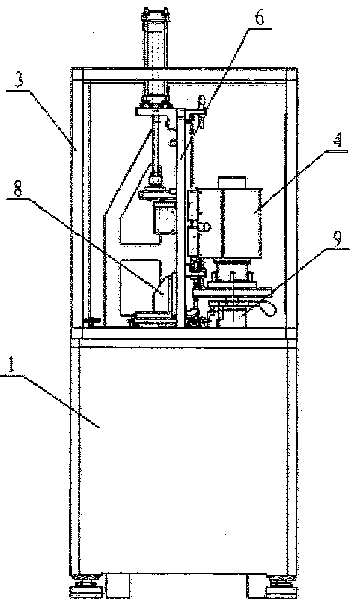

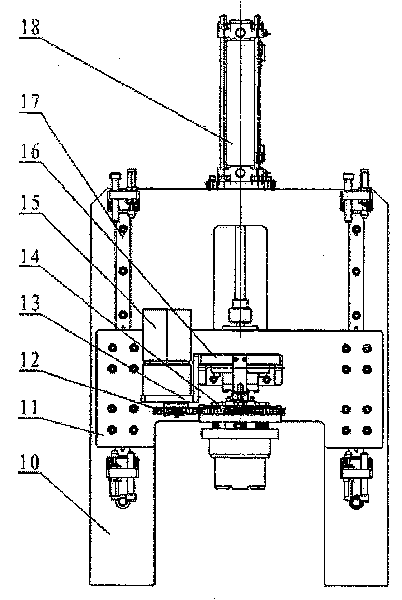

[0019] Depend on figure 1 , figure 2 It can be known that a car brake disc assembly runout measuring instrument includes an industrial microcomputer control electric box 7, an equipment body 1, an operating table 2, an equipment protective cover 3, a measuring protective cover 4, and a safety protection switch 5. 2 is equipped with a brake disc surface runout measurement part 8, a pressing rotating part 6 and a brake disc assembly positioning platform 9; Bracket 13, large gear 14, driving motor 15, bearing support 16, large guide rail 17, lifting cylinder 18, cylinder upper support 19, cylinder lower support 20, signal trigger 22, pressure relief spring 23, floating drive head 24 Composition: Brake disk surface runout measuring part 8 is provided with small guide rail support 25, small guide rail 26, small guide rail sliding plate 27, measuring support 28, sensor support 29, retractable linear sensor 30, measuring small cylinder 32 and connecting plate 31.

[0020] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com